5-28

MAINTENANCE

EVERY 50 HOURS

EVERY 50 HOURS

INSPECTING AND ADJUSTING THE

CRAWLER TENSION

• If you must work beneath the raised

machine or working equipment, always

use wood blocks, jack-stands or other

rigid and stable supports. Never get

under the machine or working

equipment if they are not sufficiently

supported. This procedure is especially

important when working on hydraulic

cylinders.

• Be careful with the high-pressure grease

In the track adjuster, the grease has

been injected under high pressure. If the

tension is adjusted without following the

prescribed procedure, the grease

discharge valve may fly off, resulting in

injury.

· Never loosen the grease fitting.

· Loosen the grease discharge valve

slowly. Do not turn it more than one

turn.

· Do not put your face, arms, legs or

body in front of the grease discharge

valve.

· If grease does not come out when the

grease discharge valve is loosened,

the valve is faulty. Ask a Takeuchi

service agent for repair.

Inspection

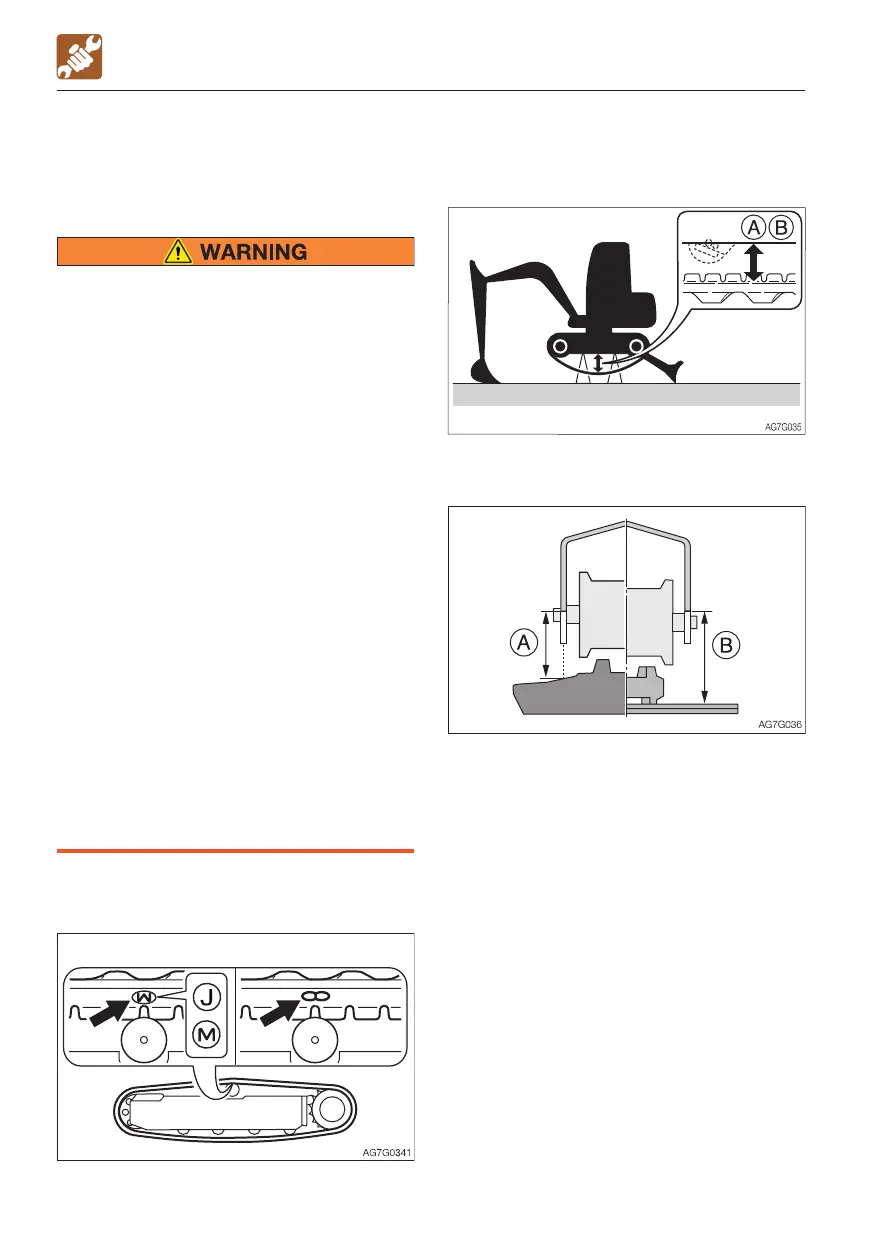

1. For rubber crawlers, move the machine so

that the “M”, “J” or “∞” mark at the joint is

at the top center of the crawler frame.

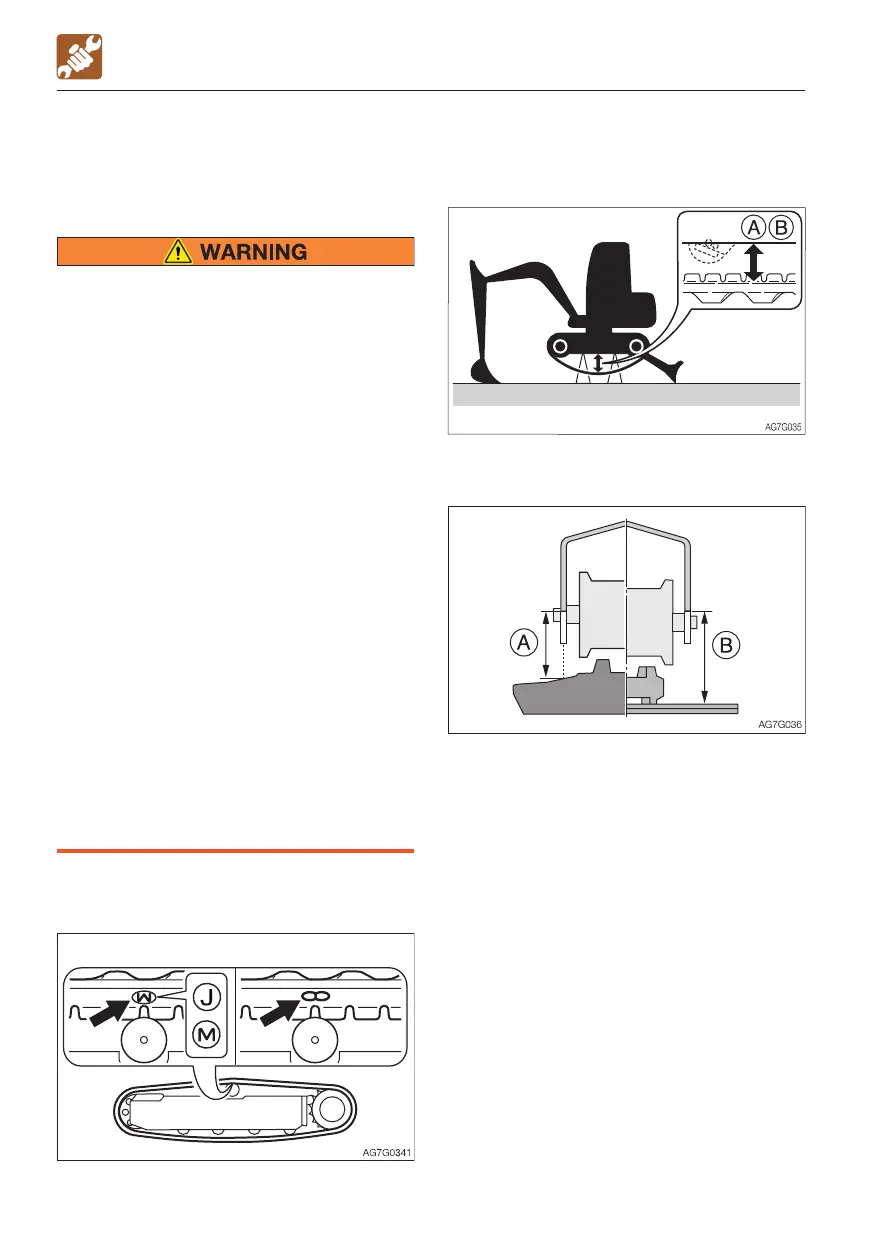

2. Use the working equipment to lift the

machine body. Operate the levers slowly.

3. Inspect the gap (A or B) between the

bottom surface of the frame at the center

of the crawler frame and the top surface of

the crawler.

The gap (A or B) must be within the

following range:

(A) Rubber crawler

83 to 93mm (3.3 to 3.7 in.)

(B) Steel crawler

150 to 170mm (5.9 to 6.7 in.)

(B) Segmental rubber crawler

150 to 170 mm (5.9 to 6.7 in.)

Loading...

Loading...