7. Cylinder Head / Valve

To this chapter contents

Valve Clearance Adjustment

7-17

Caution

z Inspect and adjust the valve clearance

when the engine is cool (under 35°C).

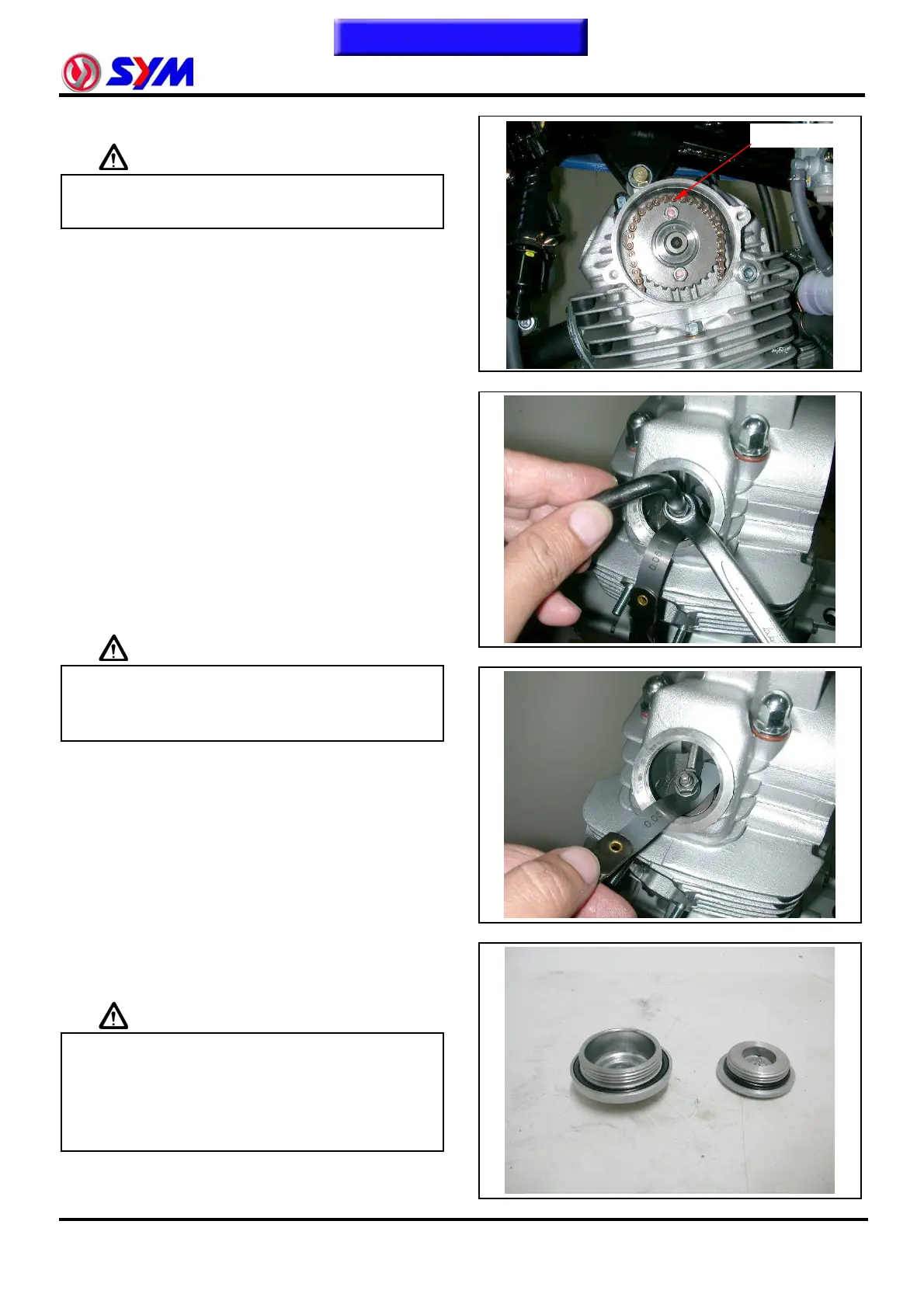

Remove the tappet adjusting hole cap.

Remove the cylinder head side cover.

Use a T type wrench to rotate the crankshaft

clockwise and align the “T” mark on the

flywheel with the index mark on the left

crankcase cover and the timing mark on the

sprocket with the index mark on the cylinder

head (piston is at top dead center on the

compression stroke).

Valve clearance inspection / adjustment

Inspect and adjust valve clearance with

thickness gauge.

Valve clearance:IN 0.05±0.02 mm

EX 0.05±0.02 mm

Loosen the fixing nut and rotate the adjusting

bolt to adjust valve clearance.

Fasten the adjusting bolt and tighten the fixing

nut when the standard value is reached.

Caution

z Confirm the valve clearance reach the

standard value when the fixing nut is

tightened.

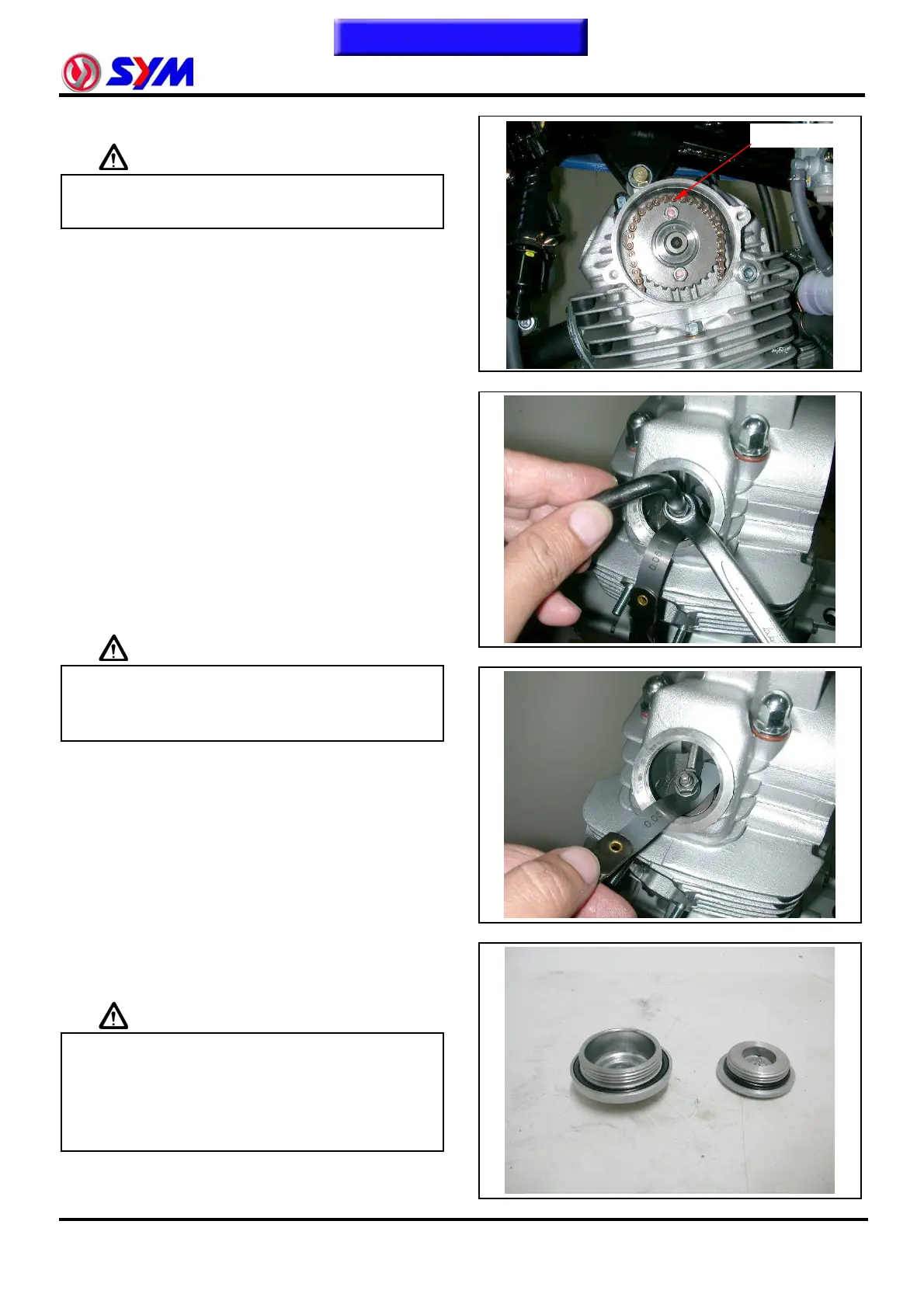

Install the tappet adjusting hole cap, cylinder

head side cover, timing inspecting hole cap

and ACG cap.

Caution

z Check for any damage on the O ring and

coat it with engine oil before installing the

tappet adjusting hole cap, cylinder head

side cover, timing inspecting hole cap and

ACG cap.

TDC mark

Loading...

Loading...