Chapter 5 Installation

5–4

5-1-4 Tolerable load of axis

(1) Using the flexible coupling, set the axis core deviation to less than the tolerable radial load of the

axis.

(2) When using a pulley, sprocket and timing belt, select so that the loads are within the tolerable

radial load.

(3) A rigid coupling must not be used as it will apply an excessive bending load on the axis to break.

Servomotor Tolerable radial load Tolerable thrust load

HS-MF23 88N L=25 59N

HS-RF43/73 392N L=58 196N

HS-SF52/53/102/103 392N L=58 196N

HS-SF202 2058N L=79 980N

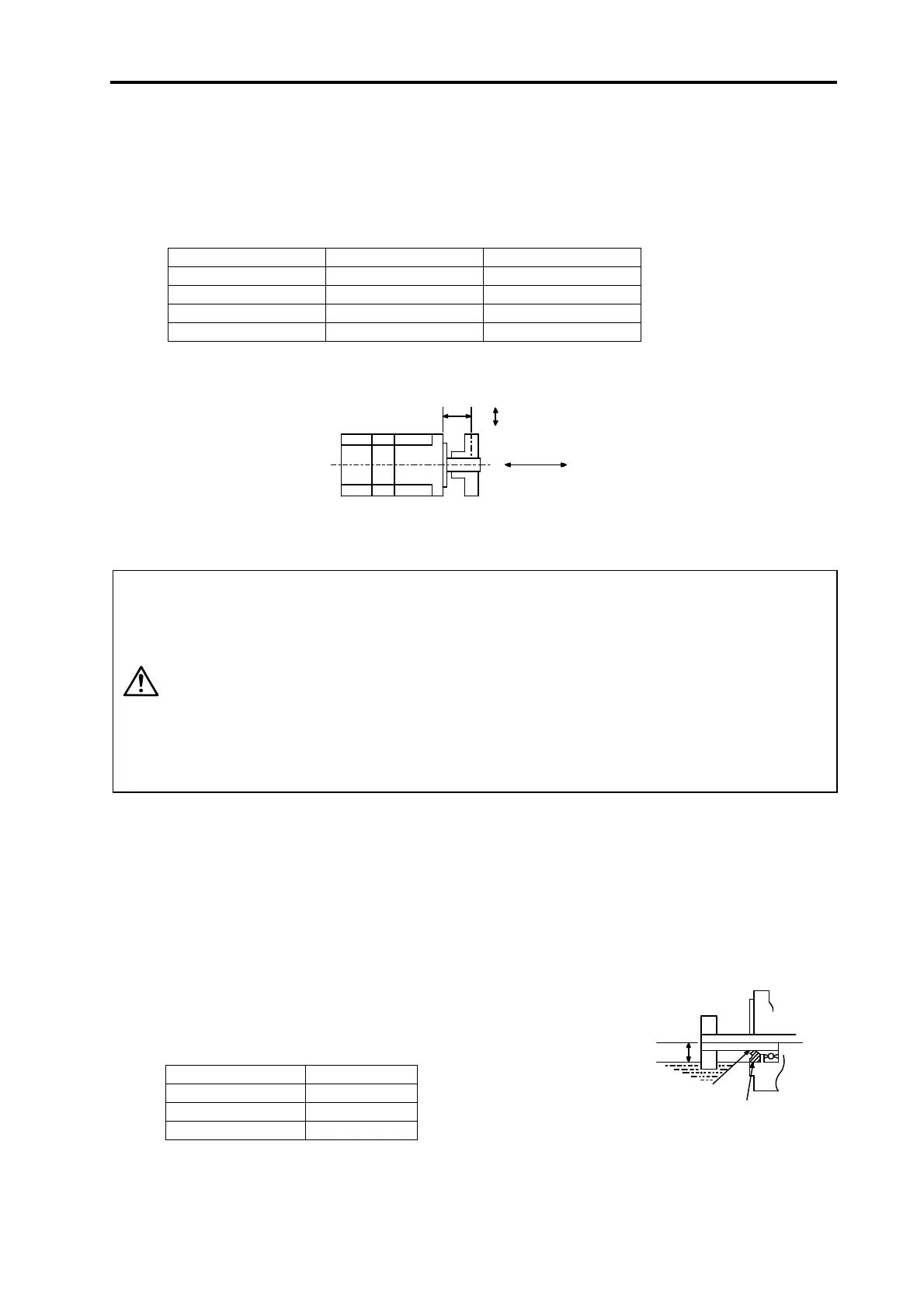

Caution: The symbols in the table follow the drawing below.

Radial load

Thrust load

L

L : Length from flange isntallation surface to center of load weight [mm]

CAUTION

1. When coupling with a ball screw, etc., use a flexible coupling, and keep the

shaft core deviation to below the tolerable radial load.

2. When installing the pulleys or gears on the motor shaft, the radial load will

increase as the diameter of these parts decreases. Consider this when

designing the machine.

3. When using a timing belt, adjust so that the radial load (double the tension)

generated from the tension is less than the values given above.

4. In a machine having a thrust load, such as a worm gear, provide a separate

bearing on the machine side so that the a load exceeding the tolerable

thrust load is not applied on the motor.

5. Do not use a rigid coupling as an excessive bending load will be applied on

the shaft and could cause the shaft to break.

5-1-5 Oil and waterproofing measures

(1) The servomotor does not have a precise water or oil-proof structure. The type (IP class) following

the IEC standards is indicated as the intelligent servomotor's protection type. These standards are

the short-time performance standards, so make sure that the motor surface is not subject to fluids

and that fluids do not accumulate. If cutting oil, etc., could enter, always provide a protective

cover. Always consider the cover seams, edges, shapes and dimensions. Note that the IP class

does not indicate the corrosion resistance level.

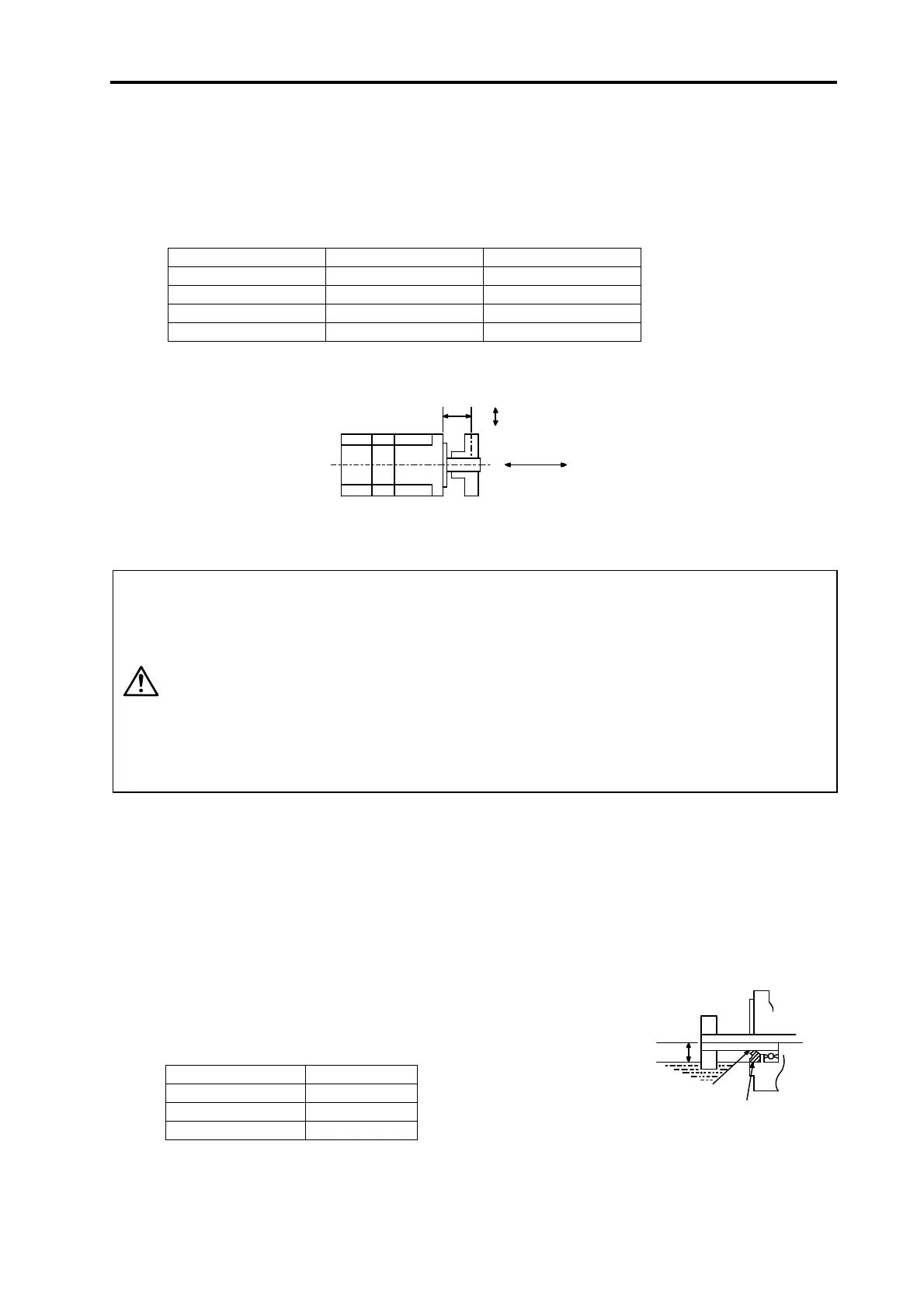

(2) When a gear box is installed on the servomotor, make sure that

the oil level height from the center of the shaft is higher than the

values given below. Open a breathing hole on the gear box so

that the inner pressure does not rise.

Servomotor Oil level (mm)

HS-MF23 12

HS-RF43, 73, -SF103 20

HS-SF202 25

Servomotor

Gear

Lip

Oil level

Oil seal

Loading...

Loading...