5-60

MAINTENANCE

ADJUSTING THE GAP BETWEEN THE

BUCKET AND ARM (IF EQUIPPED)

• Before performing maintenance or

repairs under the machine, lower all

working equipment to the ground or in

the lowermost position.

• To prevent unexpected movement,

securely block the working equipment

when adjusting the gap.

WHEN REQUIRED

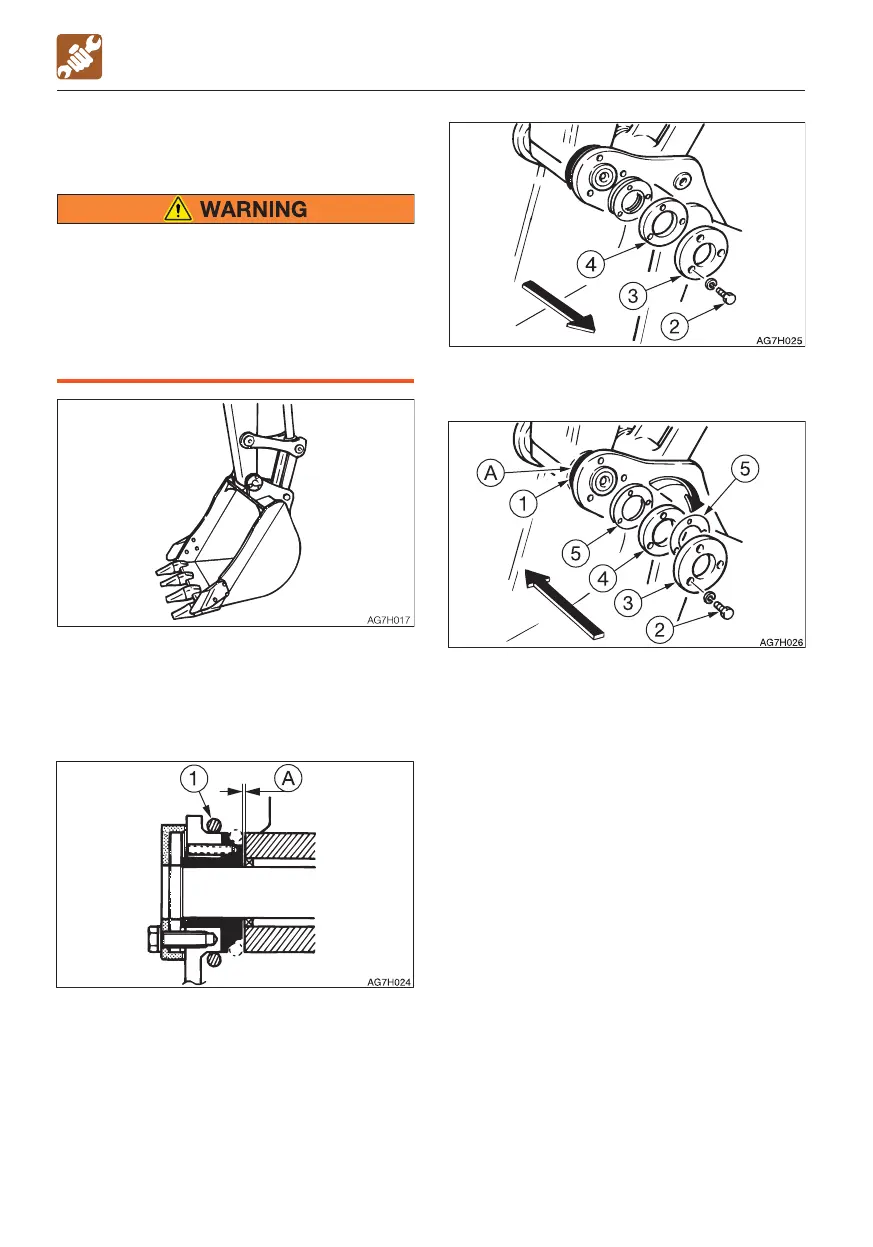

1. Lower the bucket to the ground as shown

on the figure above in a stable position.

2. Check that the bucket dose not move,

and then set the safety lock lever to the

locked position and stop the engine.

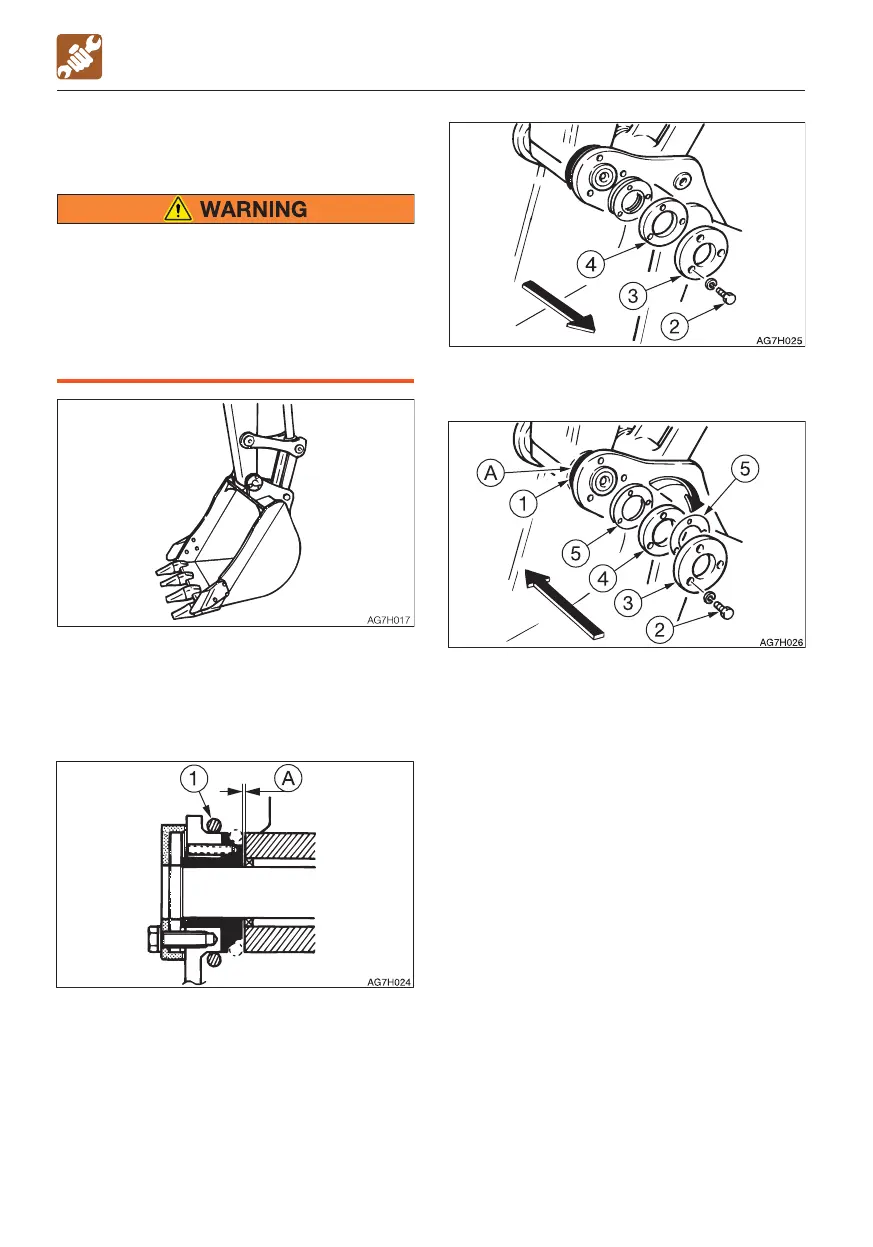

3. Move the O-ring (1) to bring the gap (A)

into view and measure the width of the

gap (A).

The gap (A) should be 0.5 mm (0.02 in.).

Swing the upperstructure slightly to the left

and lightly press the arm point to the left

side of the bucket (the side without an

adjuster).

4. Remove the three bolts (2), the end plate

(3) and flange (4).

5. Pull out the adjustment shim(s) (5)

corresponding to the gap (A) from

between the flange (4) and the bucket

body.

Adjustment shim thickness : 0.5 mm (0.02

in.)

Be careful that the gap is no less than 0.5

mm (0.02 in.) after adjustment.

Note:

Example (for a gap of 2 mm or 0.08 in.):

2 mm - 0.5 mm (standard value)= 1.5 mm

(0.06 in.)

In the above example, three shims (5) should

be removed.

6. Insert the adjustment shim(s) (5) removed

in step 5 above between the end plate (3)

and the flange (4), and then fasten it in

place with the three bolts (2).

· Tightening torque for bolts (2): 83 N·m

(61.5 ft-lb.)

7. Return the O-ring (1) to the original

position.

Loading...

Loading...