08.96 5 Measuring Cycles for Milling Machines and Machining Centres

5.4.1 L978 ZO determination on surface (1-point measuring cycle)

5.4.1 L978 ZO determination on surface (1-point measuring cycle)

Function and application

The measuring cycle determines the actual value of a blank relative to the machine zero point.

An empirical value stored in the MDC is subsequently allowed for with the correct sign.

The multiplication factor for measurement path ”2a” makes it possible to take into account the

variation range of the blanks (set value).

The probe faces the measuring surface at a distance of ”a” on completion of measurement.

No automatic ZO entry is carried out or alternatively additive input of the measuring axis

difference is performed in the ZO memory specified, depending on the definition of R10.

Preconditions:

The probe must be positioned with tool offset and without G53 to face the surface to be

measured.

The following parameters must be defined prior to call:

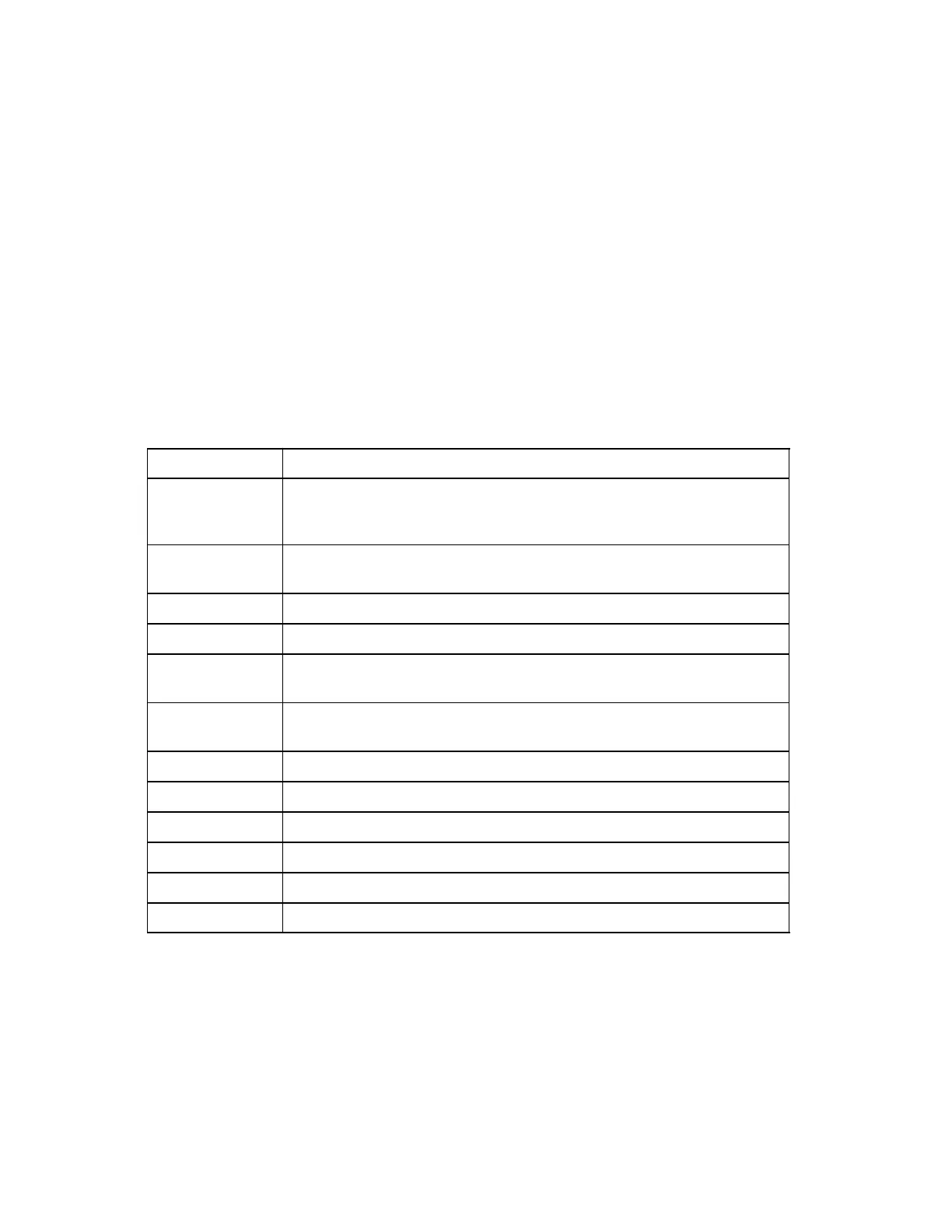

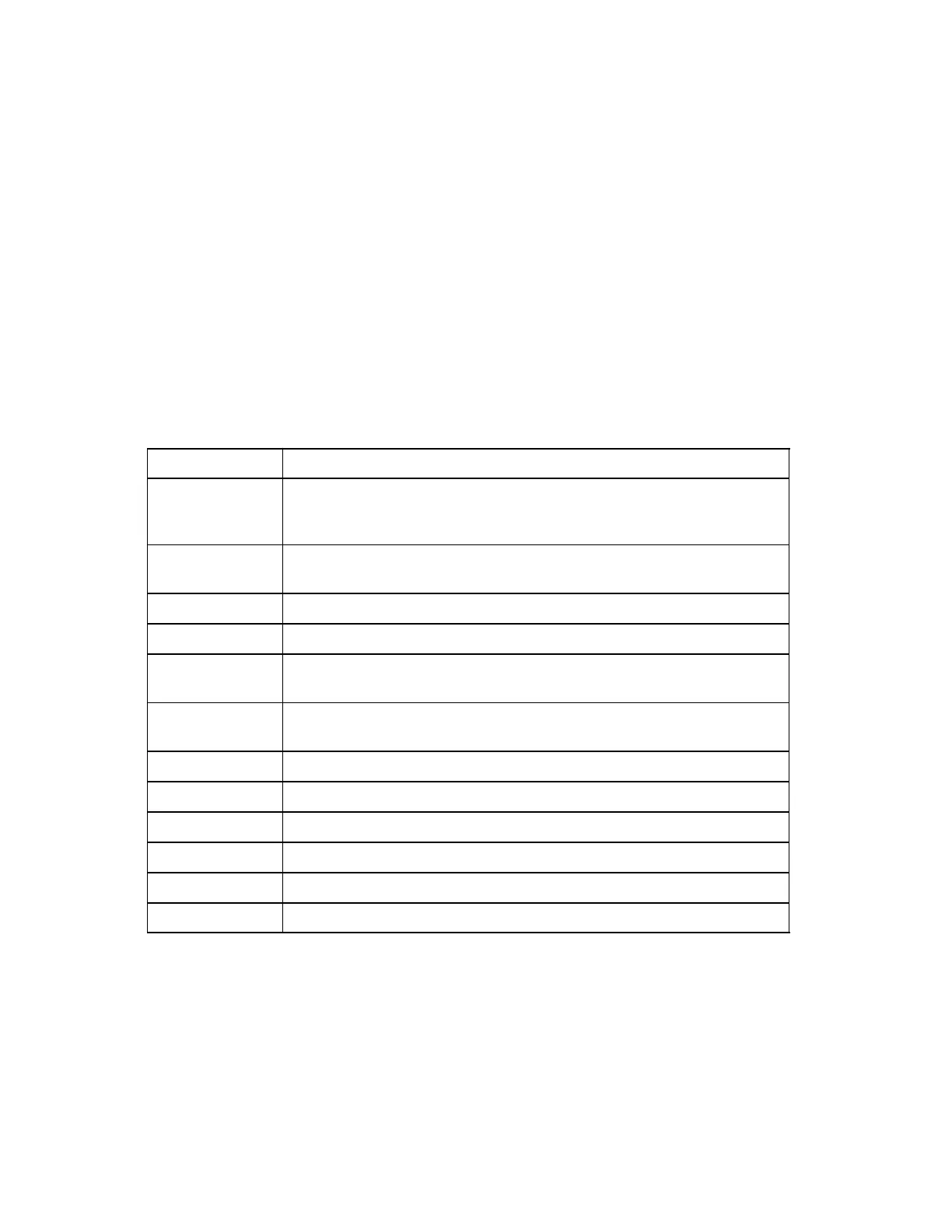

Parameters Description

R10 = 0

= 1...4

= 5

No automatic ZO entry

Automatic ZO entry in ZO G54...G57

Automatic ZO entry in ZO G58

R11 = 0

> 0

Without empirical value

Empirical value memory number (see Section 2.3)

R13 = 0...359.5 Compensation angle position for monodirectional probe (see

Section 2.5)

R22 Probe number (see Section 2.6)

R23 = 0

= 10

ZO determination at surface

ZO determination at surface with differential measurement

R25

R25 = 0

Variable measuring speed in mm/min

Standard cycle value

R26 = 0...359.5 Start angle (with differential measurement only)

R27 = 1...R

max

Number of measurements at same location (typically 1..3)

R28 = 1...R

max

Multiplication factor for measurement path ”2a”

R30 = 1...3 Number of measuring axis (see Section 2.12)

R32 Set value in relation to workpiece zero point

R36 Safe area

See Section 10.2 for result display parameters.

©

Siemens AG 1990 All Rights Reserved 6FC5197- AB70 5–67

SINUMERIK 840/850/880 (BN)

Loading...

Loading...