4. PARAMETERS FOR POSITIONING CONTROL

4 − 24

4.4.1 Relationships among the speed limit value, acceleration time, deceleration time, and rapid stop

deceleration time

The speed limit value is the maximum speed during positioning/zeroing.

The acceleration time is the time taken to reach the set speed limit value from the

start of positioning.

The deceleration time and rapid stop deceleration time are the time taken to effect

a stop from the set speed limit value.

Accordingly, the actual acceleration time, deceleration time, and rapid stop

deceleration time are faster, because the positioning speed is faster than the

speed limit value.

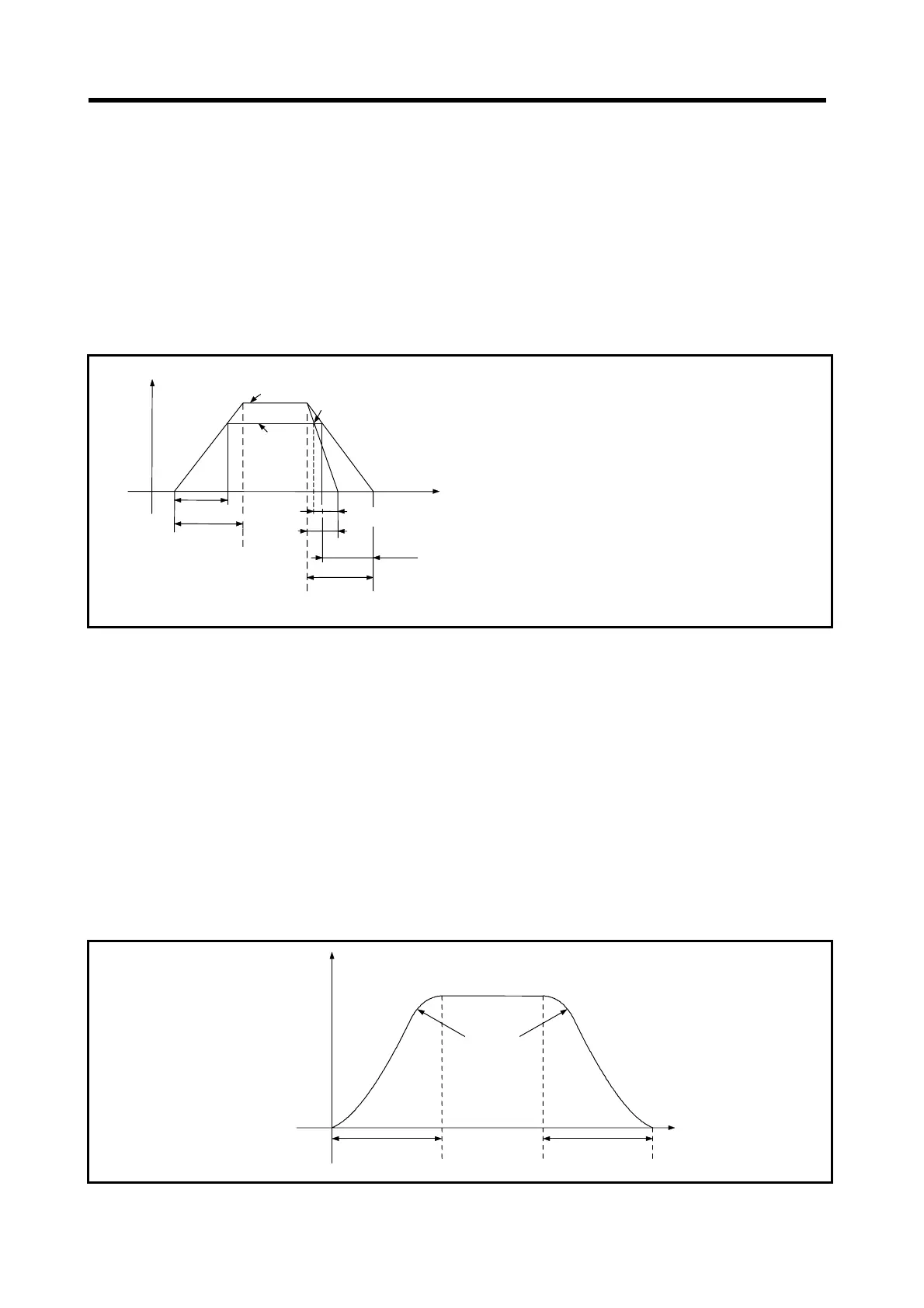

1) Actual acceleration time

Time take to reach the positioning speed

set in the servo program

2) Actual rapid stop deceleration time

Time taken to effect a rapid stop from the

positioning speed set in the servo program

3) Actual deceleration time

Time taken to stop from the positioning

speed set in the servo program

Set deceleration time

Speed

Speed limit value

Occurrence of rapid stop cause

Time

Set rapid stop

deceleration

time

3) Actual deceleration time

Set acceleration

time

1) Actual accele-

ration time

2) Actual rapid stop

deceleration time

Positioning

speed set in

the servo

program

Fig. 4.2 Relationships among the Speed Limit Value, Acceleration Time,

Deceleration Time, and Rapid Stop Deceleration Time

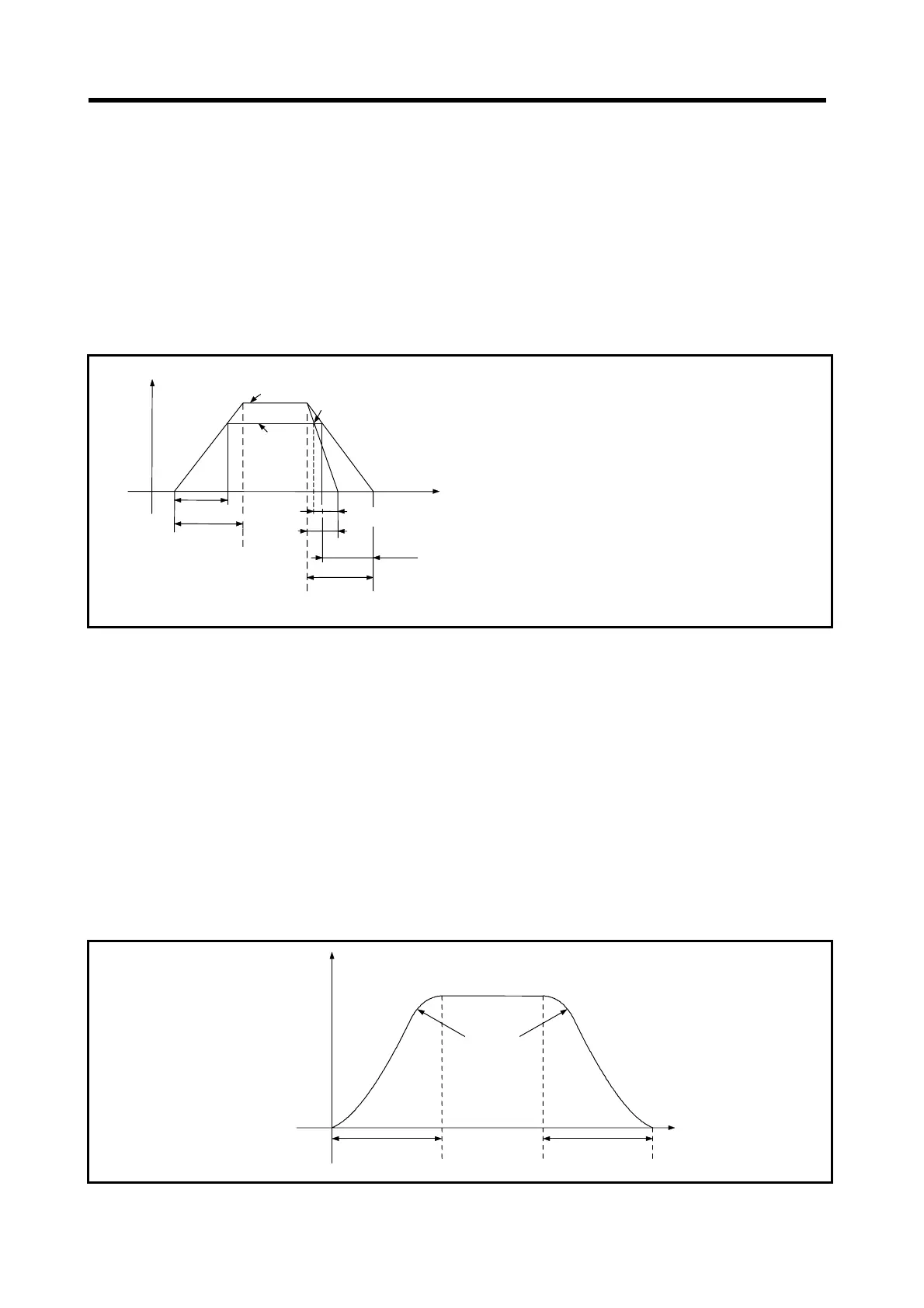

4.4.2 S-curve ratio

The S-curve ratio used when S-pattern processing is used as the acceleration and

deceleration processing method can be set. (For details on S-pattern processing,

see Section 7.1.7.)

The setting range for the S-curve ratio is 0 to 100 (%).

If a setting that is outside the applicable range is made, an error occurs on starting,

and control is executed with the S-curve ratio set at 100%.

Errors are set in the servo program setting error area (D9190).

Setting an S-curve ratio enables acceleration and deceleration processing to be

executed gently.

The graph for S-pattern processing is a sine curve, as shown below.

V

t

0

Sine curve

Acceleration

time

Deceleration

time

Positioning speed

Time

Loading...

Loading...