•Transversejointsillustrated

can be applied as top and

bottom joints with Drive Slip

- side joints in duct heights

up to 20 inches (508mm)

See Fig. 13.

Round and Oval Duct Breakaway Connections

RoundorflatovalductsconnectedtoTypeRorOdamper

collars shall be attached with #10 (19mm) sheet metal

screws as follows:

•Ductsto22in.(558mm)wide(ordia.)andsmaller

shall have three screws.

•Ductslargerthan22in.(558mm)wide(ordia.)upto

and including 36 in. (914mm) wide (or dia.) shall have

five screws.

NOTE: All breakaway connections described may have duct

sealant applied, PA2084T duct sealant adhesive

manufactured by Precision, DP1010 water base duct

sealant manufactured by Design Polymetrics, Grey Pookie

orDuctmatePROseal

®

in accordance with SMACNA

recommendations.

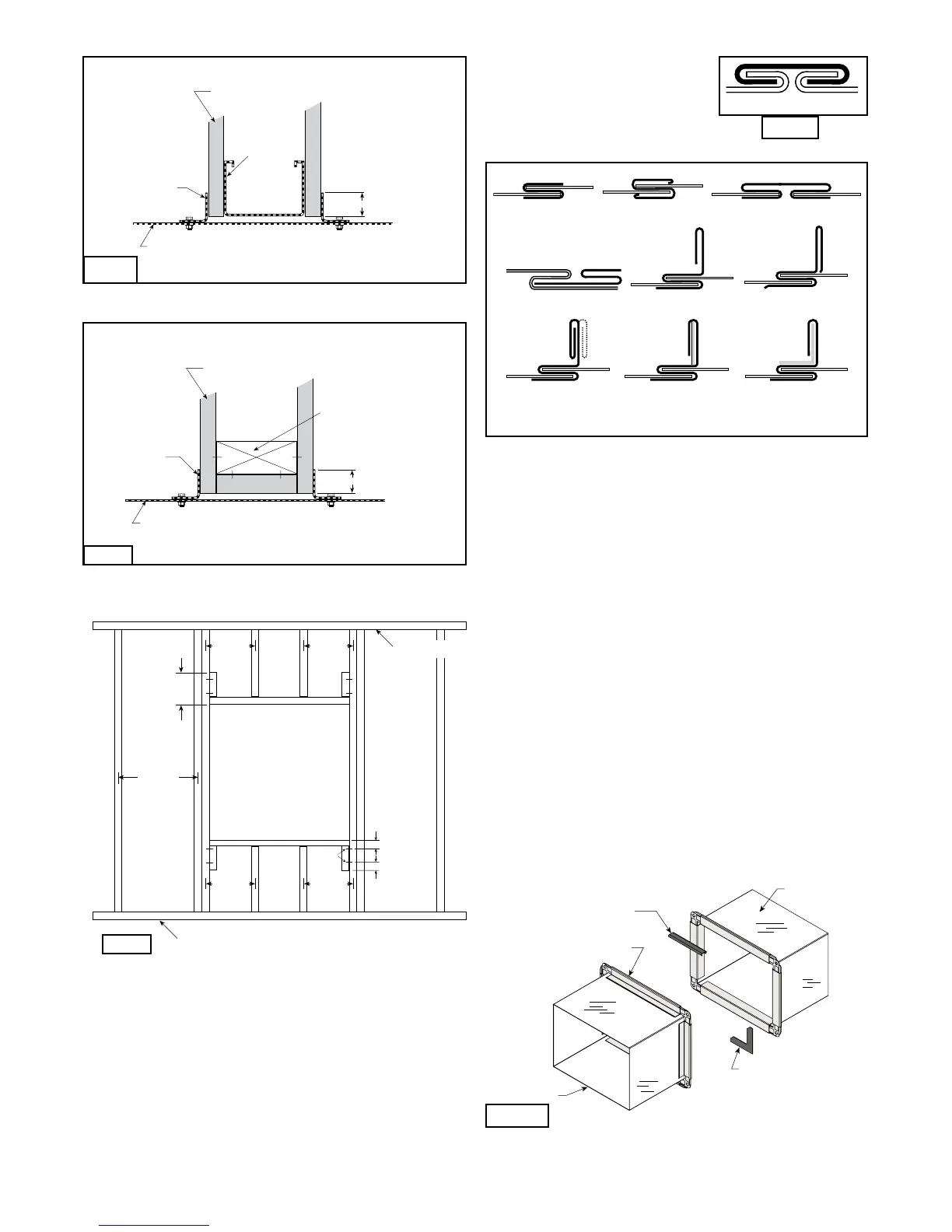

Manufactured Flanged System Breakaway

Connections

Flanged connection systems manufactured by Ductmate,

Ward, and Nexus are approved as breakaway connections

when installed as illustrated (Fig. 15).

Wooden Stud Construction

In wood stud construction,

gypsum wallboard must cover

all wood stud surfaces.

Gypsum Wallboard

Stud or Runner

Retaining

Angle

1 in. Min.

Damper

Sleeve

In metal stud construction,

exposed steel surfaces need

not be covered with gypsum

wallboard.

Gypsum Wallboar d

Stud or Runner

Retaining

Angle

1 in. Min.

Damper

Sleeve

Fig. 11

12 in.

24 in. o.c.

Maximum

Floor Runner

Ceiling Runner

24 in. o.c.

Maximum

(metal studs)

24 in. o.c.

Maximum

(metal studs)

16 in. o.c.

Maximum

(wood studs)

16 in. o.c.

Maximum

(wood studs)

2 in. (51mm)

2 in. (51mm)

2 Panhead

Screws

Fig. 12

9. DUCT-SLEEVE CONNECTIONS

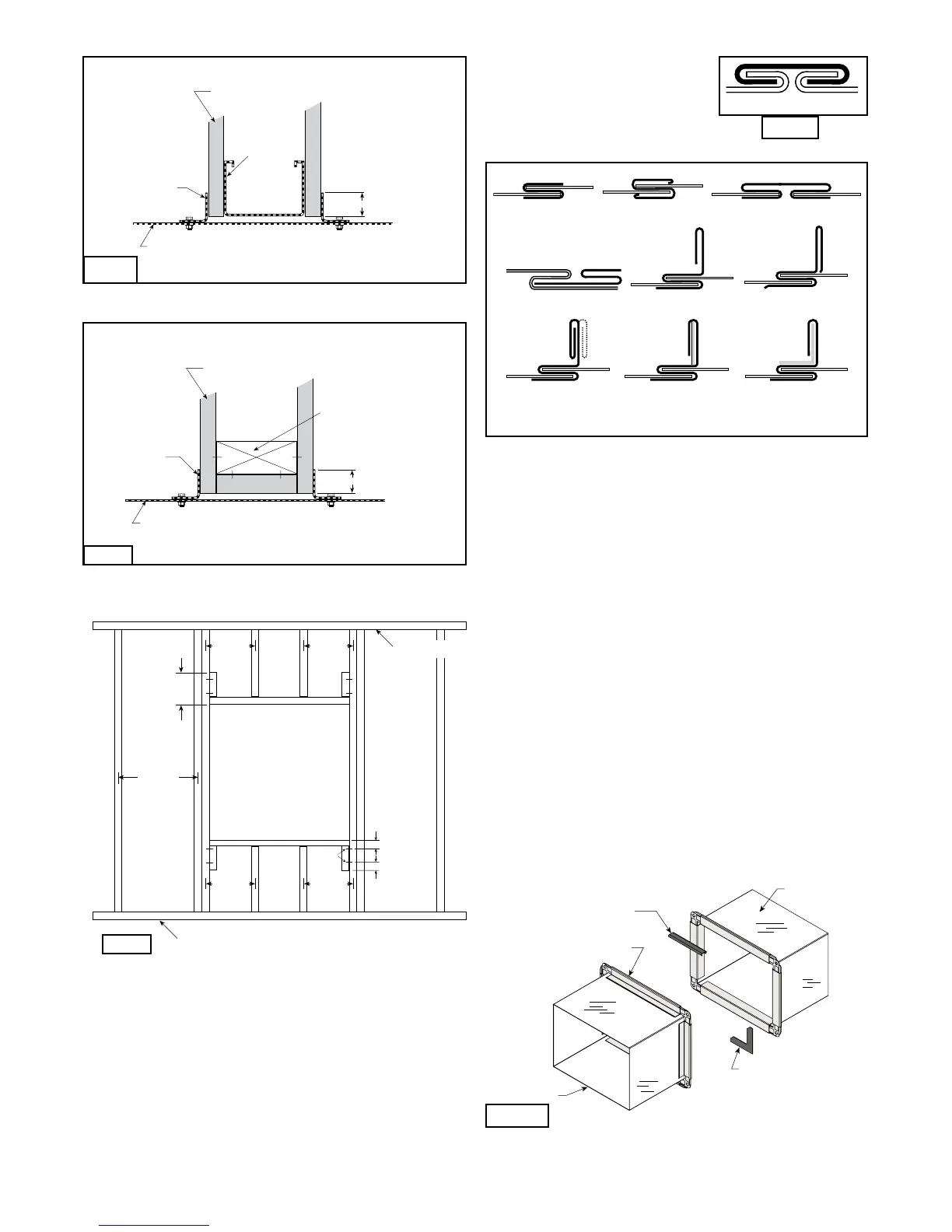

Traditional Breakaway Style Transverse Joints

Transverse joints illustrated at right have always been

approved as breakaway connections. SMACNA testing

has also approved the following variations as breakaway

connections.

•Thebreakawayconnectionsshown(Fig. 14) can

be applied with maximum of two #10 (19mm)

sheet metal screws on each side and on the

bottom located in the center of the slip pocket and

penetrating both sides of the slip pocket.

Fig. 13

Plain “S” Slip Hemmed “S” Slip Double “S” Slip

Inside Slip Joint Standing “S” Standing “S” (Alt.)

Standing “S” (Alt.) Standing “S” Standing “S”

(Bar Reinforced) (Angle Reinforced)

Fig. 14

Fire Damper Sleeve

Neoprene gasket

between all angles

Flanged system angles

(Attach per

manufacturer's

instructions)

Duct

Do not bolt corners

6 in. long

1

/16 in. max.

thickness plastic cleats;

12 in. c-c (min. 1 per side)

Fig. 15

7

Metal Stud Construction

Wooden Stud Construction

In wood stud construction,

gypsum wallboard must cover

all wood stud surfaces.

Gypsum Wallboard

Stud or Runner

Retaining

Angle

1 in. Min.

Damper

Sleeve

In metal stud construction,

exposed steel surfaces need

not be covered with gypsum

wallboard.

Gypsum Wallboar d

Stud or Runner

Retaining

Angle

1 in. Min.

Damper

Sleeve

Fig. 10

Loading...

Loading...