2·16

PERIODIC

MAINTENANCE

CYLINDER COMPRESSION

NOTE:

Figures shown are guidelines only, not absolute service limits.

Cylinder

compression:

960-1

400 kPa (9.6

-14.0

kg/cm

2

,

137-199

psi)

Low compression pressure can indicate one or more of the fol-

lowing:

•

Excessively worn cylinder wall

•

Worn piston or piston rings

• Stuck piston rings

• Poor seating of valves

•

Ruptured or otherwise damaged cylinder head gasket

Test procedure

i.

Start and warm

up

the engine, then shut the engine off.

2.

Remove the spark plug.

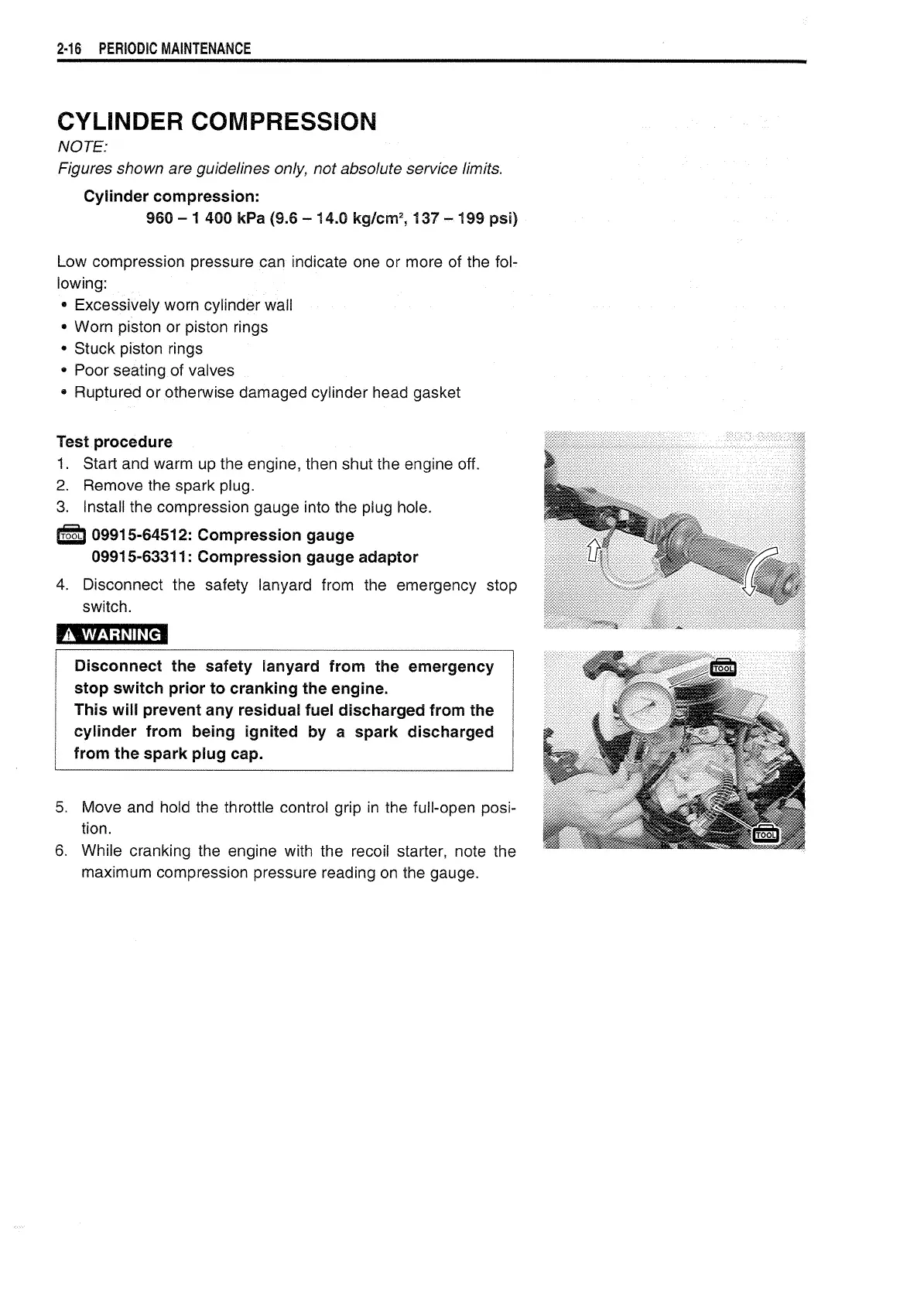

3.

Install the compression gauge into the plug hole.

IMOh

09915-64512: Compression gauge

09915-63311:

Compression

gauge

adaptor

4.

Disconnect the safety lanyard from the emergency stop

switch.

A WARNING

Disconnect

the safety lanyard

from

the emergency

stop

switch

prior

to

cranking

the engine.

This

will prevent any residual fuel discharged from the

cylinder

from

being ignited

by

a

spark

discharged

from

the

spark

plug

cap.

5.

Move and hold the throttle control grip

in

the full-open posi-

tion.

6.

While cranking the engine with the recoil starter, note the

maximum compression pressure reading

on

the gauge.

Loading...

Loading...