44473001TH Rev.1

237 /

Oki Data CONFIDENTIAL

7. TROUBLESHOOTING PROCEDURES

Check item Check operation

Actions for NG

results

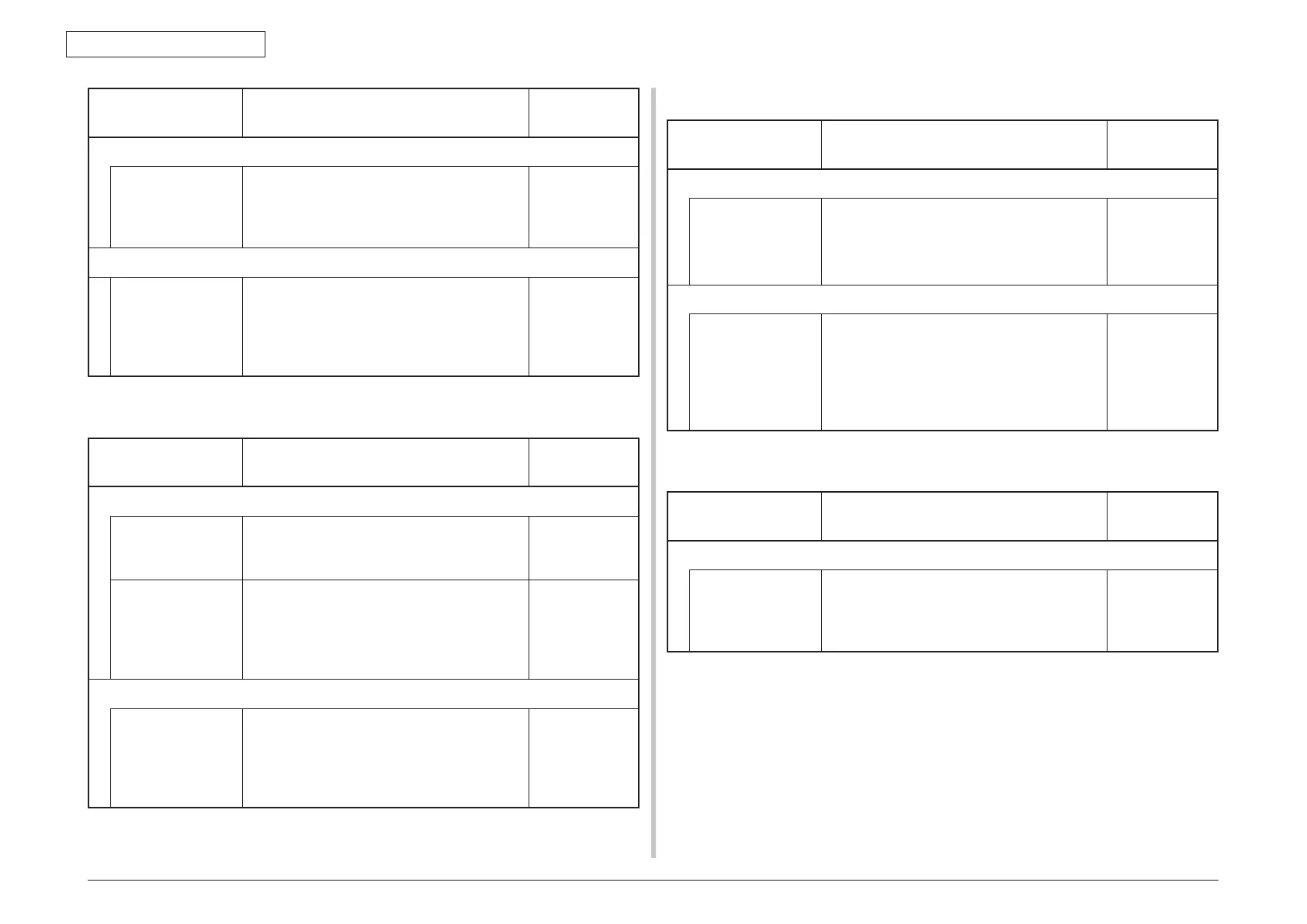

(8-2-3) Check condition of the paper running path

Paper inverting

tr

ansport path

Check that any foreign materials such as paper

chip or blue do not exist that hampers the

smooth movement of paper in the paper inverting

transport path.

Remove

the foreign

material.

(8-2-4) Motor operation check

Duplex pull-in/

reversing roller and

its pinch roller

Check if the pull-in/reversing roller of the Duplex

unit contacts or not with the pinch roller of the

cover side when the Duplex rear cover is closed.

(Does the pinch roller rotate when the roller is

rotating?)

Replace the

rear cover.

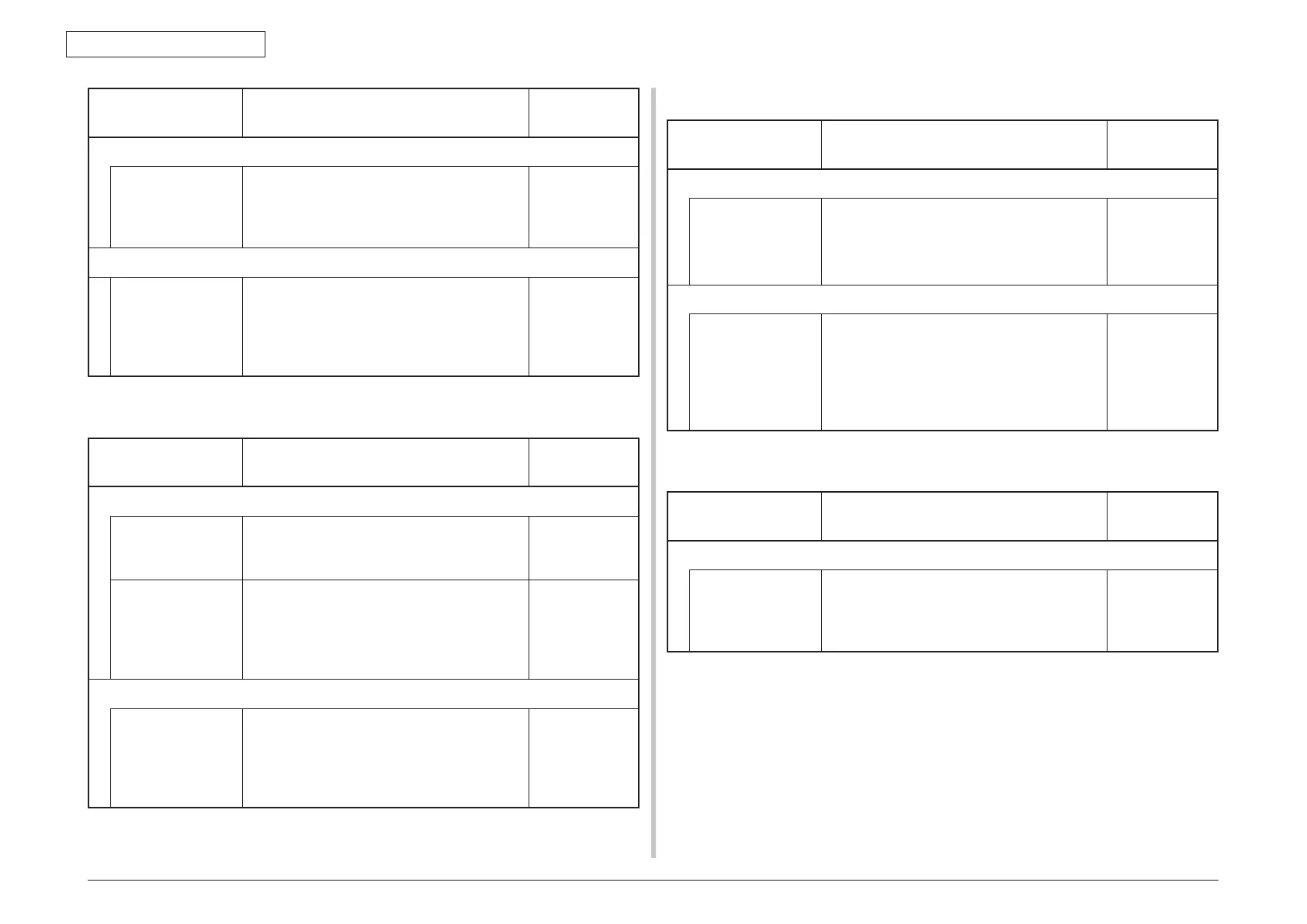

(8-3) Two-sided printing jam occurs in the process of reversing paper.

Check item Check operation

Actions for NG

results

(8-3-1) Sensor lever operation check

DUP-R sensor lever Open the rear cover. Touch the Dup-IN sensor

lever to check if its movement is unsmooth or not.

Replace the

DUP-R sensor

lever

DUP-R sensor Confirm that the sensor signals are normally

detected by using the SWITCH SCAN function of

the self-diagnostic mode.

Replace the

CU/PU board,

the sensor or

its connection

cord.

(8-3-2) Motor operation check

Fuser motor Visually check whether paper started being

reversed.

When no paper reversing operation has

performed, check whether the planet gear at the

lower right side of the fuser moves smoothly.

R

e

place the

planetary gear.

(8-4) Two-sided printing jam occurs during transporting paper inside the Duplex unit.

Check item Check operation

Actions for NG

results

(8-4-1) Sensor lever operation check

Dup-R, Dup-F

se

nsor lever

Open the top cover, remove the image drums

and the belt unit and check the operation of the

DUP-F sensor lever.

Replace the

sensor lever.

(8-4-2) Sensor check

Check the detection

condition of the

sensor signal

Confirm that the sensor signals are normally

detected by using the SWITCH SCAN function of

the self-diagnostic mode.

Check sensor detection with paper in the duplex

unit, and with it removed from the duplex unit.

Replace the

CU/PU board,

appropriate

sensor(s) or

connection

cord(s).

(8-5) Paper is not supplied from the Duplex unit to the regist roller.

Check item Check operation

Actions for NG

results

(8-5-1) Clutch operation check

Duplex clutch Confirm that the Duplex clutch works normally

by using the Motor & Clutch Test of the self-

diagnostic mode.Confirm it by listening to the

sound.

Replace the

CU/PU board

or the clutch.

Loading...

Loading...