5 Measuring Cycles for Milling Machines and Machining Centres 08.96

5.2 L977 Workpiece measurement hole/shaft/slots/ZO determination (paraxial)

5.2 L977 Workpiece measurement hole/shaft/slots/ZO

determination (paraxial)

The cycle determines the dimensions of holes, shafts and slots (H-S-S measuring cycle) and

performs automatic tool offset when necessary.

It also determines the zero offset (ZO) between the centre point of a hole, shaft or slot and the

workpiece zero point.

For measuring variants hole and shaft, measurements can be performed with active coordinate

rotation (see MDC 7004.1).

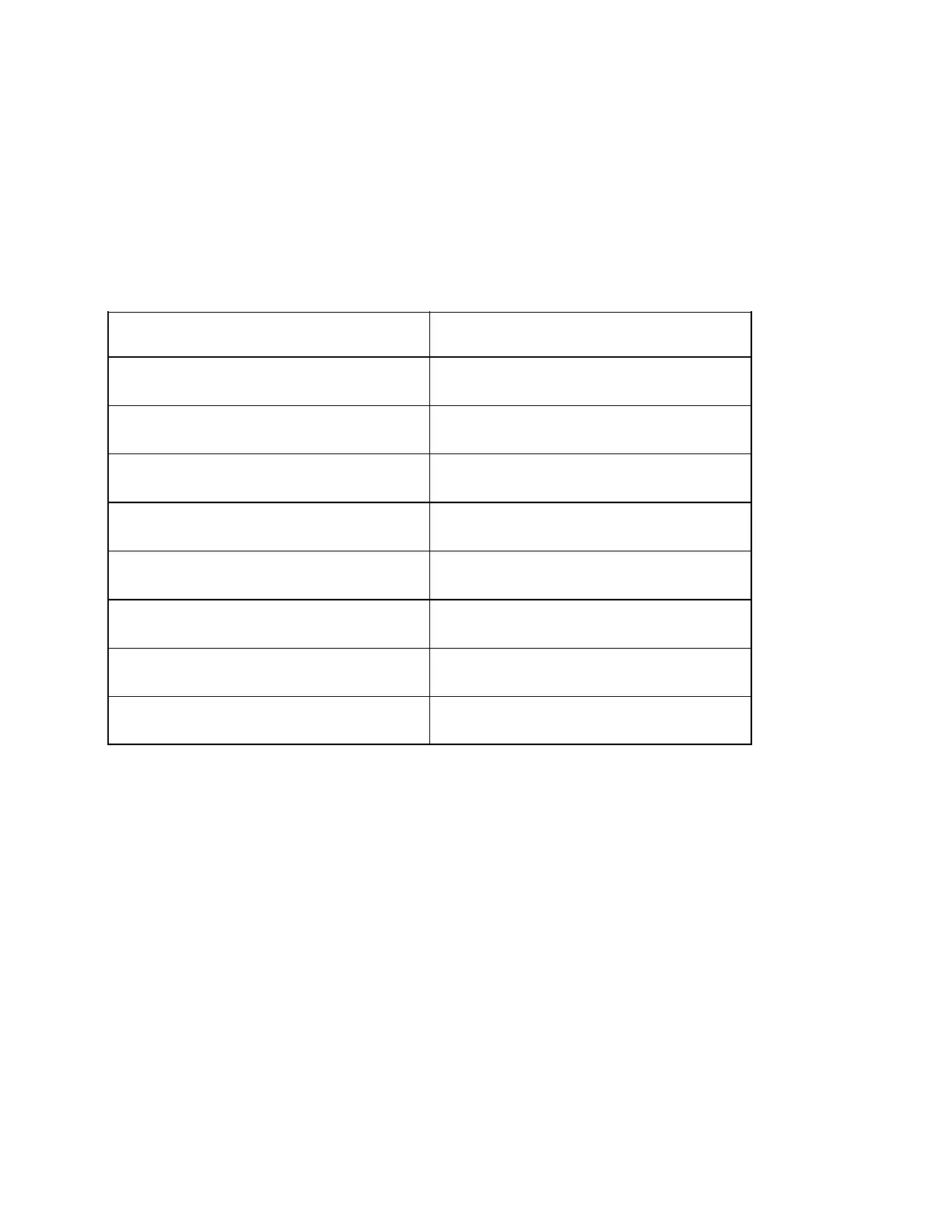

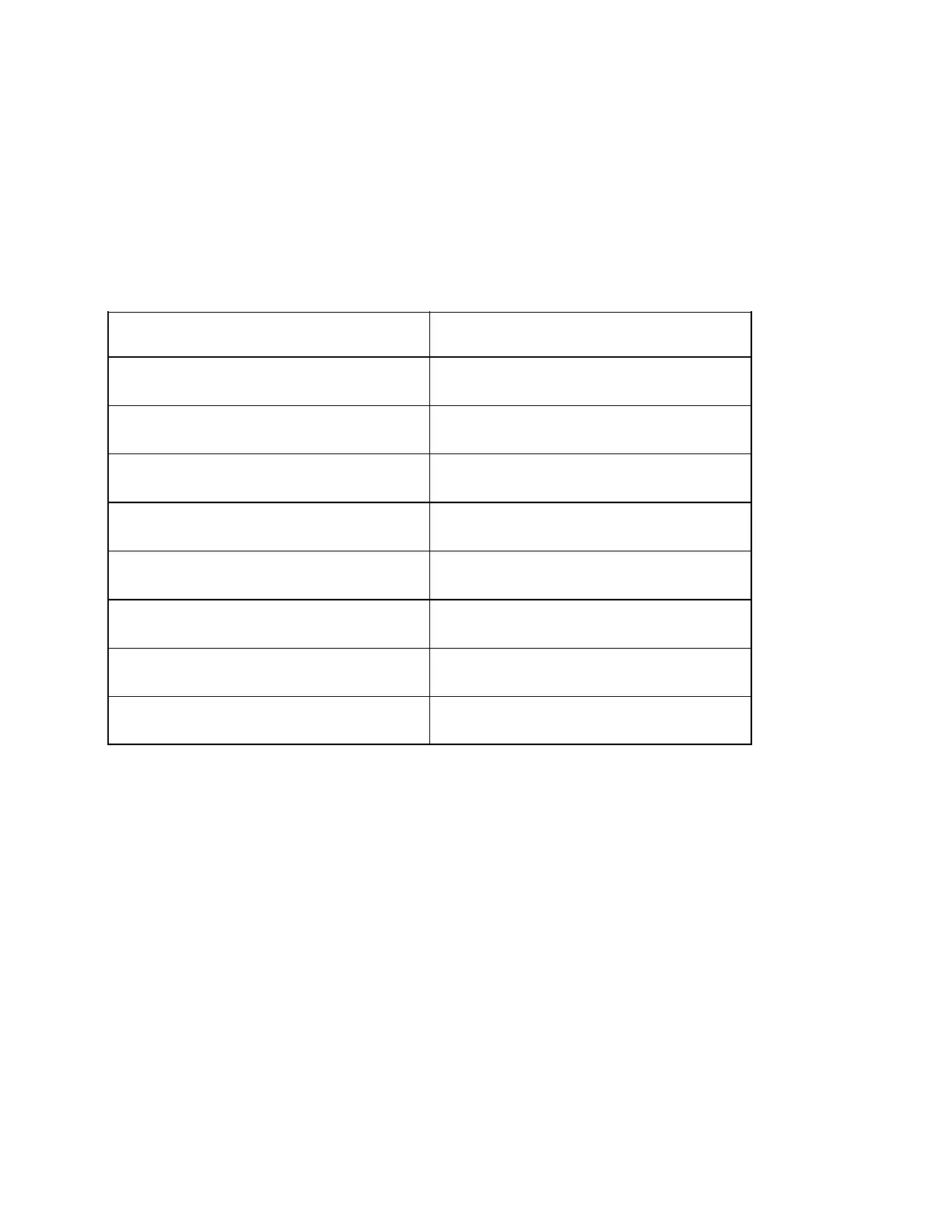

Selection is performed on the basis of the definition of R23:

Definition of R23 Prepositioning

R23= 1 Measure hole with

tool offset

C. p., applicate for depth

R23= 2 Measure shaft with

tool offset

C. p., applicate approx. 1 mm above shaft

R23= 11 Measure slot with

tool offset

C. p., applicate for depth

R23= 12 Measure web with

tool offset

C. p., applicate approx. 1 mm above web

R23= 21 ZO determination in hole with

correction of the zero offset

C. p., applicate for depth

R23= 22 ZO determination at shaft with

correction of the zero offset

C. p., applicate approx. 1 mm above shaft

R23= 31 ZO determination in slot with

correction of the zero offset

C. p., applicate for depth

R23= 32 ZO determination at web with

correction of the zero offset

C. p., applicate approx. 1 mm above web

Applicable types of probe: (see Section 1.3)

• In the case of milling and machining centres the probe must be entered as type 30 in the

TOA memory.

•

Multidirectional probe

•

Monodirectional probe

•

Bidirectional probe

A distinction is made between the probe types by defining R22 (see Section 2.6).

5–14 ©

Siemens AG 1990 All Rights Reserved 6FC5197- AB70

SINUMERIK 840/850/880 (BN)

Loading...

Loading...