Chapter 11 Selection

11–7

11-3-3 Continuous characteristics

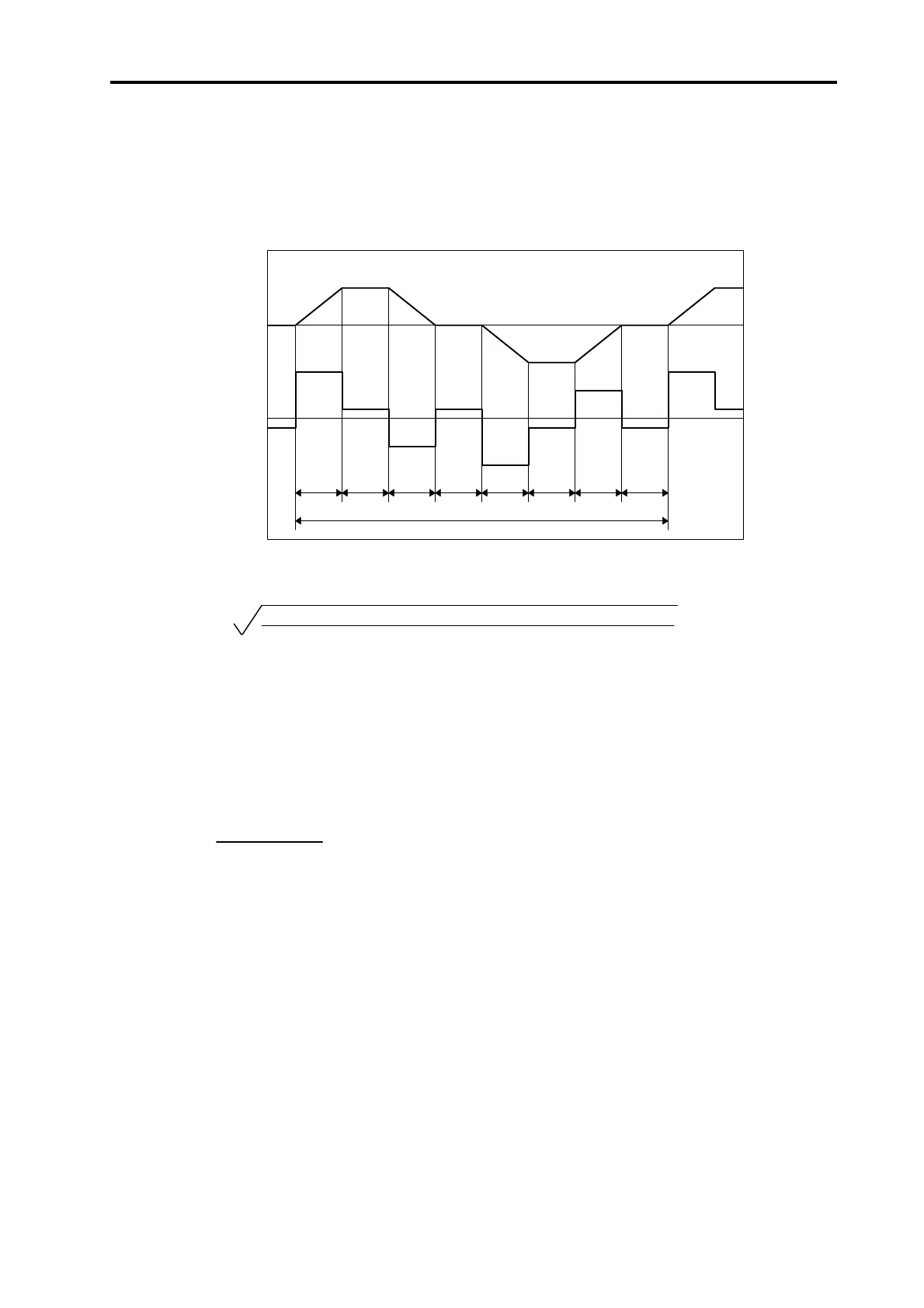

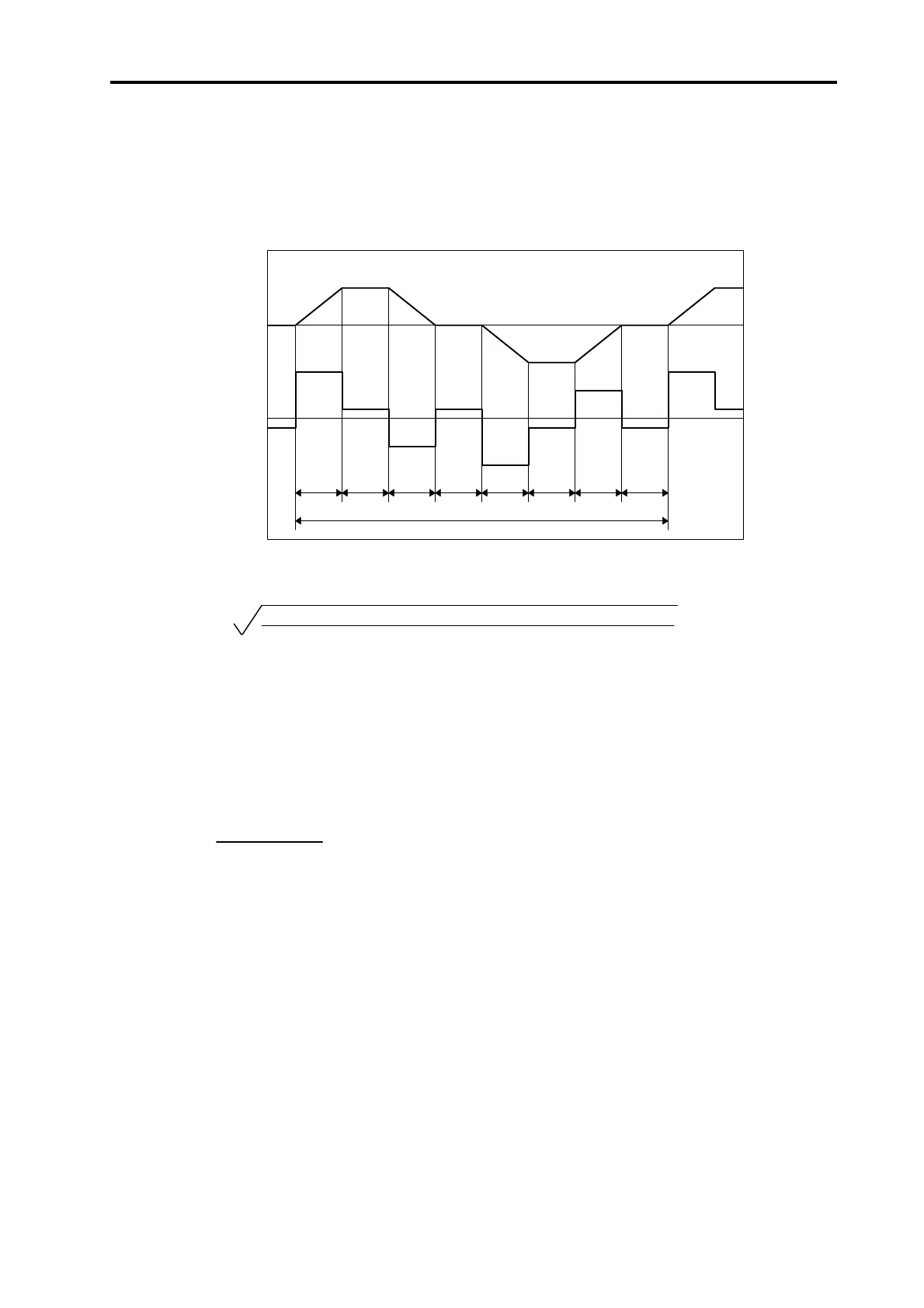

A typical operation pattern is assumed, and the motor's continuous effective load torque (Trms) is

calculated from the motor shaft conversion and load torque. If numbers ① to ⑧ in the following

drawing were considered a one cycle operation pattern, the continuous effective load torque is

obtained from the root mean square of the torque during each operation, as shown in the expression

(11-3).

Motor

torque

Motor

speed

0

0

3

2

t1 t2 t3 t4

t0

T1

T4

T5

T7

t5 t6 t7 t8

① ② ③ ④ ⑤ ⑥ ⑦ ⑧

Fig. 11-1 Continuous operation pattern

Trms =

T1

·t1 + T2

·t2 + T3

·t3 + T4

·t4 + T5

·t5 + T6

·t6 + T7

·t7 + T8

·t8

.................. (11-3)

Select a motor so that the continuous effective load torque (Trms) is 80% or less of the motor rated

torque (Tra) (stall torque (Tst) in the HC, HAN Series).

Trms ≤ 0.8 • Tra (or 0.8 • Tst) ................................................. (11-4)

The amount of acceleration torque (Ta) shown in tables 11-6 and 11-7 is the torque to accelerate the

load inertia in a frictionless state. It can be calculated by the expression (11-5). (For linear

acceleration/deceleration)

Ta =

(J

L

+ J

M

)

×

N

95.5 × ta

(N•m) ................................................. (11-5)

N : Motor reach speed (r/min)

JL : Motor shaft conversion load inertia (× 10

–4

kg·cm

2

)

JM : Motor inertia (× 10

–4

kg·cm

2

)

ta : Linear acceleration/deceleration time constant (msec)

Loading...

Loading...