5-45

MAINTENANCE

REPLACING THE WATER SEPARATOR

FILTER

• Do not smoke or permit open flames

while handling fuel or working on the

fuel system.

• Stop the engine in a well-ventilated

place and allow it to cool down before

performing maintenance.

• Clean up spilled fuel immediately.

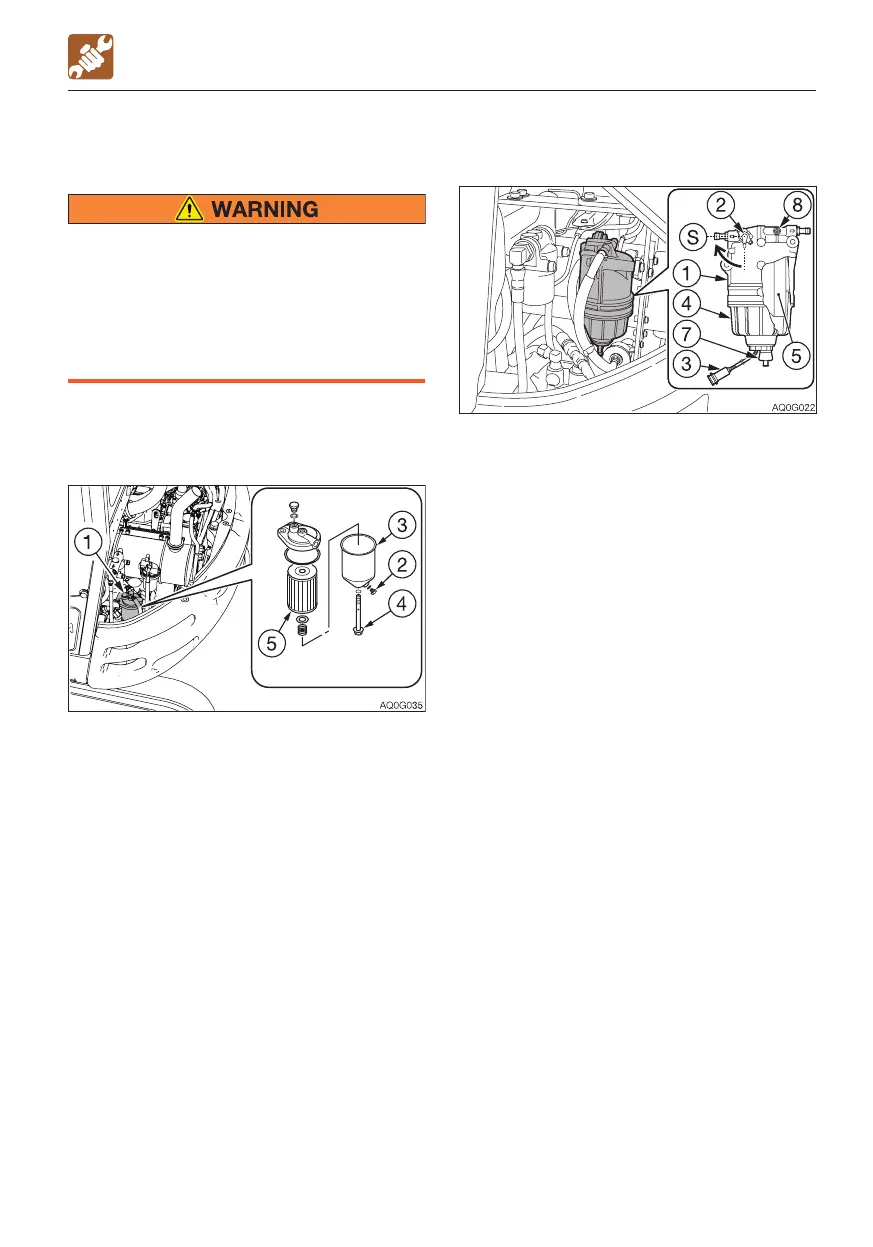

<Applicable machine models 126000002

or later>

If equipped with filter for high sulfur fuel

(S): Close

1. Open the engine hood.

2. Close the valve (2) of the water separator

(1).

3. Place a pan for catching fuel under the

drain hose.

4. Loose the air-bleeding plug (8) and the

drain plug (7) to discharge fuel from inside.

5. Remove the sensor wiring coupler (3).

6. Remove the case (4) with the filter wrench.

7. Remove the element (5), and then clean

the case. When doing the above, be

careful not to damage the sensor.

8. Replace the packing with a new one and

lubricate it with diesel fuel.

9. Install the new element (5) on the filter

stand.

10. Tighten the case (4) by hand. Be sure to

do it by hand.

Tightening torque: 27 to 33 N·m (20 to

24.6 ft-lb)

11. Install the sensor wiring coupler (3).

12. Tighten the drain plug (7).

13. Bleed air.

Refer to “Bleeding air from the fuel

system” on page 6-8.

EVERY 500 HOURS

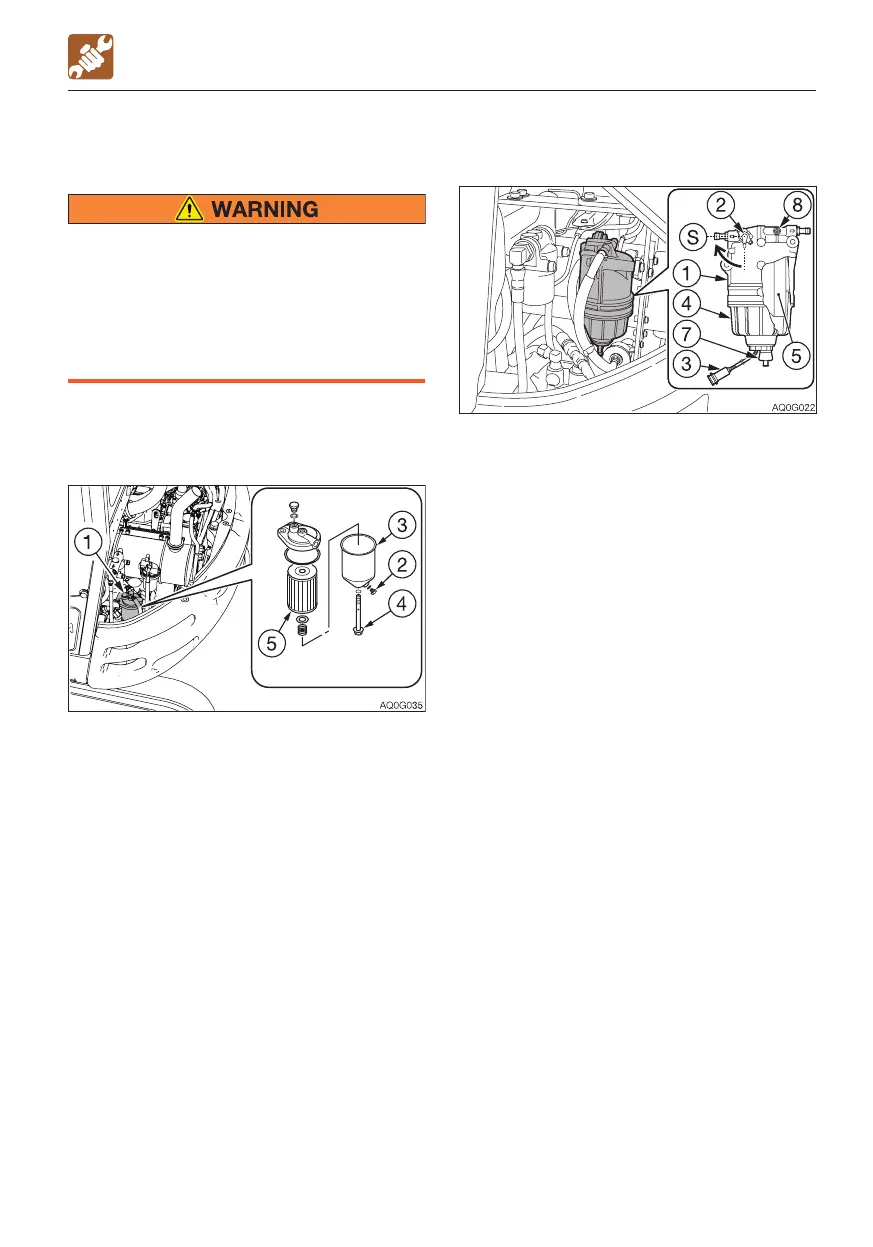

<Applicable machine models 126100003

or later>

1. Open the engine hood.

2. Place a pan under the filter (1).

3. Remove the plug (2) and drain the fuel

from the filter case (3).

4. loosen the bolt (4) right under the filter (1)

and remove the filter case (3).

5. Replace the element (5) in the filter case

(3) with a new one.

6. Install the filter case (3) and tighten the

bolt (4).

7. Tighten the plug (2) and bleed air.

Refer to “Bleeding air from the fuel

system” on page 6-8.

Loading...

Loading...