6-26

TROUBLESHOOTING

TOWING

When towing, serious injury or death

could result, if performed incorrectly or

the wire rope being used is inappropriate

or not properly inspected.

• It becomes dangerous if the wire rope

breaks or becomes disengaged. Use a

wire rope appropriate for the required

tractive force.

• Do not use a wire rope that is kinked,

twisted or otherwise damaged.

• Do not apply heavy loads abruptly to

the wire rope.

• Wear safety gloves when handling the

wire rope.

• Make sure there is an operator on the

machine being towed as well as on the

machine that is towing.

• Never tow on slopes.

• Do not let anyone come near to the wire

rope while towing.

IMPORTANT: Do not tow a machine if its

engine does not start or if the machine

does not run. Doing so could damage the

machine being towed.

IMPORTANT: Be sure to follow the steps

below closely when using the towing hole

to tow. Failure to heed even one of the

steps may cause damage to the towing

hole or other parts of the frame.

TOWING

Towing the machine

Use the procedure described below to tow

heavy objects or the machine itself if it

should get stuck in the mud and not be able

to get out on its own.

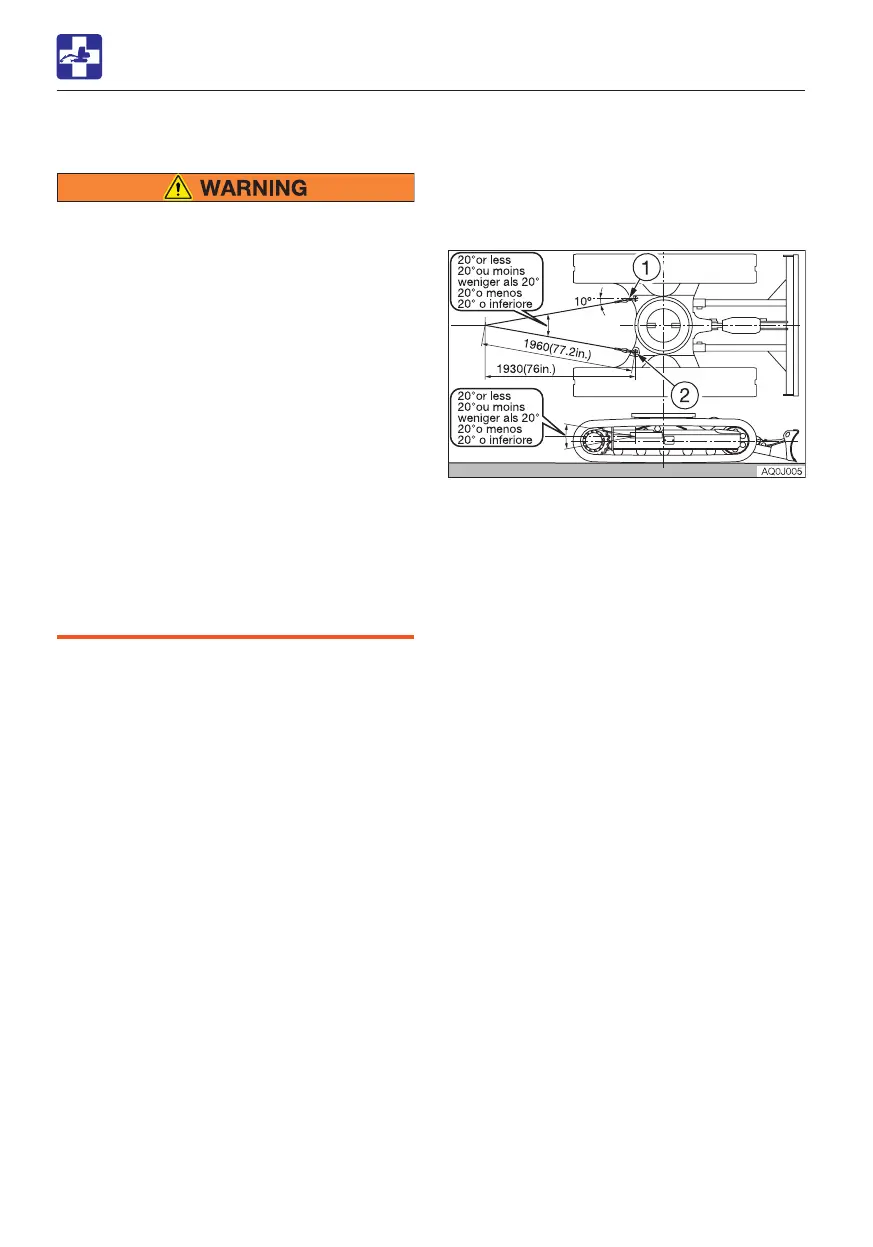

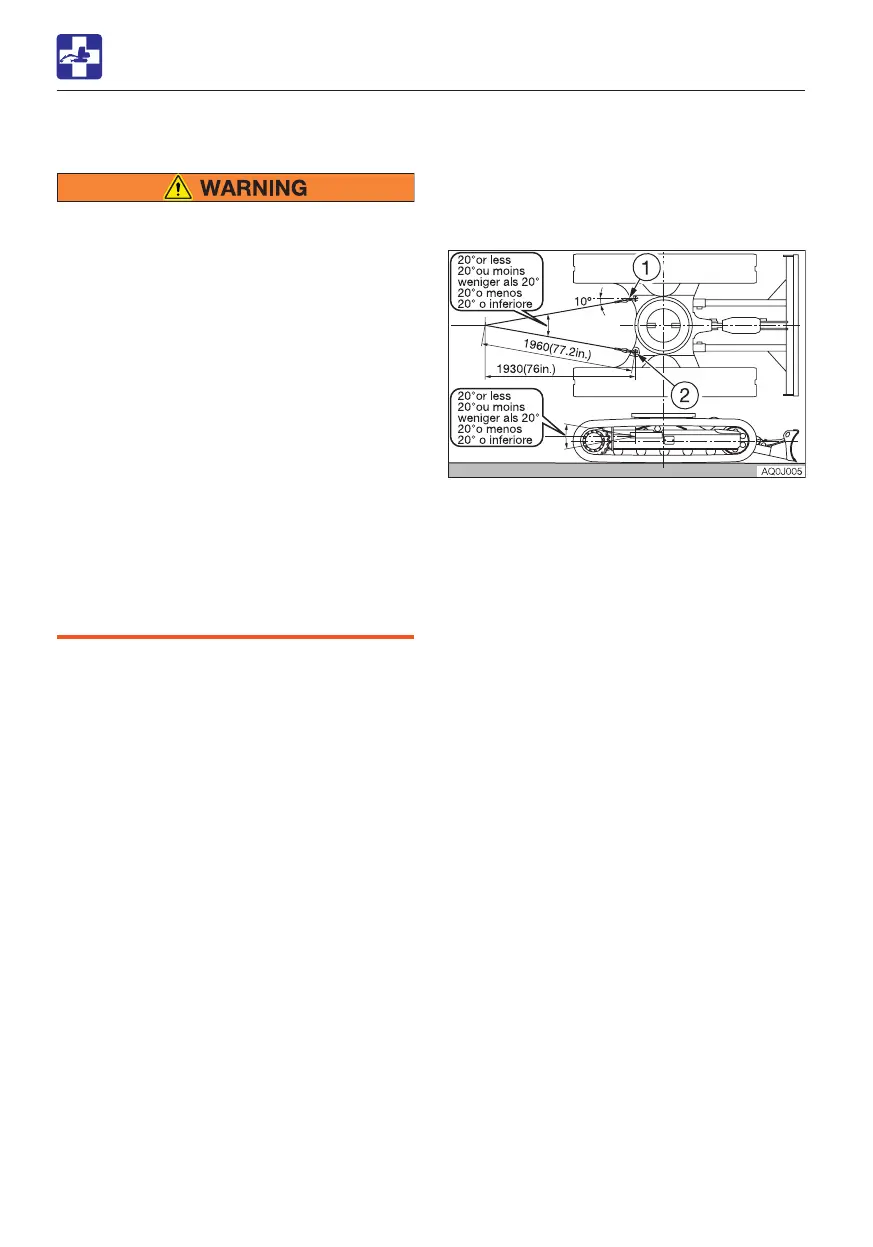

• Permissible forces: 83.2 kN (18700 lbf)

Do not tow using only a towing hole on one

side.

1. Attach the wire rope to the shackle (1).

2. Fasten the shackle (1) to the towing holes

(2).

3. Make sure that the wire rope is at a cone

angle of 20° or less to the travel frame.

4. Move the machine to tension the wire

rope.

5. Operate the machine slowly and tow.

Loading...

Loading...