Operating Instructions Chapter 7

DME4000

8014584/ZN33/2017-07 © SICK AG • Germany • Subject to change without notice 103

7 Maintenance

The DME4000 does not require any maintenance.

We recommend that you (at regular intervals):

Clean the optical lens surfaces

Check the screw and plug connections

8 Troubleshooting and Explanation of Terms

8.1 Troubleshooting

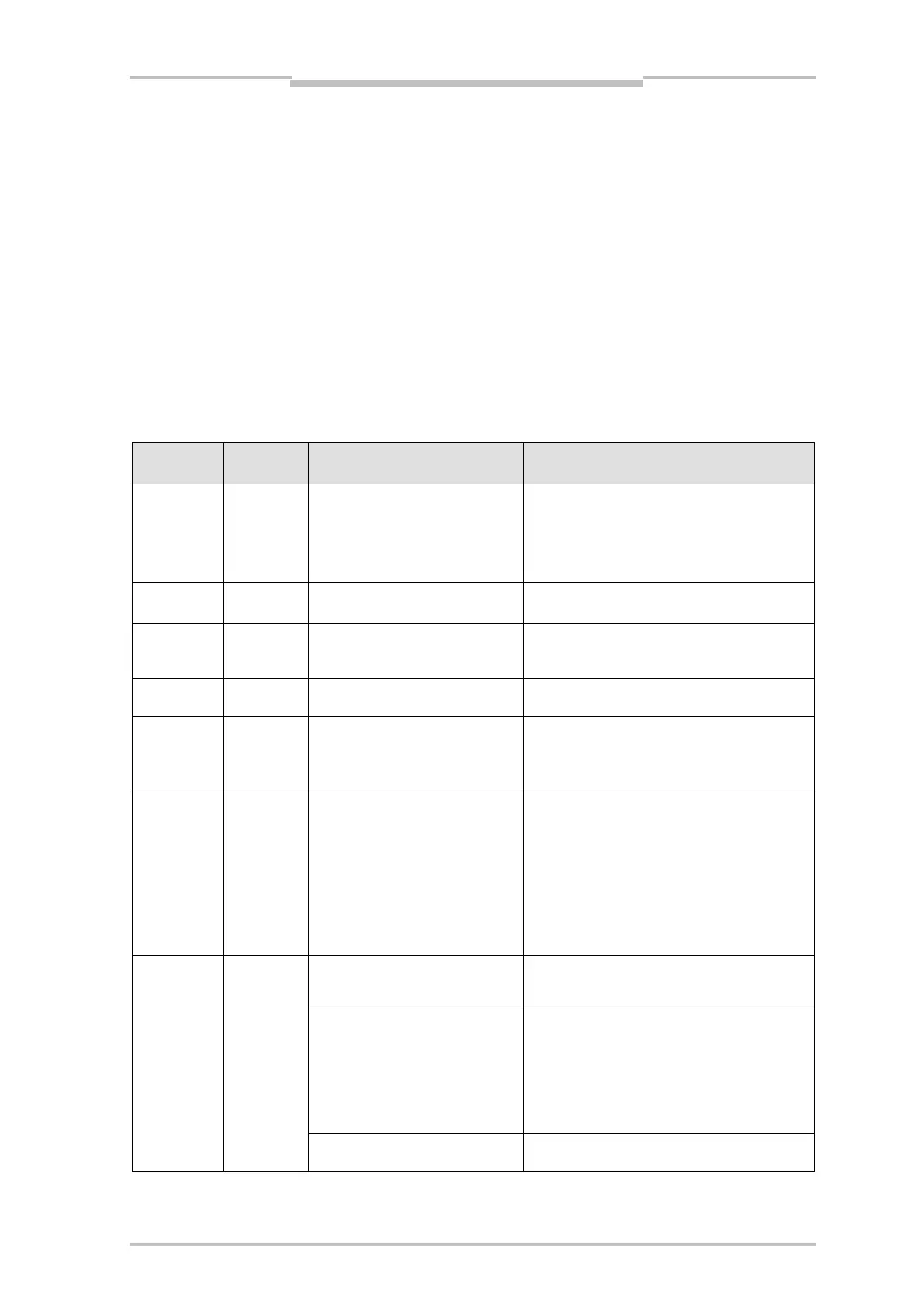

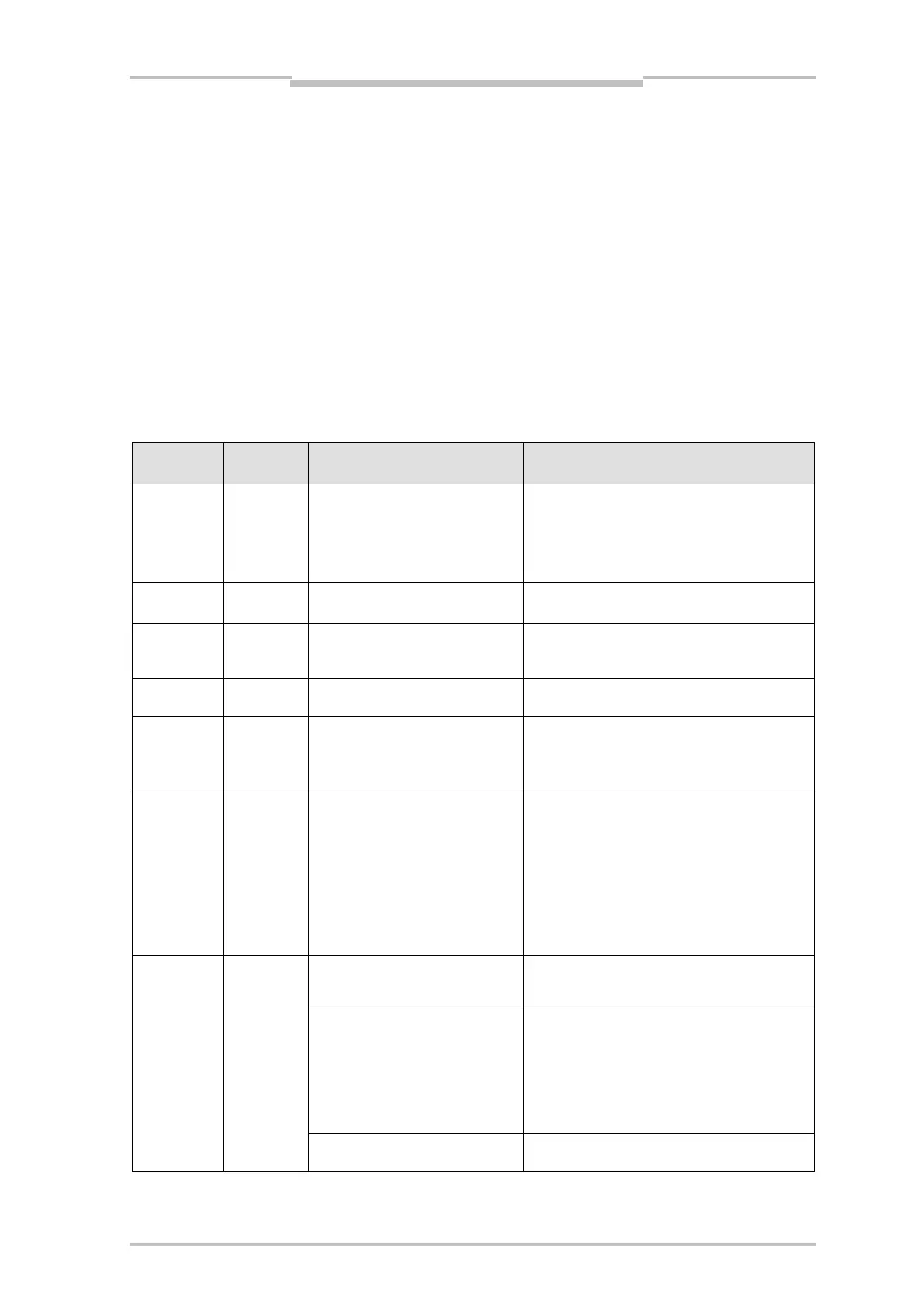

BUS indicator

RS 422: request mode

PROFIBUS/DeviceNet: no data flow

CANopen: no data flow

check clock-pulse generator

RS 422: continuous mode

PROFIBUS/DeviceNet: check wiring and shielding

CANopen: (pre-)operational mode or check wiring

indicator

Pre-failure message for measurement

laser

The measurement laser is still ready for operation,

but it is at the end of its operating life;

have replace sensor ready

Pre-failure message: Attenuation

The measured values are still OK; clean the optical

surfaces (reflector, lens)

Internal sensor temperature at fringe

range

Check ambient temperature; if necessary, improve

ventilation. Protect against radiating heat, e.g.,

provide shade against direct sunlight. Use the

sensor with heating when the temperature is low

Light path to reflector interrupted

With simultaneous ATT indicator: Lens

or reflector soiled

c)With simultaneous LSR indicator:

Laser defect

Observe light spot on the reflector; it may not move

away from the reflector. If necessary, realign or use a

larger reflector

Clean lens or reflector

c) Laser is defect; replace the sensor

(blinking

indicator)

Check supply voltage, voltage off/on, if not self-

repairing; Contact the service department

Sensor temperature not within

specifications

(internal temperature < –15 °C: Wait until warm-up

phase finishes. It might be necessary to use the

sensor with heating

Sensor too warm

(internal temperature > 80 °C:

Let sensor cool down

Effect: Measured value output is set to

zero

Loading...

Loading...