3. DUCT TO SLEEVE CONNECTIONS

Dampers are supplied with sleeves and actuators from

the factory and can be installed without the need for

additional field installed sleeves.

Gauge of factory furnished sleeve determines the

type of duct to sleeve connections required (see table

below). Any duct connection other than the breakaway

connections described on page 7 are considered rigid.

Factoryfurnishedductcollars,typeRandO,arealso

considered breakaway (see Fig. 2).

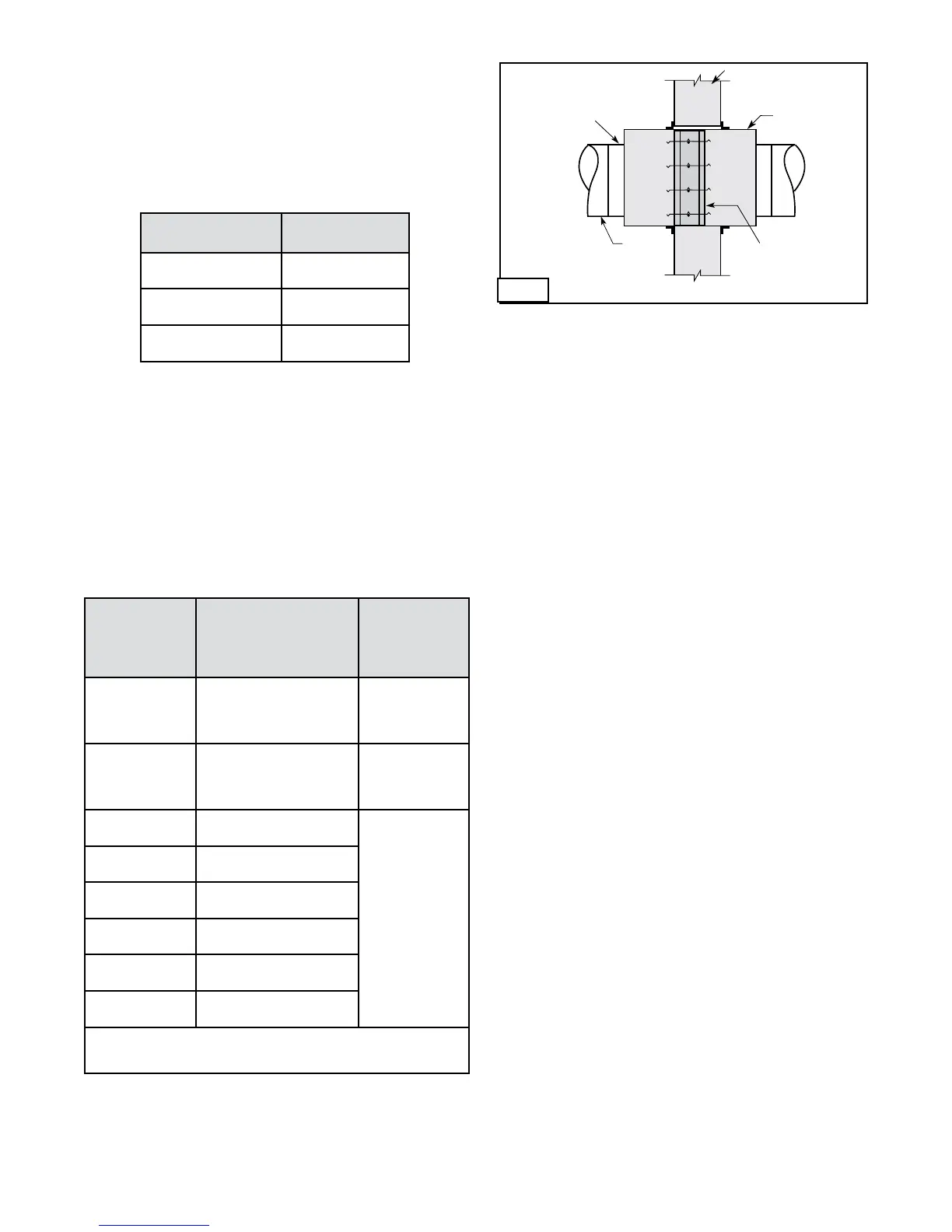

Wall or Floor

Sleeve

Duct

Damper

Type B

Wall or Floo

r

Sleeve

Duct

Damper

Type C, R

Type R and O

factory furnished

duct collars qualify

as breakaway

connections.

Fig. 2

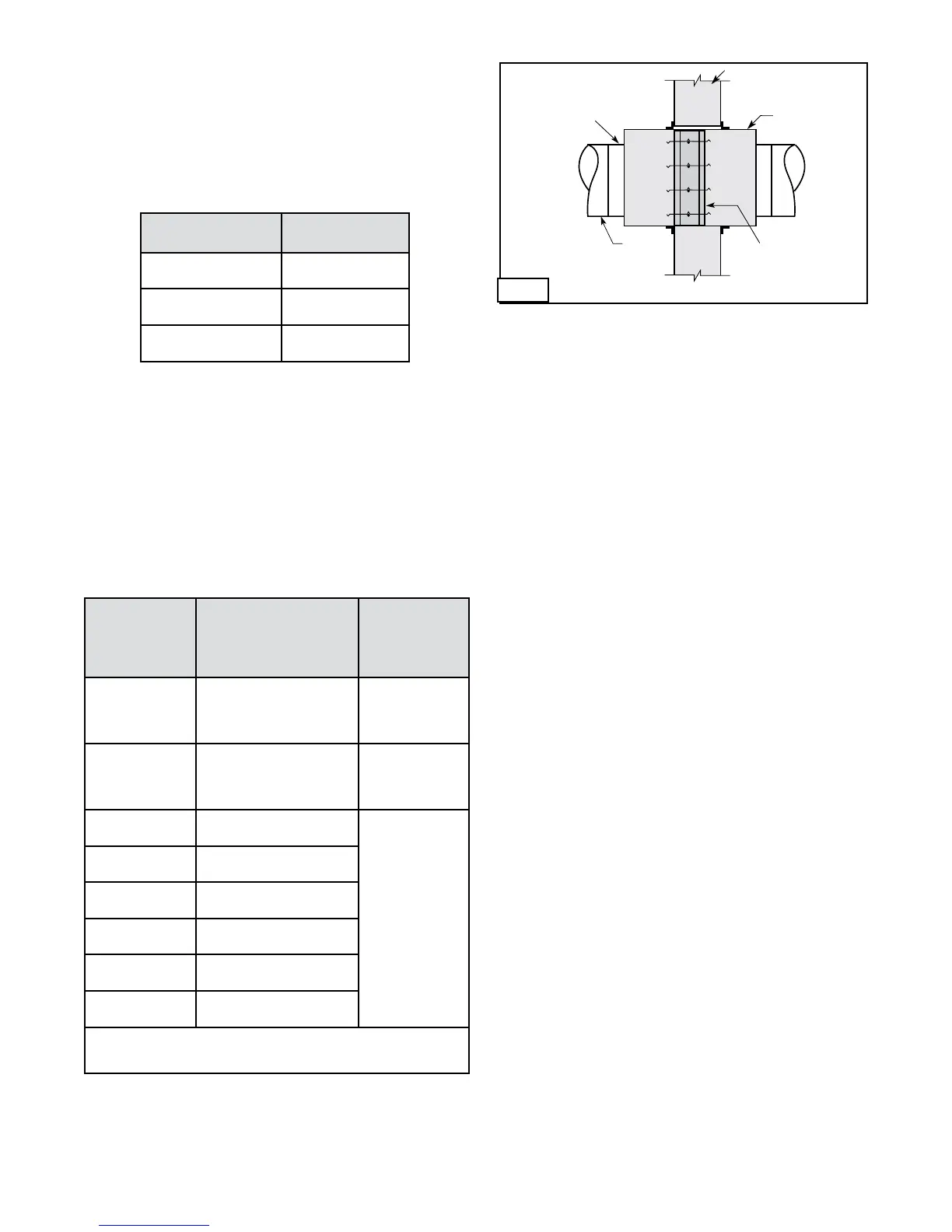

Wall Thickness

Dimension (T

W

)

Sleeve Length

Dimension (L)

4 - 6 in.

(102mm - 152mm)

16 in.

(406mm)

7 - 10 in.

(178mm - 254mm)

21 in.

(533mm)

11 - 13 in.

(279mm - 330mm)

24 in.

(610mm)

Sleeve Gauge Duct Dimension

Type of Duct

to Sleeve

Connection

Permitted

14 ga. (0.075 in.)

- 10 ga. (0.138

in.)

[2mm - 3.5mm]

All duct sizes

Rigid or

Breakaway

16 ga. (0.060 in.)

[1.5mm]

36 in. (914mm) max. width

24 in. (610mm) max.

height

24 in. (610mm) diameter

Rigid or

Breakaway

16 ga. (0.060 in.)

[1.5mm]

All duct sizes

Breakaway only

18 ga. (0.048 in.)

[1.2mm]

85 in. (2159mm) wide and

over

20 ga. (0.036 in.)

[0.9mm]

55 in. - 84 in. wide

(1397mm - 2134mm)

22 ga. (.030 in.)

[0.76mm]

31 in. - 54 in. wide

(787mm - 1372mm)

24 ga. (0.024)

[0.6mm]

13 in. - 30 in. wide

(330mm - 762mm)

26 ga. (0.018 in.)

[0.46mm]

12 in. wide and under

(305mm)

See page 7 for additional information on breakaway sleeve connections.

Sleeve thickness must not be less than the gauge of the connecting duct.

UL Standard 555 requires all ducts to terminate at fire damper sleeves.

4. SECURING THE DAMPER/SLEEVE ASSEMBLY

TO WALL AND FLOOR OPENINGS (for single side

retaining angle instructions, see supplements)

Damper/sleeve assemblies must be installed in wall and

floor openings using retaining angles on at least one

side of the wall or floor as described below:

•Retaining angles for 1½ hour rated dampers with a

width and height 48 in. (1219mm) or less must be a

minimum of 20 ga. (1mm). Retaining angles for all

3 hour rated dampers and all dampers with a width

or height greater than 48 in. (1219mm) must be a

minimum of 16 gauge (1.5mm). The leg of the retaining

angle on the damper sleeve shall be a minimum of

1¼ in. (32mm). The leg of the retaining angle on the

wall/floor shall be long enough to cover the annular

space and overlap the wall/floor by a minimum of 1 in.

(25mm).

•Retaininganglesmustbeattachedtothedamper

using one or more of the following methods of

attachment (refer to label on outside of sleeve for ‘No

Screw’ area):

•Tackorspotwelds

•#10(

3

/4 in. [19mm] max.) sheet metal screws

•

1

/4 in. (6mm) bolts and nuts

•

3

/16 in. (5mm) steel pop rivets

A minimum of two connections per side, top, and

bottom,12in.(305mm)O.C.maximumforopeningsof

48 in. W x 36 in. H (1219mm x 914mm) and less, and 6

in.(152mm)O.C.foropenings80in.Wx50in.H

(2032mm x 1270mm), 50 in. W x 72 in. H (1270mm x

1829mm), and 40 in. W x 72 in. H (1016mm x 1829mm)

or less. The angles must be attached to all 4 sides of the

sleeve. Ensure that attachment device does not interfere

with the operation of the damper and the free movement

of the damper blades. The angles need not be attached

to each other at the corners. Do not secure the retaining

angle to the fire separation (see Fig. 3).

•Retaininganglesshouldnotbefastenedtothewall/

floor material. The angles should only sandwich the

wall/floor and allow for damper expansion during

periods of intense heat.

4

IMPORTANT SAFETY DANGER! : To avoid causing

death or serious bodily harm to building occupants, do

not penetrate the ‘No Screw’ area designated on the

damper sleeve or the damper may not close properly.

The sleeve may extend a maximum of 16 in. (406mm)

beyond the wall or floor on the actuator side of the

damper and a maximum of 6 in. on the opposite side.

Recommended standard sleeve lengths for various wall

thicknesses are:

Loading...

Loading...