62 CLCH-SVX07C-EN

Component Installation Requirements

Seismic Isolation Requirements

Air handling equipment manufactured by Trane is capable of structurally and operationally

withstanding the seismic response criteria as required by the International Building Codes (IBC)

2000,2003, 2006, 2009. Trane has third-party certification for IBC compliance for seismic

applications for unit sizes 3-30. Certification for larger sizes is in process.

Note: If seismic isolation has been specified, the following requirements must be adhered to for

installation. Failure to follow these instruction would void the warranty.

Anchor Requirements

Single Level Design Break

Size 3-30 - Grade to Roof Mounted (0<=Sds<=1.85) Non-Isolated

4000 psi concrete

• 3/8-inch diameter Hilti Kwik Bolt TZ carbon steel concrete anchors attached to unit base rails.

• Quantity (2) anchors at AHU ends, (quantity (1) at each side)

• Quantity (2) anchors at AHU unit splits, quantity (1) at each side, staggered.

• 2-inch minimum anchor embedment

• 4-3/8-inch minimum distance to the nearest edge

• 4-inch minimum concrete slab thickness

Steel dunnage/steel curb

3/8-inch diameter ASTM A325 or SAE grade 5 bolts attached to unit base located as noted above

or 1-inch long 3/16-inch welds at unit base located as noted above.

Stacked Design Break

Size 3-30 – Grade to Roof Mounted (0<=Sds<=1.85) Non-Isolated

4000 psi concrete

• 1/2-inch diameter Hilti Kwik Bolt TZ carbon steel concrete anchors attached to unit base rails.

• Quantity (2) anchors at AHU ends (quantity (1) at each side).

• Quantity (2) anchors at AHU unit splits, (quantity (1) at each side, staggered).

• 3 1/4-inch minimum anchor embedment

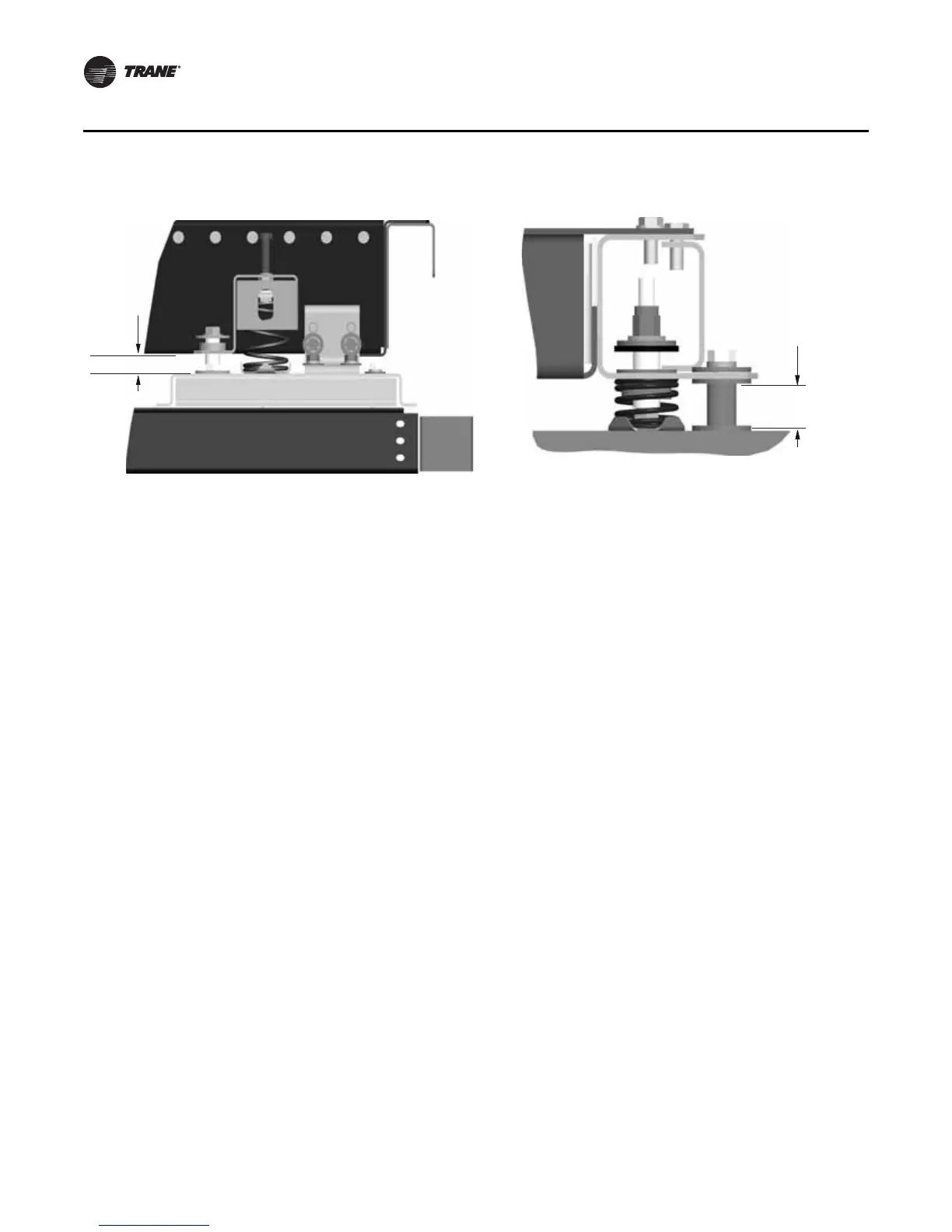

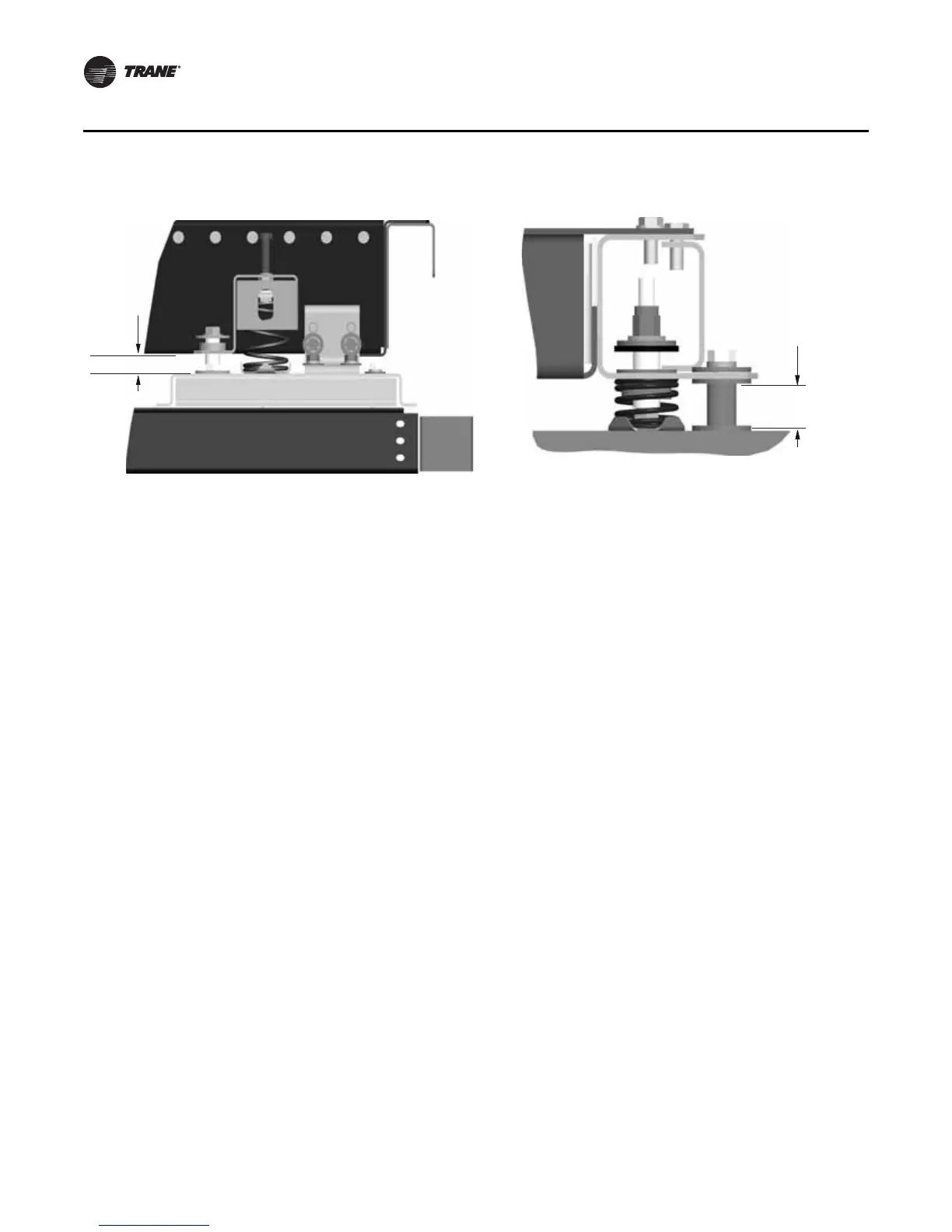

Figure 53. Isolator tie-down removal for unit sizes 66-120 Figure 54. Belt-drive plenum fan tie down

Required

clearance

Loading...

Loading...