262

Ratio Conversion Function Section 6-8

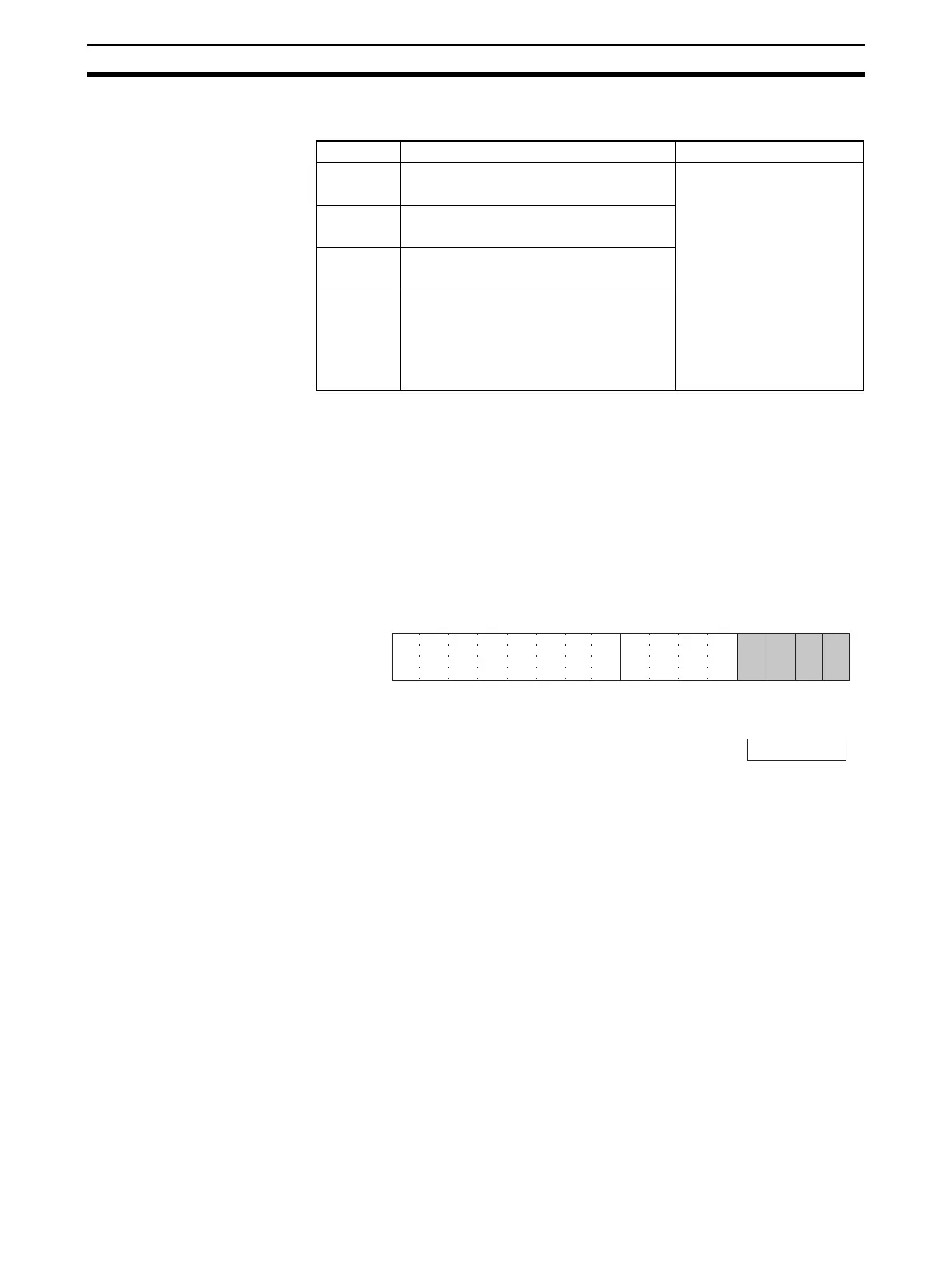

To specify the output hold function, use a Programming Device to set the DM

Area words D(m+2) to D(m+5) as shown in the following table.

For the DM word addresses, m = D20000 + (unit number x 100).

Note After specifying the DM settings from a Programming Device, it will be neces-

sary to either turn the power to the PLC OFF and ON, or turn ON the Special

I/O Unit Restart Bit to transfer the contents of the DM settings to the Special I/

O Unit.

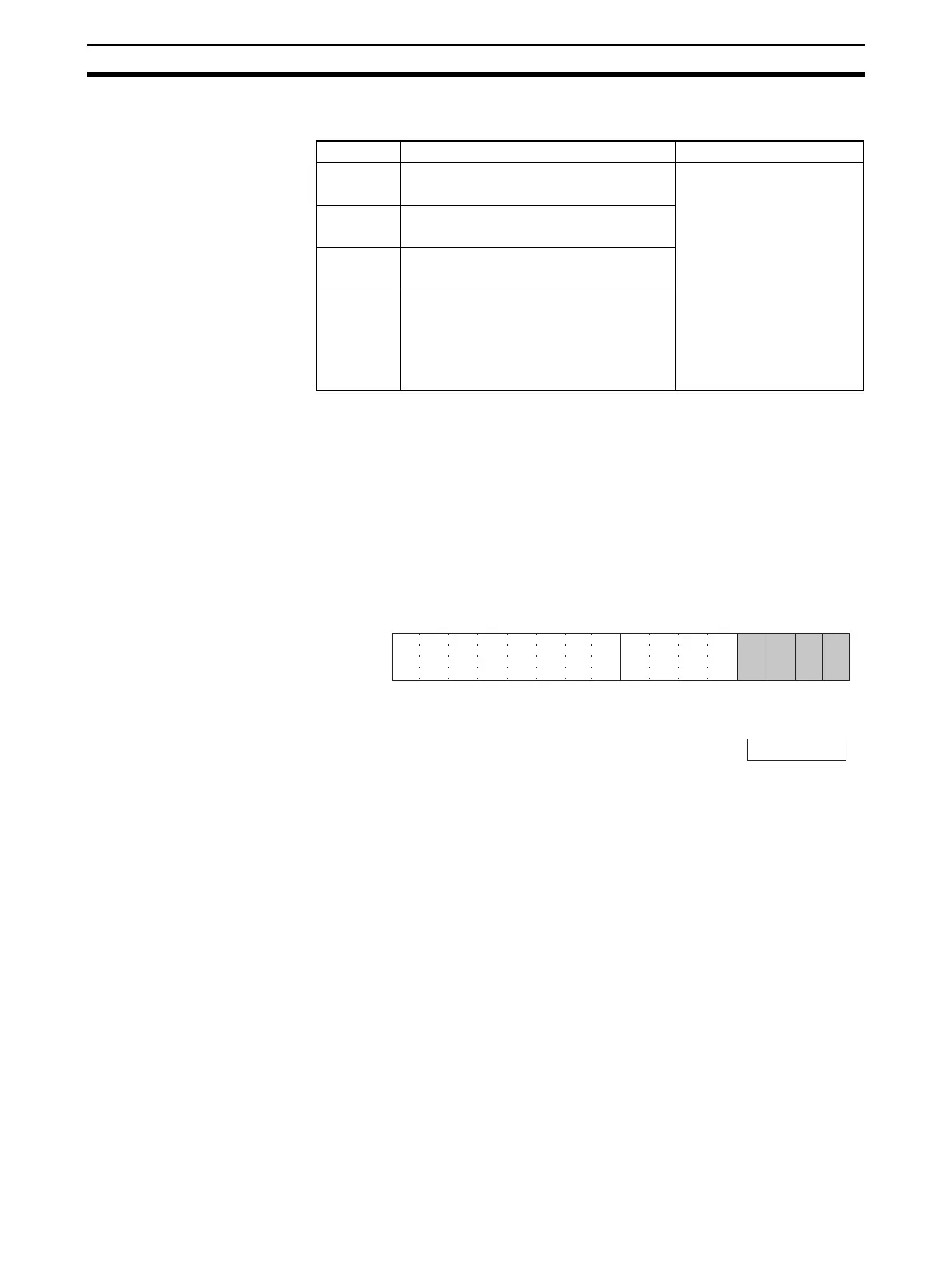

6-7-3 Output Setting Errors

If the analog output set value is greater than the specified range, a setting

error signal will be stored in CIO word n+9 (bits 00 to 03).

For the CIO word addresses, n = CIO 2000 + (unit number x 10).

The voltage for an output number at which a setting error has occurred will be

output according to the output hold function.

6-8 Ratio Conversion Function

The Analog I/O Unit has a ratio conversion function that enables it to perform

analog-to-analog conversions by itself, without utilizing the PLC. It can use

either Loop 1 (input number 1

→ output number 1), Loop 2 (input number 2 →

output number 2), Loop 3 (input number 3 → output number 3), or Loop 4

(input number 4

→ output number 4).

Input 1 → Ratio bias calculation → Output 1

Input 2

→ Ratio bias calculation → Output 2

Input 3

→ Ratio bias calculation → Output 3

Input 4 → Ratio bias calculation → Output 4

DM word Function Set value

D(m+2) Output 1: Output status when stopped xx00: CLR

Output 0 or mini-

mum value of range

(–5%).

xx01: HOLD

Hold output value

prior to stop.

xx02: MAX

Output maximum

value of range

(105%).

Set any value in the leftmost

bytes (xx).

D(m+3) Output 2: Output status when stopped

D(m+4) Output 3: Output status when stopped

D(m+5) Output 4: Output status when stopped

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Bit

Output 2

Output 1

Word n+9

When a setting error is detected

for a particular output, the corre-

sponding bit turns ON. When the

error is cleared, the bit turns OFF.

Output 4

Output 3

Loading...

Loading...