80 CLCH-SVX07C-EN

Coil Piping and Connections

Drain Pan Trapping

WARNING

No Step Surface!

Do not walk on the sheet metal drain pan. Walking on the drain pan could cause the supporting

metal to collapse. Failure of the drain pan could result in death or serious injury.

Threaded condensate drain connections are provided on only one side of the coil section. Pitch the

connection lines horizontal or downward toward an open drain. Trane recommends installing a

plug to facilitate cleaning of the trap. The drain connection sizes are:

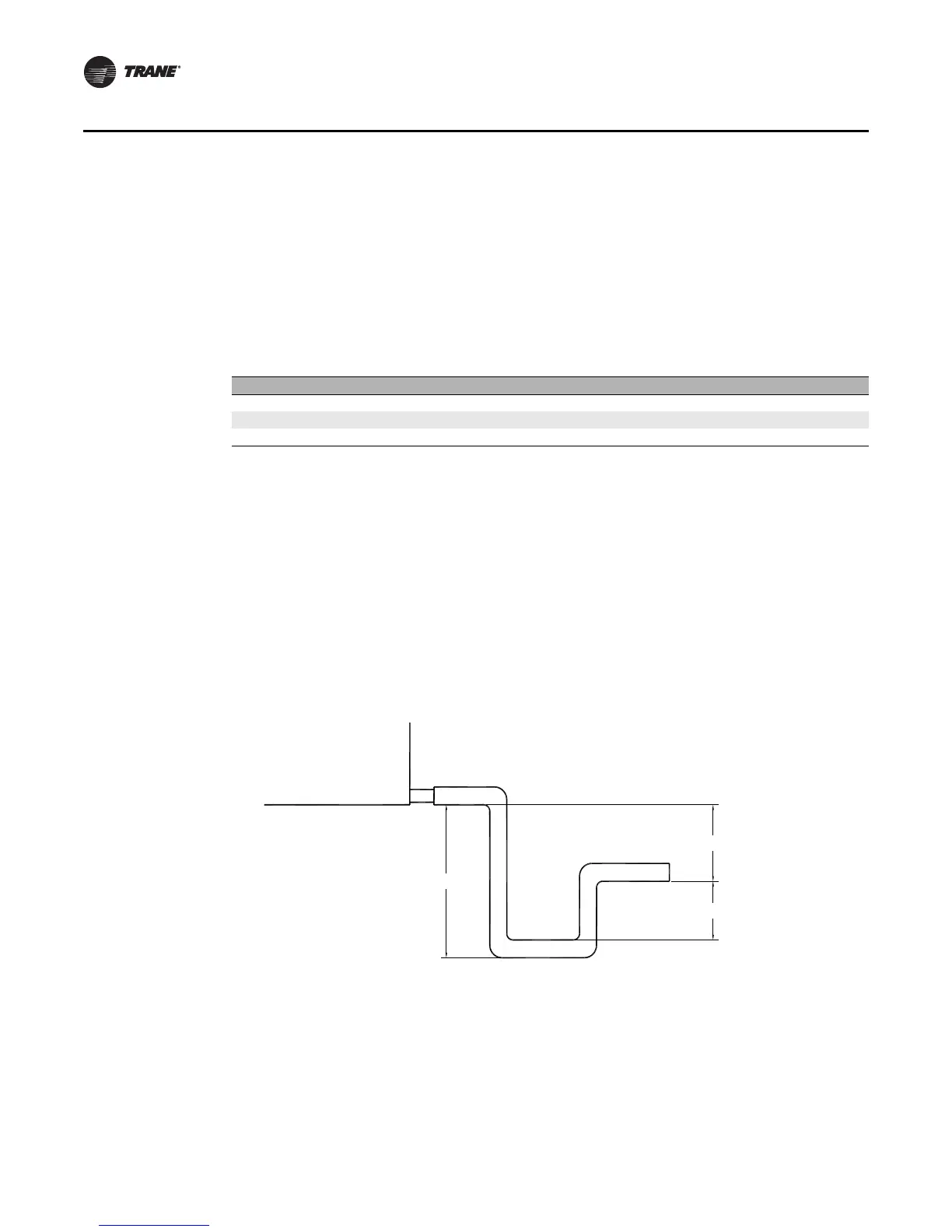

Figure 71 illustrates the proper trapping, piping, and operation of the trap. Use the formula under

the figure to determine the correct minimum depth for the condensate trap. If a section has a drain

pan for cleaning purposes only, it does not need a trap; however, a cap or shutoff valve should be

installed on the drain connection. Only sections handling condensate, such as a cooling coil section

or moisture eliminator section, require a trap.

NOTICE:

Water Damage!

When more than one section has a drain pain, trap each section individually. Connecting all

drains to a common line with only one trap could result in condensate retention and possible

water damage to the air handler or adjoining space.

Unit size NPT (national pipe thread) external connection

3-30 1-inch

35-57 1 1/4 inch

66-120 1 1/2 inch

Figure 71. Drain pan trapping for negative and positive pressure applications

H

J

L

Drain pan trapping for section

under negative pressure

L = H + J + pipe diameter where:

H = 1 inch for each inch of negative

pressure plus 1 inch

J = 1/2 H

Drain pan trapping for section

under positive pressure

L = H + J + pipe diameter where:

H = 1/2 inch (minimum)

J = 1/2 inch plus the unit positive static

pressure at coil discharge

(loaded filters)

Loading...

Loading...