OM 803 us – Edition 3.7 * 803b530.fm 5-25

Maintenance

5.9 Tracks

Track wear can vary according to work and ground conditions.

Checking track tension

Crushing hazard when working under the machine!

Causes serious injury or death.

• Ensure that no one is in the danger zone!

• Support the machine so as to allow the tracks to sag freely.

1 Park the machine on firm, level and horizontal ground.

2 Raise the machine evenly and horizontally by means of the boom and the stabi-

lizer blade.

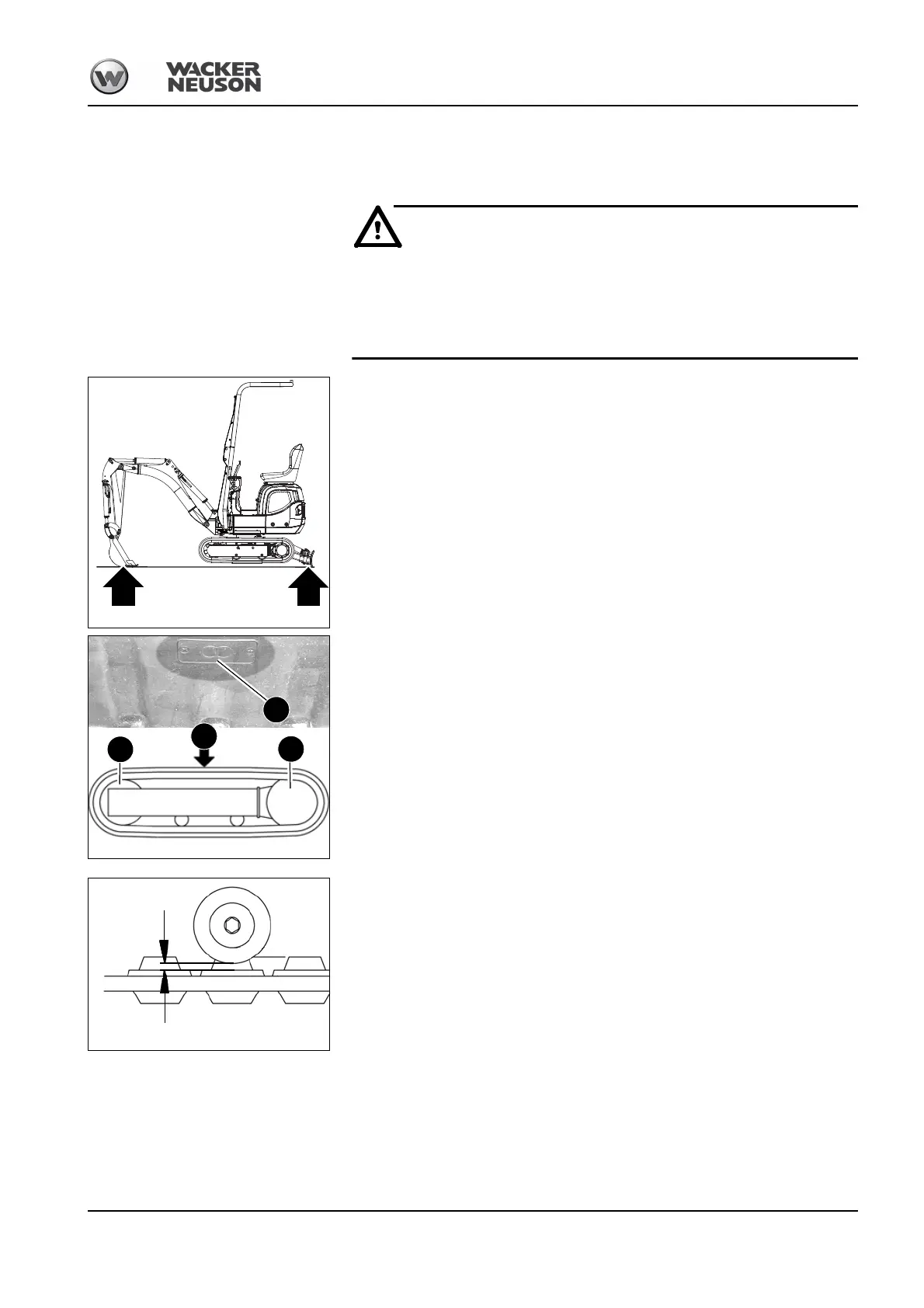

3 Place the tracks so that mark B is in the middle between the drive pinion C and the

track tension roller D.

4 Stop the engine.

5 Raise the control lever base.

6 Remove the starting key and carry it with you.

7 Adjust the correct track tension if the play between the track roller and the track is

not 15 – 20 mm (0.6 – 0.8 in).

Fig. 216: Raising the machine

Fig. 217: Rubber track mark

B

B

D

C

Fig. 218: Measuring distance

15 – 20 mm

0.6 – 0.8 in

Maintenance

Loading...

Loading...