5-34

MAINTENANCE

AFTER THE INITIAL 250

HOURS (ONLY FOR NEW

MACHINES)

REPLACING THE HYDRAULIC OIL

RETURN FILTER

• Stop the engine and allow each part of

the machine to cool down before

performing maintenance.

· The engine, the hydraulic system and

many other parts of the machine are

hot immediately after the engine is

stopped. Touching these parts will

cause burns.

· The hydraulic oil is also hot and under

high pressure immediately after the

engine is stopped.

Be careful not to touch the oil when

loosening the cap or plug. Working on

the machine under these conditions

could result in burns or injuries due to

the hot oil spurting out.

• Oil may spurt out if caps or filters are

removed or pipes are disconnected

before releasing the pressure in the

hydraulic system.

· Press the air breather button to relieve

the internal pressure from the tank.

· When removing plugs or screws, or

when disconnecting hoses, stand to

the side and loosen them slowly to

gradually release the internal pressure

before removing.

AFTER THE INITIAL 250 HOURS (ONLY FOR NEW MACHINES)

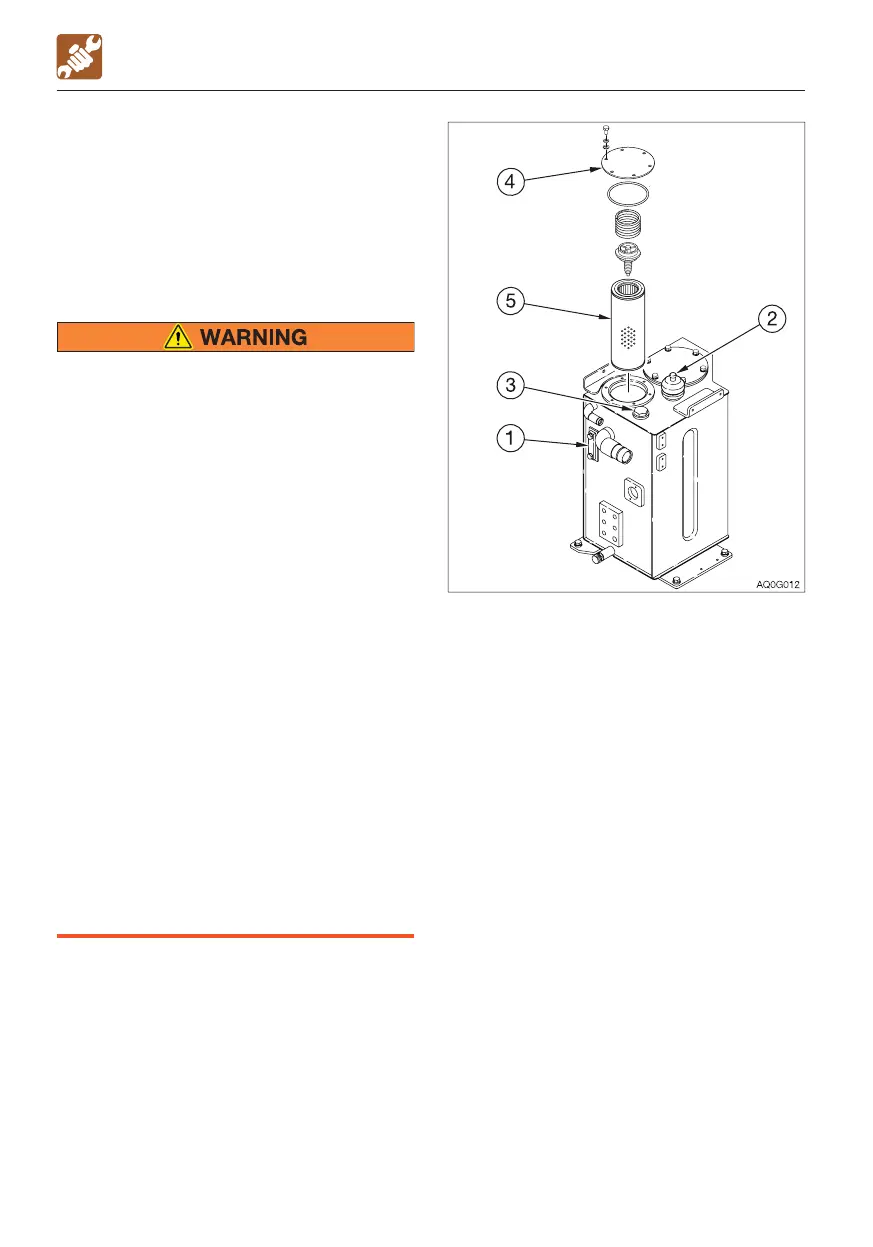

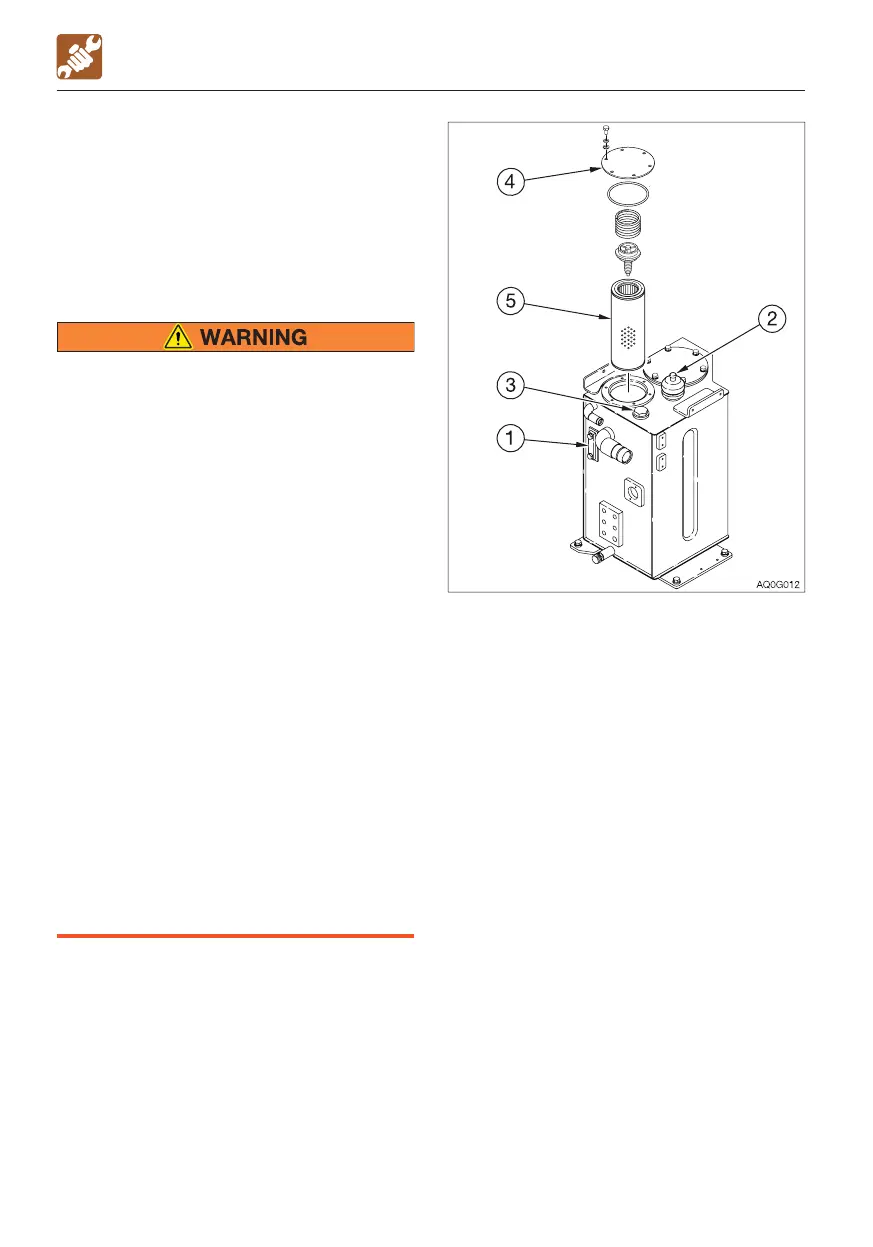

1. Open the right side cover.

2. Press the air breather button (2) to relieve

the internal pressure from the tank.

3. Loosen the bolts and remove the flange

(4).

4. Remove the return filter (5).

5. Install a new return filter.

6. Install the flange (4) on its original position.

7. Inspect the level with the sight gauge (1),

and replenish if the level is too low.

Refer to “Inspecting the hydraulic oil tank

level and replenishing” on page 5-22.

Loading...

Loading...