90-830234R3 DECEMBER 1997 LOWER UNIT - 6B-11

Lubricating the Drive Shaft

Bearing

Recommended Lubrication - Use 2-4-C w/Teflon.

IMPORTANT: It is important that you do not use

a general-all-purpose grease for this bearing.

The lubricant we recommend is a water resistant

grease of the proper consistency for this applica-

tion. If you use a substitute grease, be sure that

it is water resistant and of the same consistency.

Frequency of lubrication - We recommend lubricat-

ing the drive shaft bearing after each day’s use and

after every 10 hours of operation. After every 30

hours of operation, pump in extra grease to purge out

any moisture.

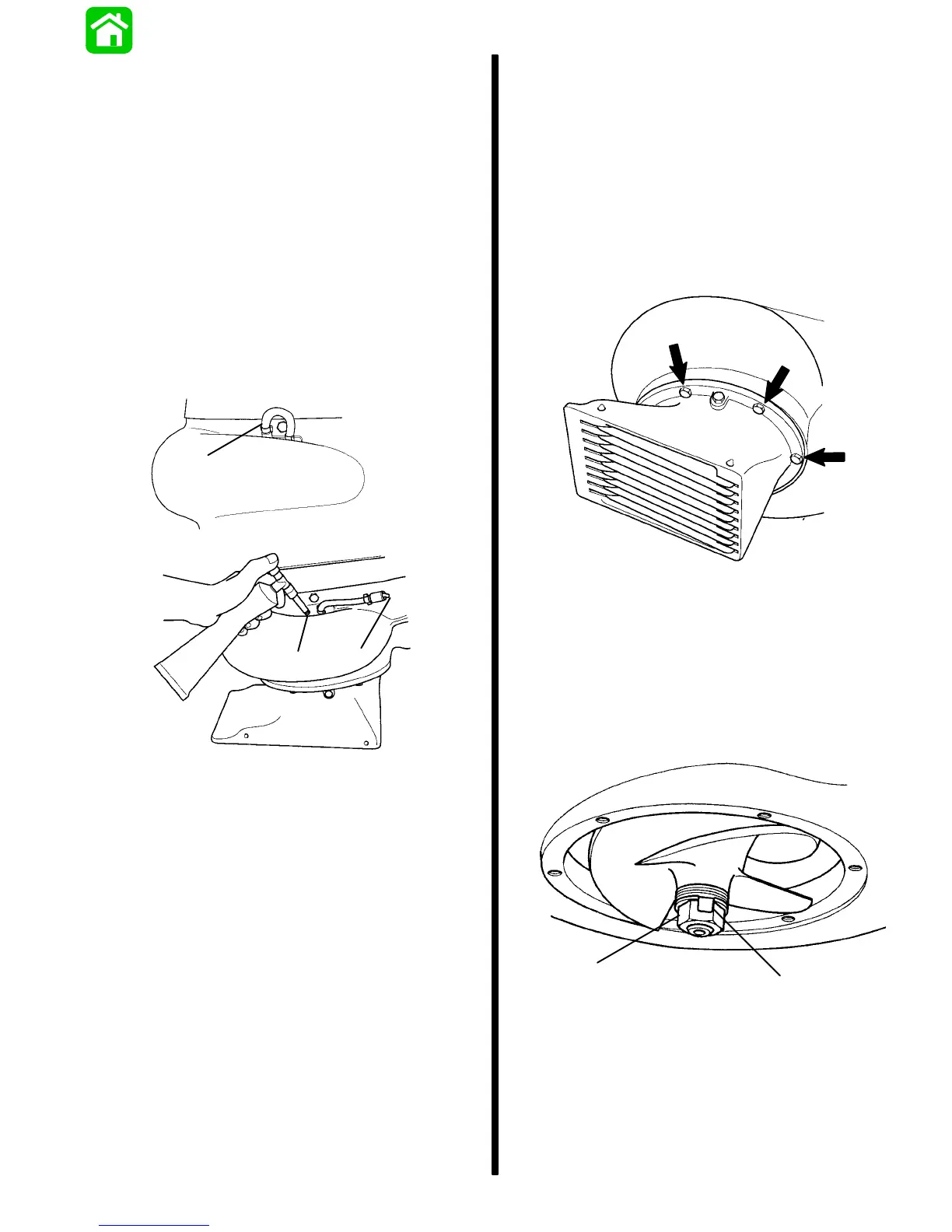

a

b

c

a - Vent Hose

b - Grease Gun

c - Grease Exiting Vent Hose

Lubricating Procedure - Pull vent hose (a) off the

grease fitting. Pump in grease (b) through the grease

fitting (using the grease gun provided) until excess

grease starts to exit the vent hose (c).

Reconnect the vent hose (a) onto the grease fitting

after greasing.

After 30 hours of operation, pump in extra grease to

purge out any moisture. Visually inspecting the

purged grease at this time will give you an indication

of conditions inside the bearing housing. A gradual

increase in moisture content, indicates seal wear. If

the grease begins to turn dark, dirty gray, the drive

shaft bearing and seals should be inspected and re-

placed if necessary. Some discoloration of the

grease is normal during the break-in period on a new

set of seals.

Impeller Removal and

Installation

REMOVAL

1. Shift outboard to NEUTRAL (N) position.

2. Remove spark plug leads to prevent engine from

starting.

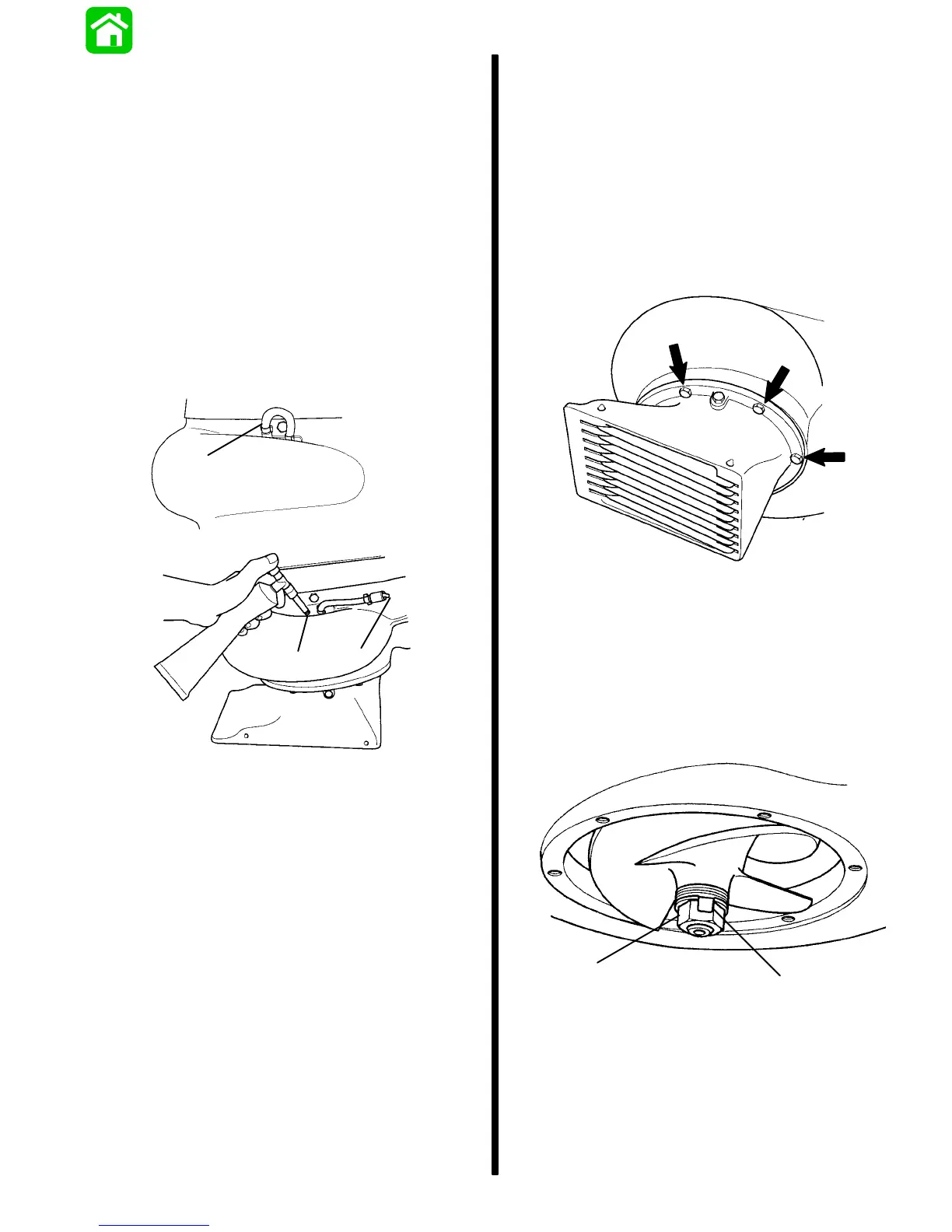

3. Remove the water intake housing that is fastened

with six screws.

4. Straighten the bent tabs (a) on the impeller nut re-

tainer and remove the impeller nut (b).

5. Pull impeller straight off the shaft. If the impeller

is tight, use a hammer and block of wood to rotate

the impeller (clockwise) on the shaft until the key-

way is directly above the flat on the shaft. This will

free the jammed key and allow removal.

a

b

a-Tab

b - Nut

Loading...

Loading...