5/2011

3-3

Phaser 4600/4620 Printer Service Manual

IQ1

Image Quality

Revision - Xerox Internal Use Only

IQ1 Image Quality Entry RAP

The purpose of this RAP is to establish the source and type of imaging defect. Print-quality

defects can be attributed to printer components, consumables, media, internal software, exter-

nal software applications, and environmental conditions. To successfully troubleshoot print-

quality problems, eliminate as many variables as possible. First, recreate the perceived defect

using the customer’s job or test print. Use approved laser paper from a fresh ream acclimated

to room temperature and humidity.

If the print-quality defect is still present after printing on approved media from an unopened

ream of paper, investigate software applications being used and environmental conditions.

Check the temperature and humidity under which the printer is operating. Compare this to the

“Environmental Specifications”. Extreme temperature and humidity can adversely affect the

printer’s xerographic and fusing characteristics.

When analyzing a imaging defect, determine if the defect is repeating or random. Continuous

defects in the process direction, such as voids and lines, are the most difficult to diagnose.

Check the CRU life counters for end of life conditions. Inspect the visible surfaces of all rollers

for obvious defects. If a cursory inspection does not reveal any obvious defects, continue trou-

bleshooting the defect, starting with the list of initial actions.

Initial Actions

Use the following steps to determine which part of the system is at fault.

1. If possible, discuss the defect with the customer to determine if the perceived defect is

outside the printer’s image specifications.

2. Ensure all connections to the printer are secure.

3. Check the CRU life counts. Replace components at end of life.

4. Cycle system power.

5. Make sure the printer is positioned to allow adequate airflow at all vents. Refer to GP 17,

Installation Space Requirements.

6. Make sure the printer’s interior is clean.

7. Check the tray guides.

8. Use the customer’s print job to check defect reoccurrence. If the defect persists, begin to

isolate the defect by attempting to identify the component responsible.

9. Check stored tray settings for media size and type.

10. Check image adjustment and print mode settings being used.

Defects Associated with Specific Components

To aid with defect diagnosis, listed below are defects associated with specific components.

Laser Unit image defects:

• Black Print

• Vertical white lines

• Curved lines

Transfer Roller image defects:

• Uneven Density

• Background contamination

• Ghosting

• Vertical white lines

• Vertical black line or band

• Stains on the page back

Fuser image defects:

• Ghosting

• Stains on the page back or front

• Poor image adhesion

Drum Cartridge image defects:

• Uneven density

• Background contamination

• Spots, smudges, or smears

• Ghosting

• Vertical white lines

• Vertical black line or band

• Stains on the page front

• Blank prints

• Black prints

• Horizontal Black lines or bands

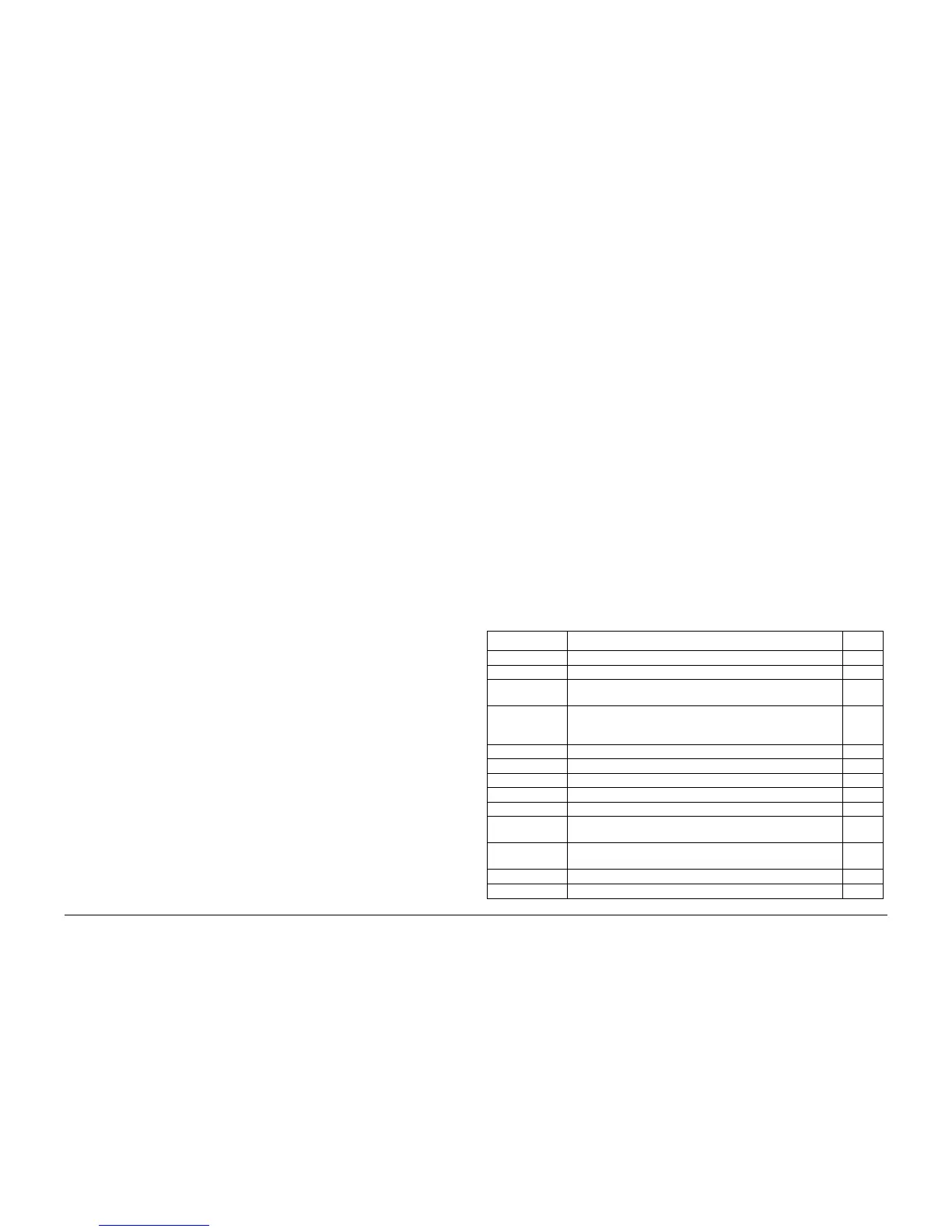

After determining the defect type and possible source, match the defect with thoses listed in

Table 1. Go to the RAP listed to correct the defect.

Image Defect Definitions

Table 1 lists image defect definitions and the RAP(s) used to correct the problem.

Table 1 Image Defect Definitions

Defect Definition Go To

Deletions There are areas (lines, bands, spots) missing entirely. IQ2

Unfused Image Part or all of the image is infused. Refer to the specification. IQ3

Resolution At 600 dpi, the two pixel lines and halftone patches cannot be

reproduced clearly on the print.

IQ4

Skips and

Smears

Skip - Image loss or stretching in horizontal bands.

Smear - Image distortion in bands across the process direction

that appear blurred or compressed.

IQ2

Spots There are spots of toner on the page. IQ7

Skewed Image Angular image displacement from its intended position. IQ5

Light Prints The overall image density is too light. IQ6

Blank Prints Prints with no visible image. IQ8

Black Prints The print is completely covered with toner with no image. IQ9

Process Deltions Areas of the image are extremely light or missing entirely.

Defects run vertically in the direction of paper movement.

IQ2

Scan Deletions Areas of the image are extremely light or missing entirely.

Defects run horizontally across the page.

IQ2

Process Streaks Extraneous dark lines/bands in the process direction. IQ10

Scan Streaks Extraneous dark lines/bands in the direction of scan. IQ11

Loading...

Loading...