30 CLCH-SVX07C-EN

Installation - Mechanical

Unit Assembly

Note: Air handlers often include optional factory-provided casing penetration entry points for

field-provided wiring. Consider overall unit serviceability and accessibility before

mounting, running wires (power), making cabinet penetrations, or mounting any

components to the cabinet.

See “Component Installation Requirements” on page 49 for special assembly/installation

considerations.

Removing the Shipping Skid

Remove the wooden shipping blocks, wooden toe cleat if there is one, and end cleats prior to

lowering unit into final position or installing the unit to the roof curb.

Ceiling Suspension for Indoor Air Handlers Sizes 3-57

Note: Ceiling suspension is not recommended for units larger than size 57 unless using a field-

provided mounting frame.

Using a Field-Provided Mounting Frame

WARNING

Heavy Objects!

If a field-provided mounting frame is used for ceiling suspension, the installer/contractor must

provide a ceiling-suspended mounting frame designed to support the length, width, and weight

of the entire air-handling unit. Failure to use proper mounting frame, structural channels, and

hangers could result in unit falling from its mounting location which could result in death or

serious injury.

See “Unit Dimensions and Weights” on page 16 for approximate weights.

Note: It is the building engineer’s responsibility to size the structural channels and to provide the

appropriate hangers.

Structural channels in a field-provided frame can be mounted parallel to airflow or perpendicular

to airflow:

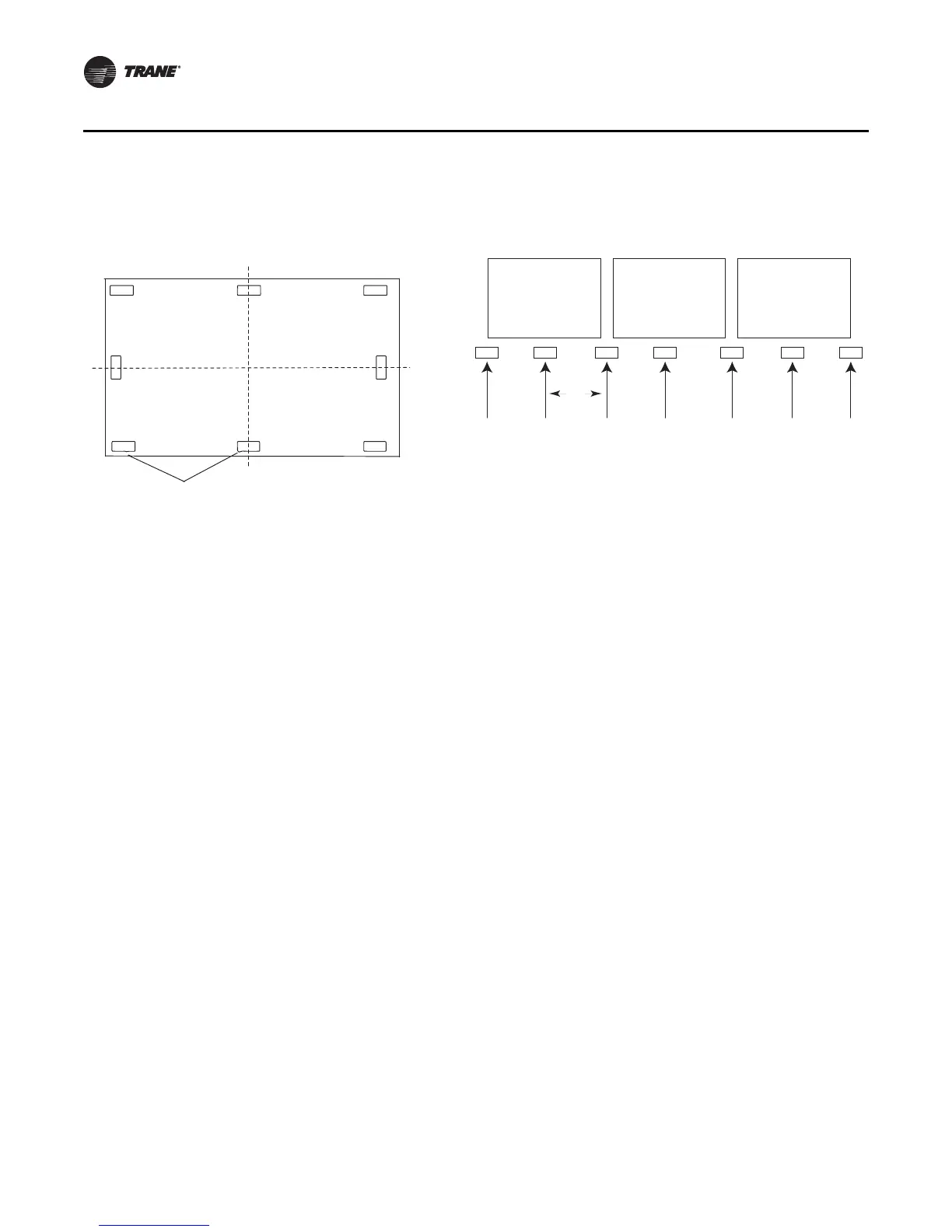

Figure 11. Piers located in each corner and spaced

evenly every four feet

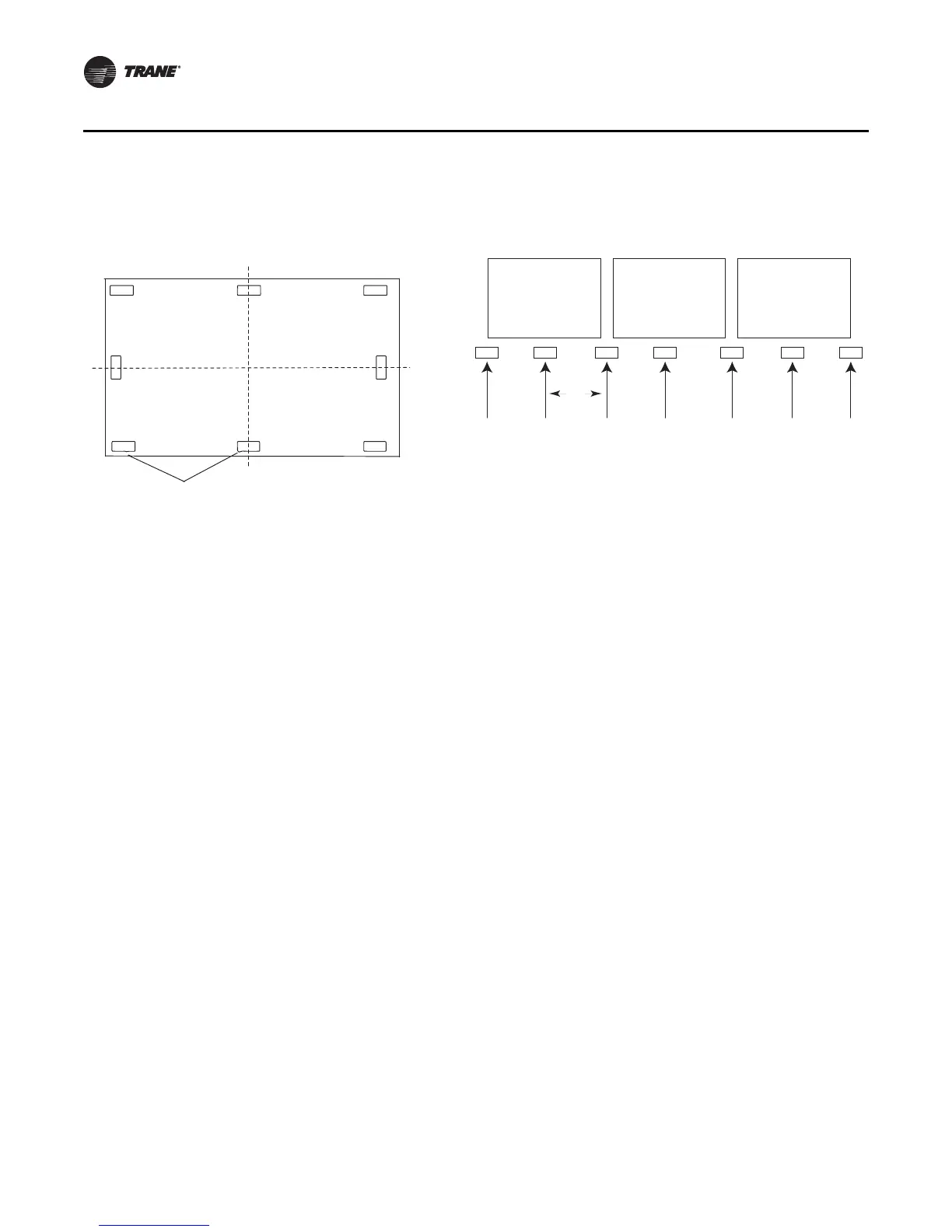

Figure 12. Side view with two shipping splits - locate one

pier directly under each shipping split

Note: Piers beneath shipping splits must be structurally sound to support the weight of the unit.

Loading...

Loading...