3-98 OM 25-3503 us – Edition 4.1 * * 2503_3503b340.fm

Operation

Re-equipping

Injury hazard due to modification work!

Can cause serious injury or death.

• Observe the following instructions:

• Stop the engine

• Raise the control lever base

• Re-equip attachments only with suitable tools

• Do not align components with your fingers or your hands but use suita-

ble tools – crushing hazard!

• Once you have re-equipped the attachments, or before starting work,

ensure that the attachment is safely locked with the stick and the tilt rod, or

with the Powertilt unit (option).

• Release the pressure – see chapter 3.50 Releasing the pressure on the

operating hydraulics on page 3-88

• Follow the safety instructions – see chapter 3.51 Re-equipping attachments

on page 3-89

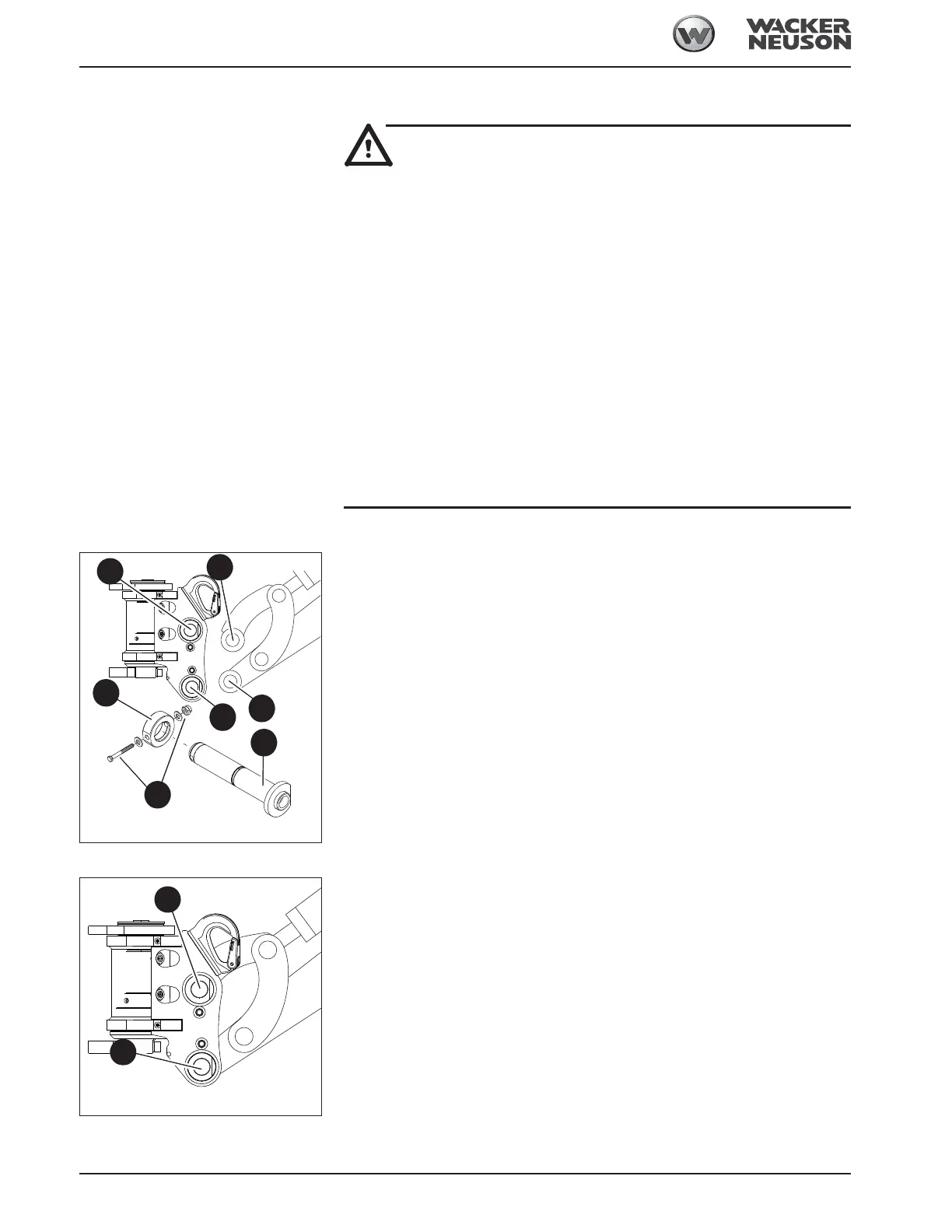

Installing the Powertilt unit

Proceed as follows:

☞ Lower the Powertilt unit to the ground with its flat side facing down

☞ Grease the joints and the pins before inserting them

☞ Start the engine

☞ Straighten the stick so that bores D and E are flush

☞ Insert greased pin F

☞ Install ring J and tighten the securing elements G

☞ Actuate the stick cylinder until bores H and I are flush

☞ Insert greased pin F

☞ Install ring J and tighten the securing elements G

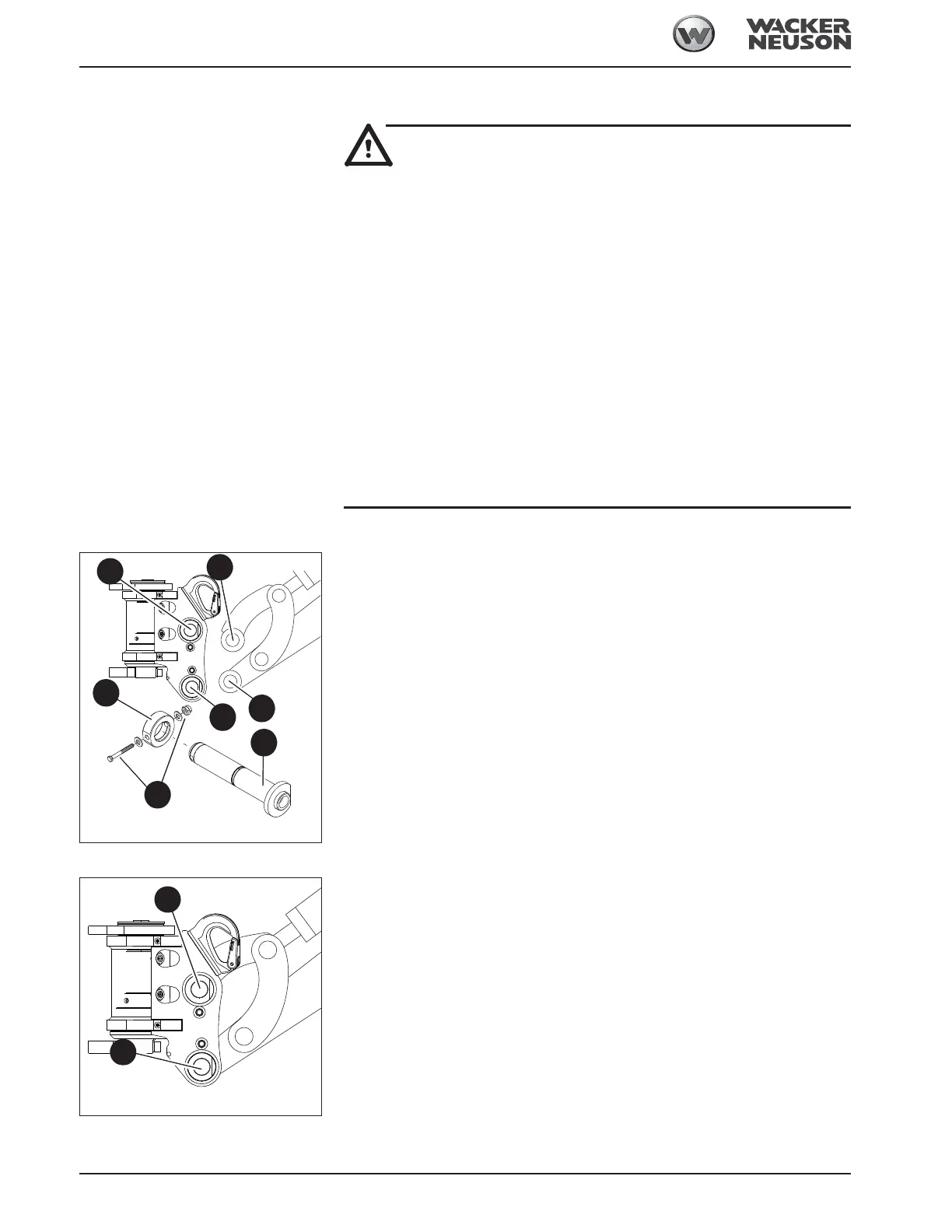

Removing the Powertilt unit

Re-equip as follows:

☞ Lower the Powertilt unit to the ground with its flat side facing down

☞ Stop the engine

☞ Raise the control lever base

☞ Remove the ring and the securing elements

☞ First remove pin A, and then pin B. Carefully expel pins that are stuck with a hammer

and a brass punch

If pin A is stuck:

☞ Start the engine

☞ Slighty raise and lower the boom to take the load off the pin

☞ Stop the engine

☞ Raise the control lever base

Fig. 229: Assembly

D

F

E

H

I

G

J

Fig. 230: Removing

A

B

Loading...

Loading...