5-33

5-2. MECHANISM SECTION

ADJUSTMENT

For details of mechanism section adjustments, checks, and

replacement of mechanism parts, refer to the separate volume “DV

MECHANICAL ADJUSTMENT MANUAL C Mechanism ”.

2-1. OPERATING WITHOUT CASSETTE

1) Refer to “2. Removal” and supply the power with the cabinet

assembly removed.

2) Connect the adjustment remote commander to the LANC jack.

3) Turn on the HOLD switch of the adjustment remote

commander.

4) Close the cassette compartment without the cassette.

5) Select page: 0, address: 01, and set data: 01.

6) Select page: C, address: 52, and set data: FD, and press the

PAUSE button of the adjustment remote commander.

7) Select page: D, address: 10, and set data: 10, and press the

PAUSE button of the adjustment remote commander.

8) Turn off the HOLD switch of the adjustment remote

commander.

9) Turn the power off and then on.

The above procedure enables the mechanism to operate without the

cassette. After checking operations be sure to perform “Procedure

After Checking Operations”. To use the “No-Cassette Operation

Mode” and “Forced Power ON Mode” together, set the following

data to page: D, address: 10.

Forced VTR power ON mode ............................................. 12

Forced Camera power ON mode ........................................ 11

[Procedure after checking operations]

1) Select page: 0, address: 01, and set data: 01.

2) Select page: C, address: 52, and set data: FF, and press the

PAUSE button of the adjustment remote commander.

3) Select page: D, address: 10, and set data: 00, and press the

PAUSE button.

4) Select page: 0, address: 01, and set data: 00.

5) Disconnect the power supply of the unit.

2-2. TAPE PATH ADJUSTMENT

1. Preparations for Adjustment

1) Clean the tape running side (tape guide, capstan shaft, pinch

roller).

2) Connect the adjustment remote commander to the LANC jack.

3) Turn on the HOLD switch of the adjustment remote

commander.

4) Select page: 3, address: 3C, and set data: 07.

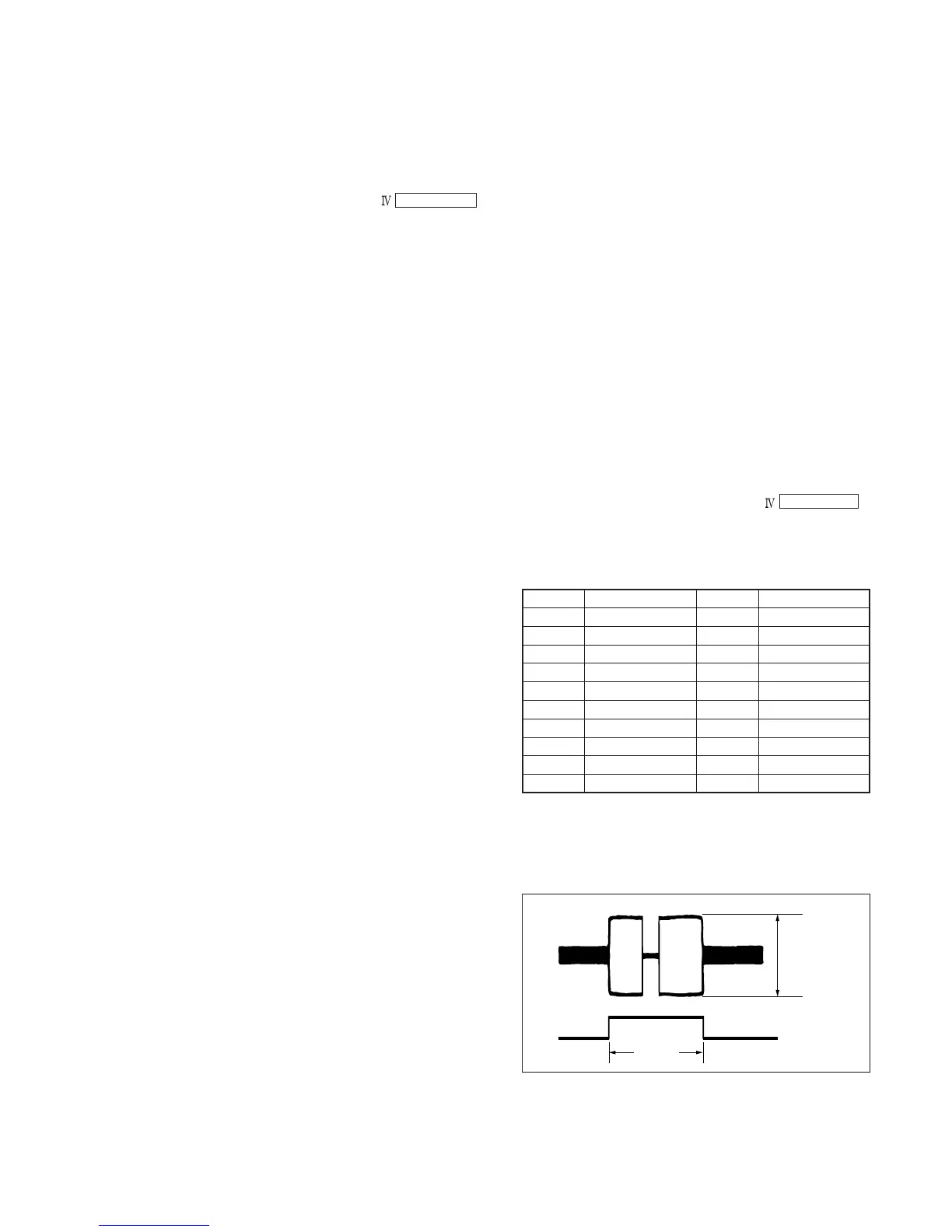

5) Connect the oscilloscope.

Channel 1: VC-206 board, CN9903 Pin 8 (Note)

External trigger: VC-206 board, CN9903 Pin 6

(Connect the oscilloscope via CPC-8 jig (J-6082- 388-A)

6) Playback an alignment tape (XH2-1) for tracking.

7) Check that the oscilloscope RF waveform is flat at the entrance

and exit.

If not flat, adjust according to the separate volume “DV

MECHANICAL ADJUSTMENT MANUAL

C Mechanism ”.

8) After completing the adjustment, perform “2. Procedure after

checking operations”.

Note: Connect Pins 8 and 4 (GND) of CN9903 with a 75Ω resistor.

CN9903 of VC-206 board

[Procedure after operations]

1) Connect the adjustment remote commander, and turn on the

HOLD switch.

2) Select page: 3, address: 3C, and set data: 00.

3) Disconnect the power supply of the unit.

Fig. 5-2-1.

Pin No.

1

3

5

7

9

11

13

15

17

19

Signal Name

TCK

TDI

AFC ERR

IR FSC

VCC2

VCC1

LOCK

ENV OUT

TDO8

DEC B-Y

Pin No.

2

4

6

8

10

12

14

16

18

20

Signal Name

TMS

GND

JSWP

RF MONITOR

AGC IN

EQ IN

EVF BL 4.75V

EVF 4.75V (–)

VCO

EVF VG

CH1

CH2

(Trigger)

Must be fla

Loading...

Loading...