90-830234R3 DECEMBER 1997 LOWER UNIT - 6A-9

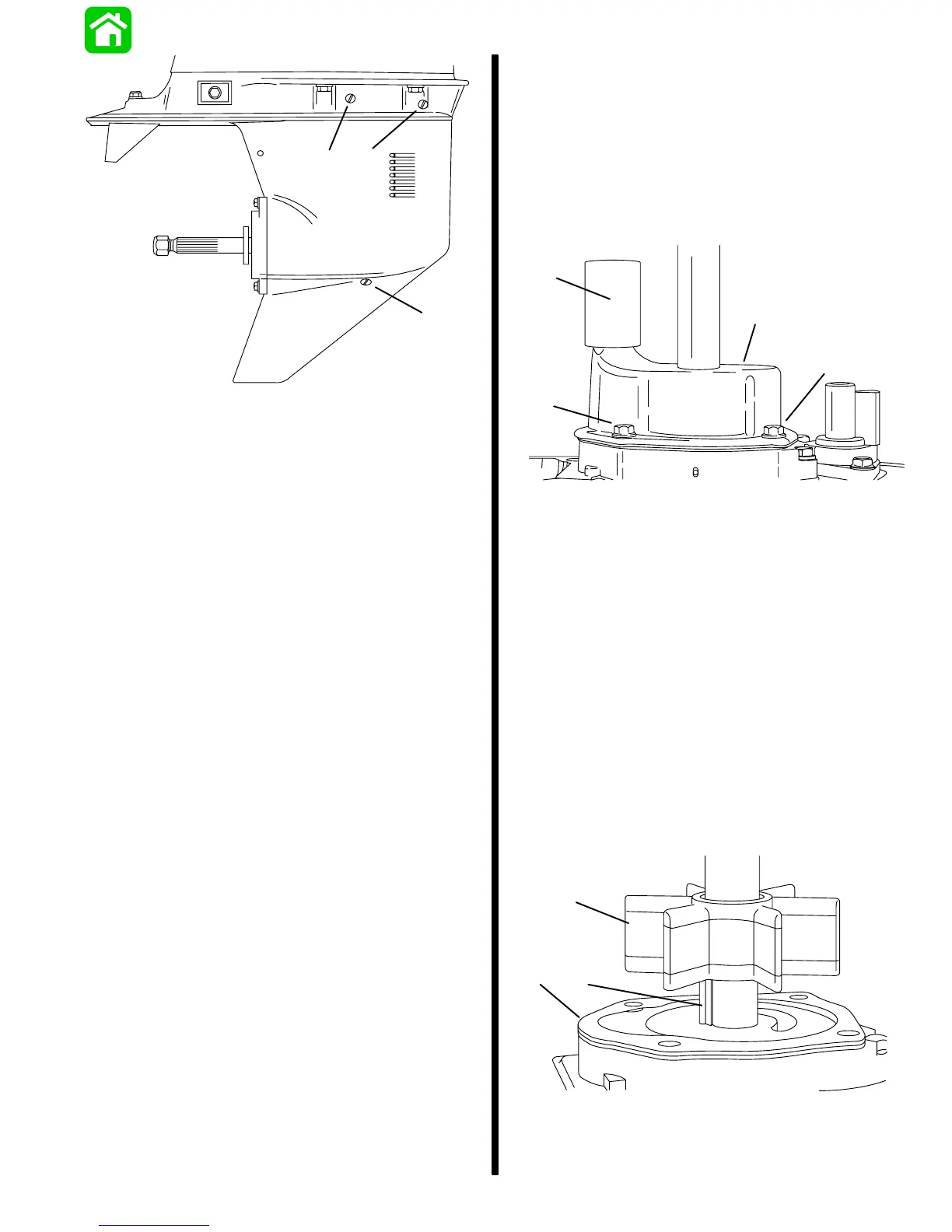

b

c

a

53922

a - Oil Level Screw

b - Fill/Drain Screw

c - Vent Screw

2. Inspect gear lubricant for metal particles (lubri-

cant will have a “metal flake” appearance). Pres-

ence of fine metal particles (resembling powder)

on the drain plug bar magnet indicates normal

wear. The presence of metal chips on the drain

plug bar magnet indicates the need for gear

housing disassembly and component inspection.

3. Note color of gear lubricant. White or cream color

MAY indicate presence of water in lubricant. Gear

lubricant which has been drained from a gear

case recently in operation will have a yellowish

color due to lubricant agitation/aeration. Gear

lube which is mixed with assembly lubricant

(Special Lube 101 or 2-4-C w/Teflon will also be

creamy white in color. This is normal and should

not be confused with the presence of water. If wa-

ter is suspected to be present in gearcase, a

pressure check of gearcase should be made

(with no lubricant in gearcase). Gearcase should

hold 10 to 12 psi (68 – 82 kPa) of pressure for 5

minutes without leaking down. Pouring a portion

of the gear lubricant into a glass jar and allowing

the lubricant to settle will allow any water in the

lube to separate and settle to the bottom of the jar.

4. Presence of water in gear lubricant indicates the

need for disassembly and inspection of oil seals,

seal surfaces, O-rings, water pump gaskets as

well as gear housing components for damage. If

gearcase is rebuilt, gearcase should be pressure

checked before filling with lubricant.

Water Pump

1. If water tube seal stayed on water tube (inside of

drive shaft housing) when gear housing was re-

moved, pull water tube seal from water tube.

2. Replace water tube seal, if damaged.

3. Remove 4 bolts, washers, and isolators.

4. Remove cover.

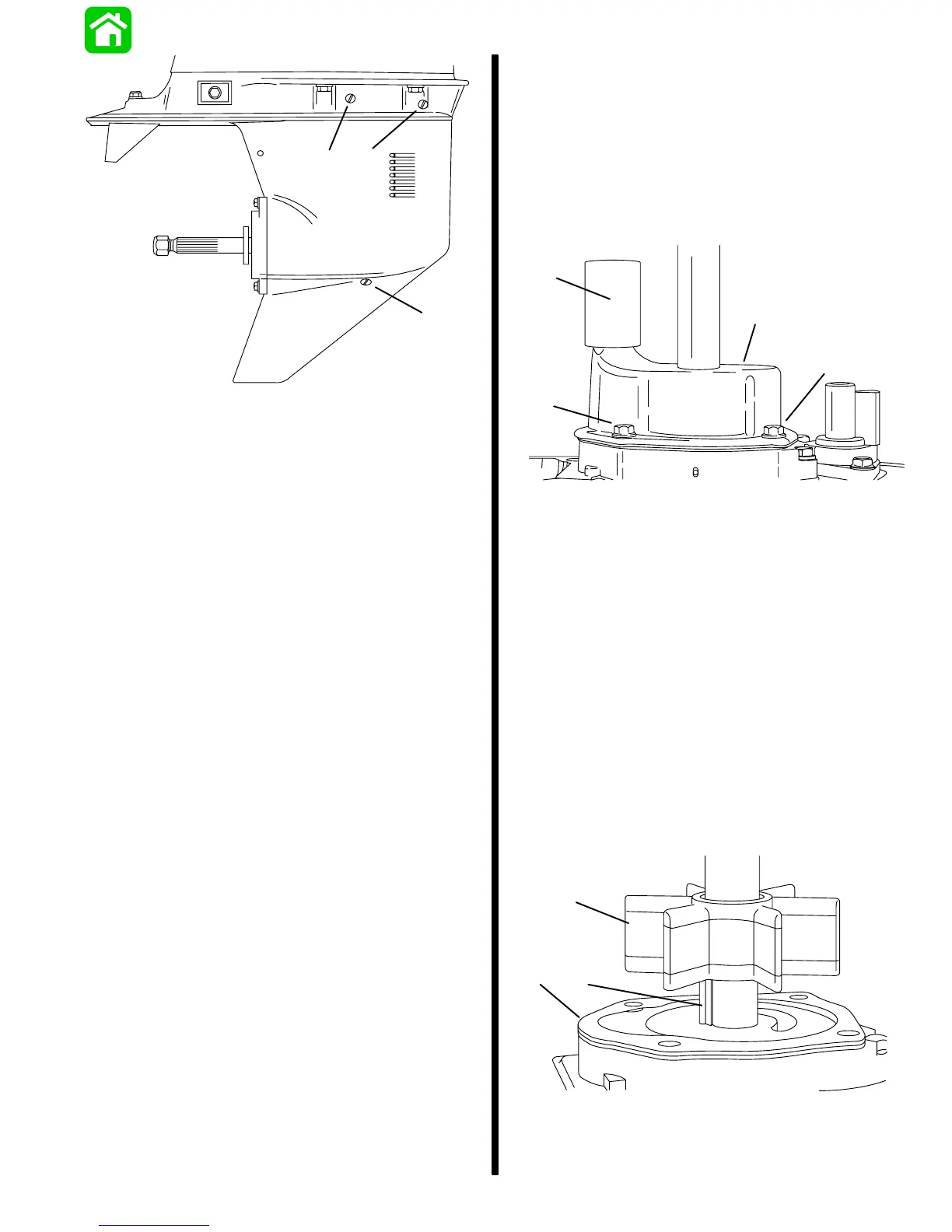

c

b

b

a

19212

a - Water Tube Seal

b - Bolts (4 each)

c - Cover

IMPORTANT: The circular groove formed by the

impeller sealing bead should be disregarded

when inspecting cover (Step 5) and plate (Step 9),

as the depth of the groove will not affect water

pump output.

5. Replace cover if thickness of steel at the dis-

charge slots is 0.060 in. (1.52mm) or less, or if

groove(s) (other than impeller sealing bead

groove) in cover roof are more than 0.030 in.

(0.76mm) deep.

6. Lift impeller, drive key, and gasket from drive

shaft.

c

b

a

19220

a - Impeller

b - Drive Key

c - Gasket

Loading...

Loading...