Tool Flange Replacement Procedure

Use the following procedure to replace the tool flange on the z-axis quill if necessary.

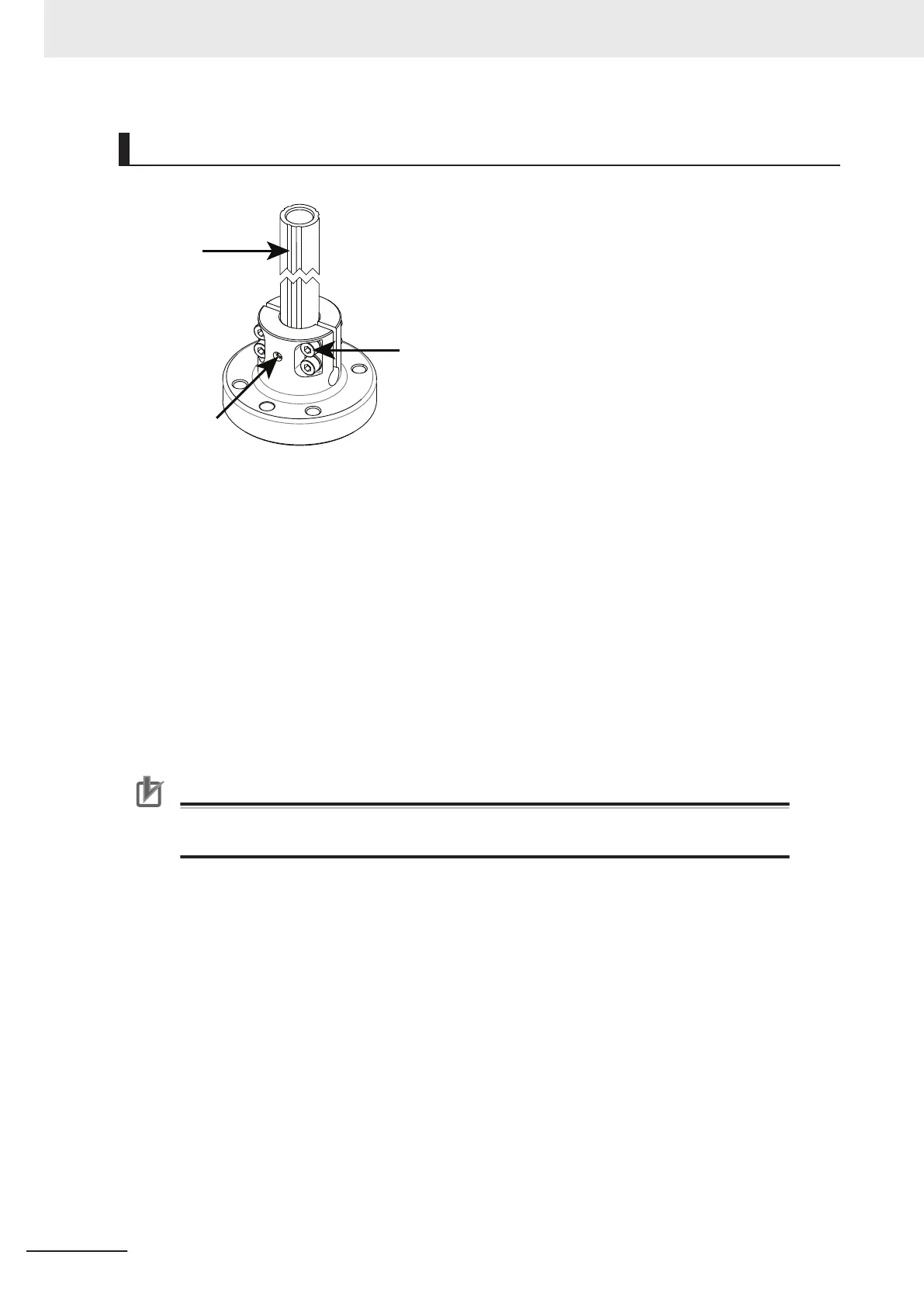

Quill Slots

Setscrew

Socket-head

Screws (x4)

1

Take note of the old tool flange position and orientation on the quill.

2 Loosen the setscrew and socket-head screws while holding the old tool flange in place. This

prevents it from falling off the z-axis quill.

3 Slide the tool flange off the z-axis quill.

4 Align the setscrew with the proper groove in the z-axis quill.

5 When the orientation is correct, slide the new tool flange up on the z-axis quill until it stops.

6 Apply thread lock (Loctite 243 or equivalent) to the setscrew and tighten to a torque of 1.1 N-m.

Precautions for Correct Use

Do not over-tighten the tool flange setscrew. This will cause off-center alignment of the

tool flange on the quill.

7

Apply thread lock (Loctite 222MS or equivalent) to the socket-head screws and then use a tor-

que wrench to tighten one of the socket-head screws to 1 N-m. Then, apply the same torque to

the other socket-head screws. Finally, tighten each socket-head screw to the full 2.5 N-m tor-

que.

8 When all socket-head screws are tight and the new tool flange is verified to be in the correct

orientation, the replacement procedure is complete.

6 Maintenance

6-10

i4L Robots User's Manual (I658)