5/2011

6-14

Phaser 4600/4620 Printer Service Manual

GP 13, GP 14

Revision - Xerox Internal Use Only

General Procedures/Information

GP 13 How to Check a Switch

Use this procedure to check the operation of a switch.

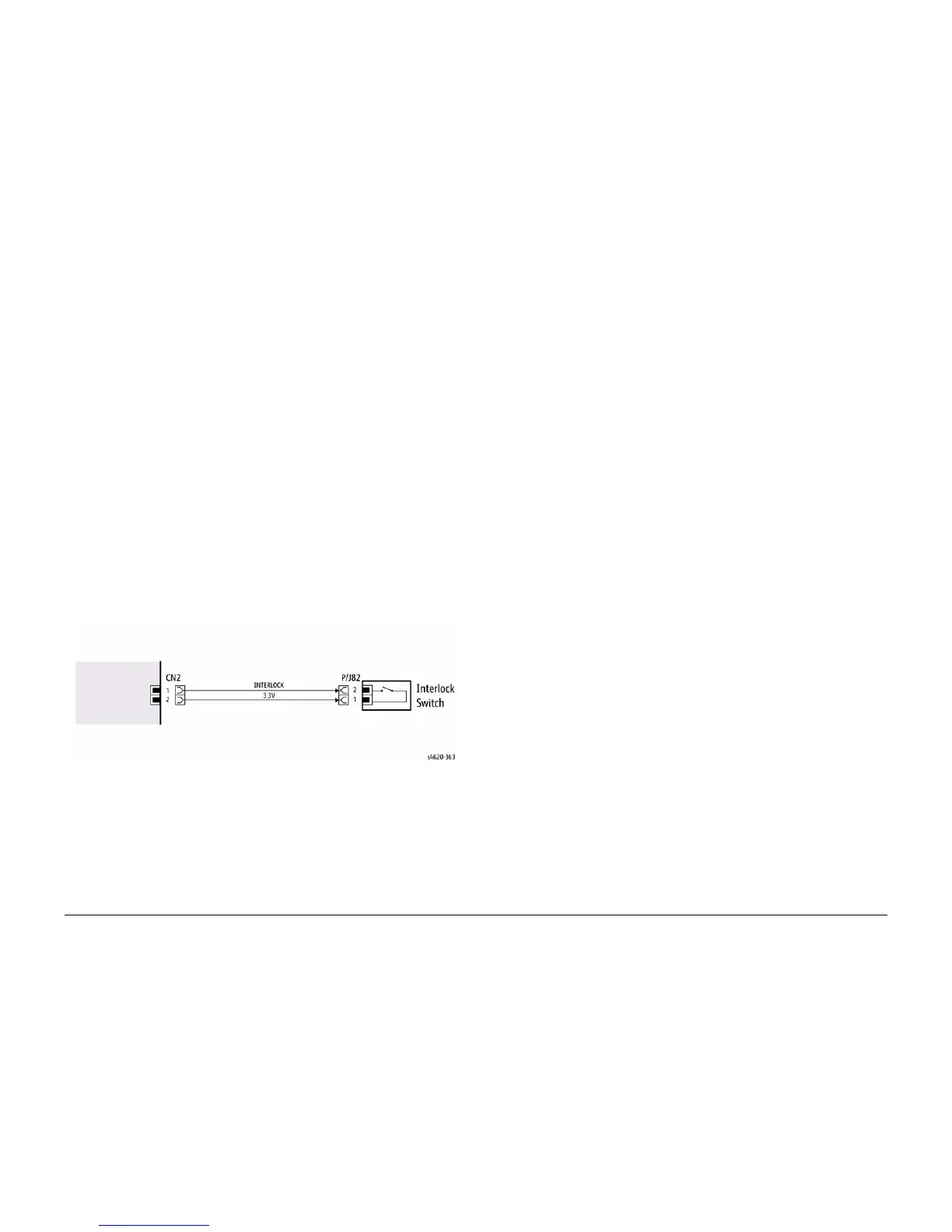

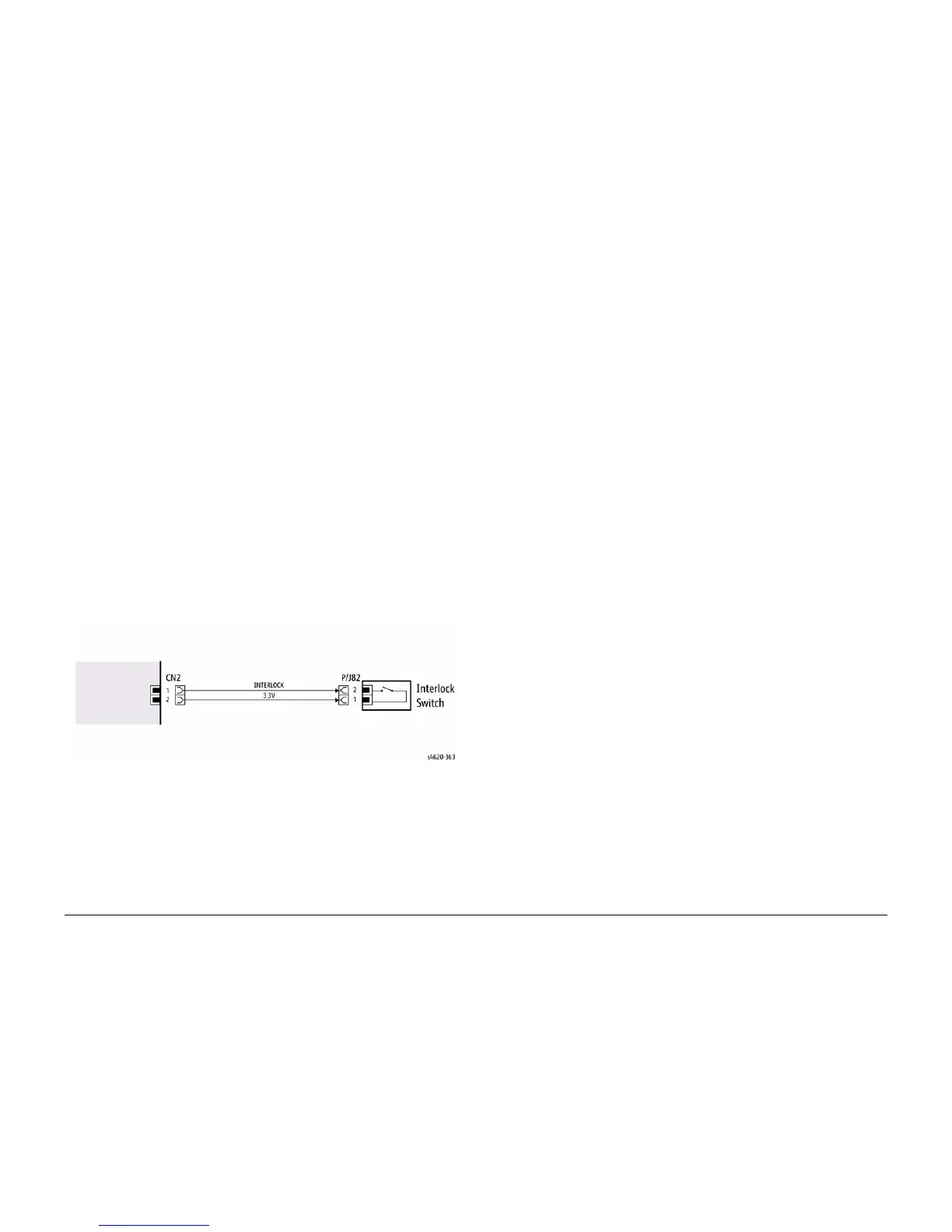

NOTE: Figure 1 shows an interlock switch actuated by the closing of a door.

Initial Actions

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

Manually check that the switch operates. Ensure that the magnet or other actuator has enough

mechanical movement to operate the switch.

NOTE: The voltages, PJ numbers, pin numbers and PWB names shown are an example only.

Go to the wiring diagram associated with the RAP for the correct information.

Procedure

1. Enter diagnostics and check the switch. The switch is operating correctly, check and

adjust the mechanism that actuates the switch

2. Refer to Figure 1, then disconnect T072.

3. +5V is available between pin 1 and pin 2 on the wiring side of the connector.

4. +5V is available at PJ5 between pins 3 and 4 on the PWB.

5. Check the supply voltage. If +5V is available, install a new PWB.

6. Check the wiring between PJ5 and T072. Repair or install new parts as necessary.

7. Install a new switch.

Figure 1 Example Switch Wiring Diagram

GP 14 Separate System Modules

Use this procedure to remove the Mailbox or Finisher modules from the printer.

Description

Most service procedures for finishing modules require separation of the module from the

printer. Only 1 person is required to separate the Mailbox or Finisher from the printer.

WARNING

Switch off the electricity to the machine. Disconnect the power cord from the customer

supply while performing tasks that do not need electricity. Electricity can cause death or

injury. Moving parts can cause injury.

CAUTION

Always move the printer separately from the Finisher, Mailbox, and optional trays.

1. Clear the media path and output trays.

2. Remove the output trays from the mailbox before servicing the module.

3. Lift the module to clear the support brackets.

4. Place the module on a suitable work surface to avoid damage.

5. Check the position of the option connector before module installation on the IOT.

Loading...

Loading...