08.96 4 Measuring Cycles for Turning Machines

4.2.1 L973 Calibrating on any surface

4.2.1 L973 Calibrating on any surface

Function and application

This measuring cycle can be used to calibrate the probe at any surface, e.g. the workpiece. As

from Version 3.5 the function "Mirroring" can also be active in the axes concerned.

After calibration has been completed, the probe is at a distance ”a” facing the calibration

surface.

Preconditions :

• The probe is called with tool offset and without G53 to face the calibration surface.

• When calibrating in a hole (groove/slot) the probe must be prepositioned to the centre

point.

• When calibrating beneath the turning centre in plus-X direction or left of the workpiece

zero

point W in plus-Z direction, the setpoint (R32) must be specified as a negative value.

• When calibrating in a random hole (groove/slot) the probe must be prepositioned to the

centre point.

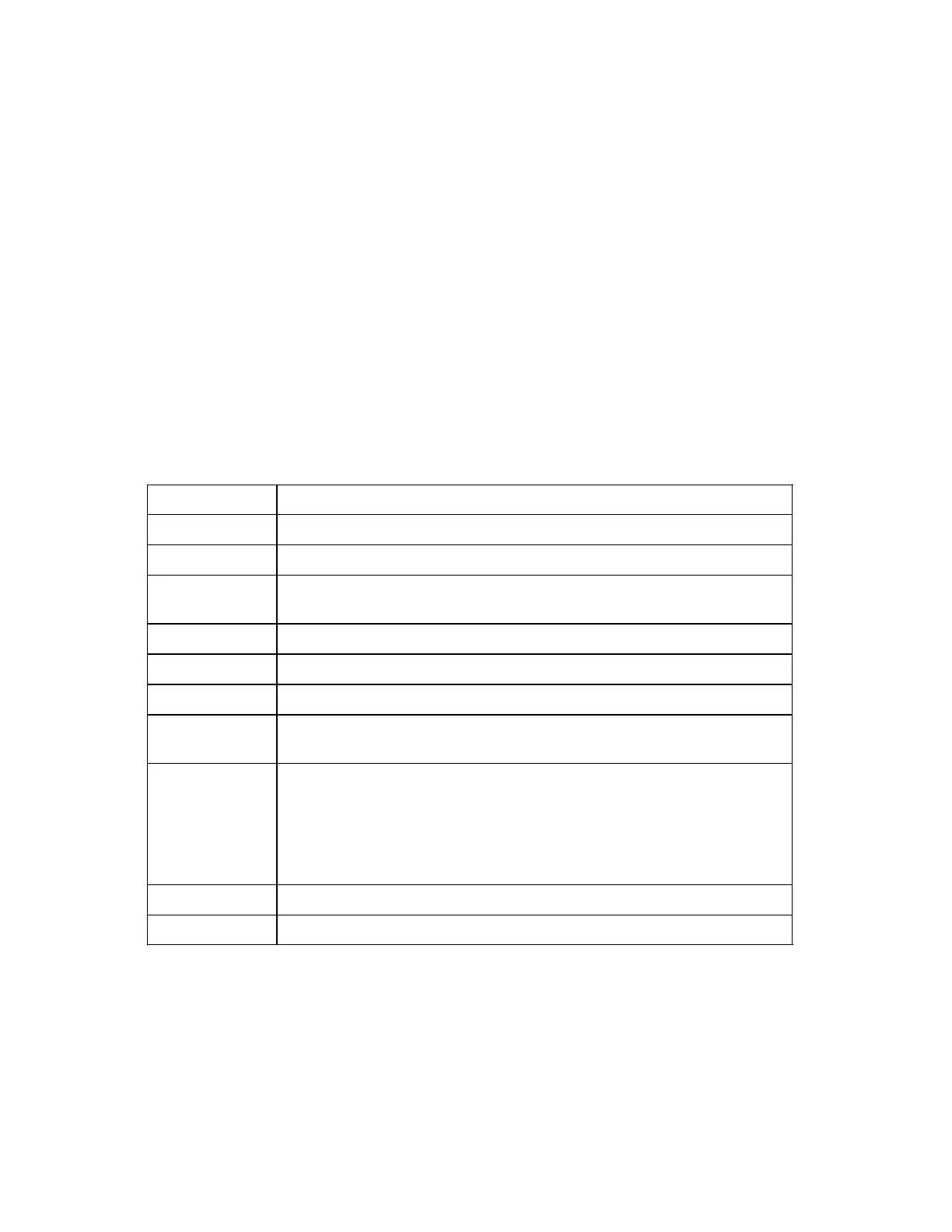

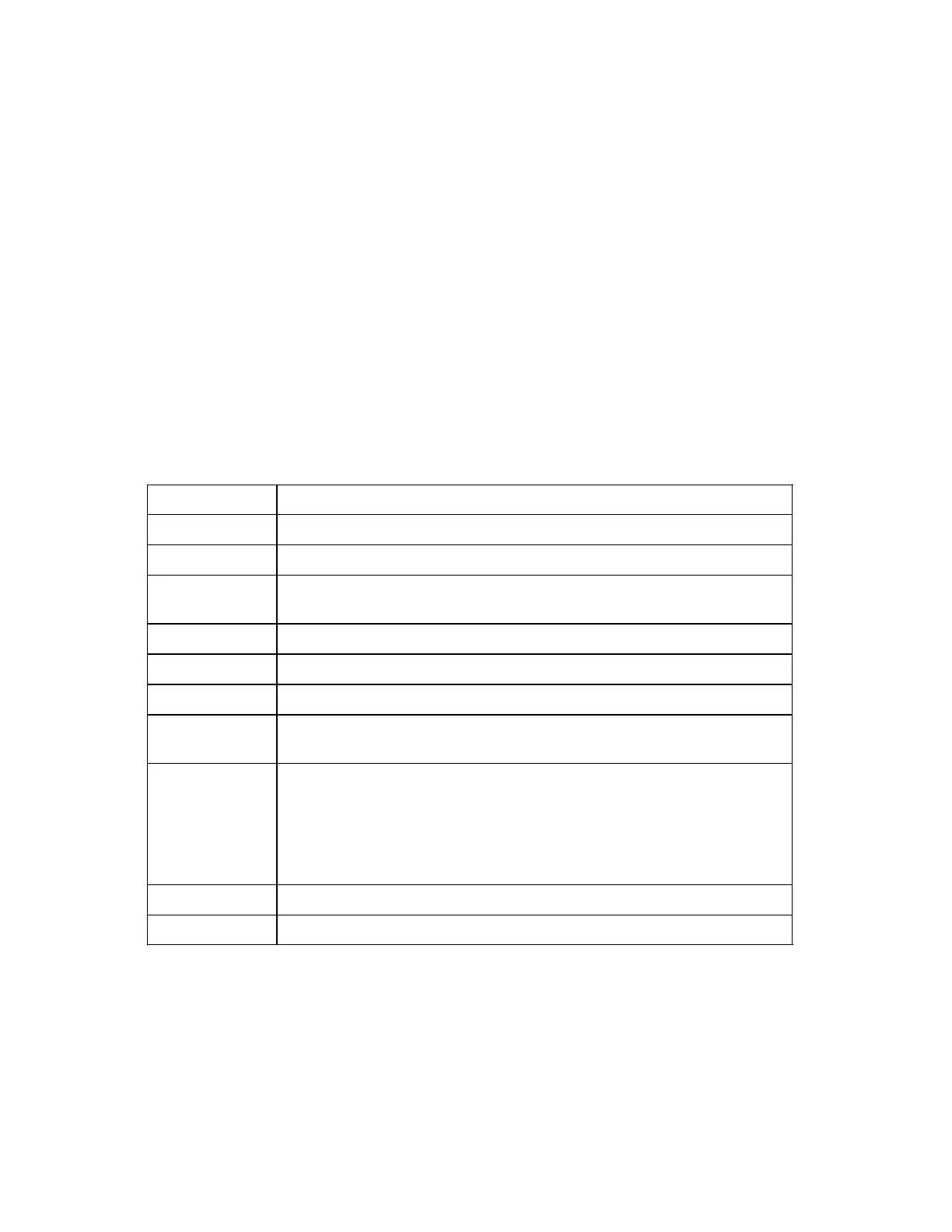

The following parameters must be defined prior to call:

Parameters Description

R22 Workpiece probe number

R23 = 22 Calibrating the workpiece probe on any surface (see Section 2.7.2)

R25

R25 = 0

Variable measuring speed in mm/min

Standard cycle value

R27 = 1...R

max

Number of measurements at same location (typically 1..3)

R28 = 1...R

max

Multiplication factor for measurement path ”2a”

R30 = 1...3 Number of measuring axis

R31 = 0

R31 = 1

Positive axis direction

Negative axis direction

R32 Setpoint referred to workpiece zero point, for transverse axis in the dia-

meter. When calibrating beneath the turning centre in plus-X direction or

left of the workpiece zero point in plus-Z direction, the setpoint must be

specified as a negative value. Where the measurement variant is any

hole, R32 means diameter of hole, the approach position is the centre

point.

R33 Zero offset range

R36 Safe area

© Siemens AG 1990 All Rights Reserved 6FC5197- AB70 4–21

SINUMERIK 840/850/880 (BN)

Loading...

Loading...