OM 803 us – Edition 3.7 * 803b340.fm 3-77

Operation

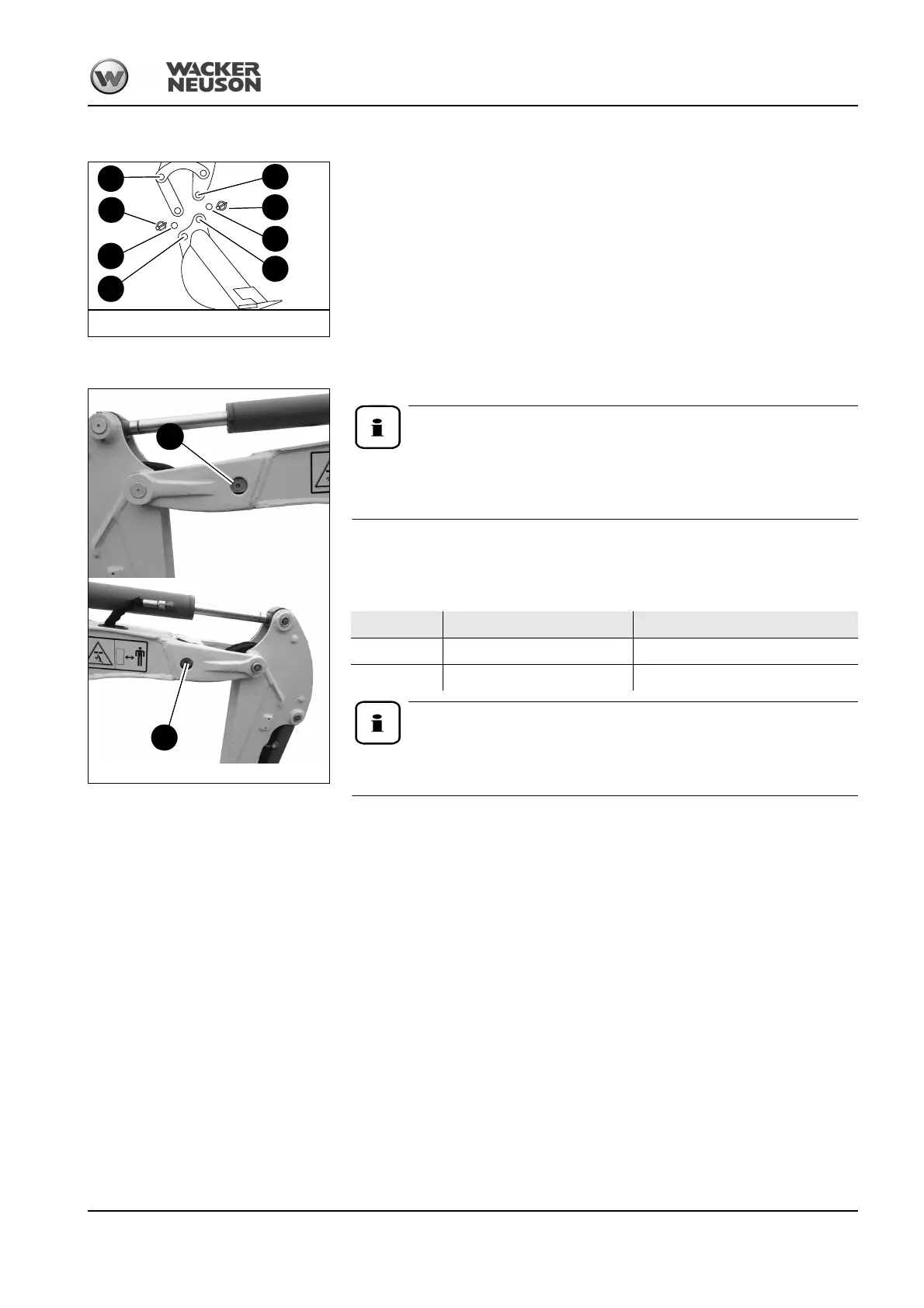

Installing a bucket

• Install a bucket only if it is positioned on level ground with the flat side facing downward

• Apply grease to the pins and joints before inserting the pins

• Start the engine

• Straighten the stick so that bores D and E are flush

• Insert greased pin F

• Actuate the stick cylinder until bores H and I are flush

• Insert the greased pin J

• Install linch pins K

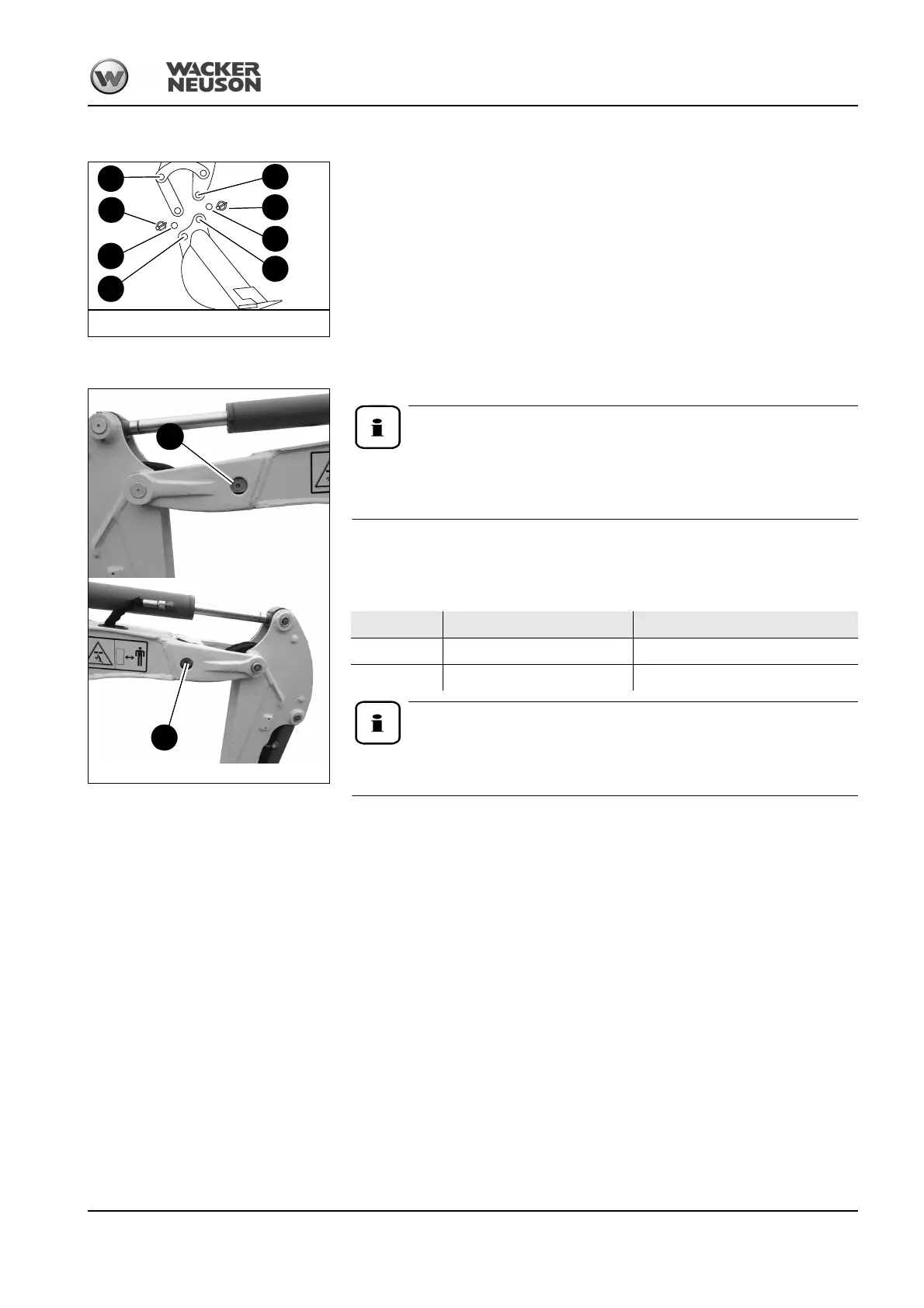

Connections for auxiliary hydraulics

For hammer operation we recommend installing the hydraulic lines up to the

stick in order to avoid damage – see chapter Connections for auxiliary

hydraulics (stick hose routing option) on page 3-78.

Auxiliary hydraulics can be connected as required.

If the machine is equipped with the double-action auxiliary hydraulics option, only the flow

direction of the hydraulic oil changes.

Follow the instructions in the Operator’s Manual of the attachment manufac-

turer for connecting the auxiliary hydraulics to an attachment.

Connect and disconnect as follows:

☞Park the machine on level and horizontal ground.

☞Extend the stick cylinder halfway through.

☞Stop the engine.

☞Release the pressure on the operating hydraulics

– see chapter 3.19 Pressure release on the auxiliary hydraulics on page 3-75.

➥The attachment couplings can be connected.

☞Raise the lock lever.

☞Remove the starting key.

Fig. 167: Installing a bucket

D

H

I

E

F

K

K

J

Fig. 168: Auxiliary hydraulics connections

U

T

Connection Left side of boom Right side of boom

T

☞Return line

U

☞Pressure line

Loading...

Loading...