5/2011

8-6

Phaser 4600/4620 Printer Service Manual

Sensors

Revision - Xerox Internal Use Only

Principles of Operation

Sensors in the Media Path

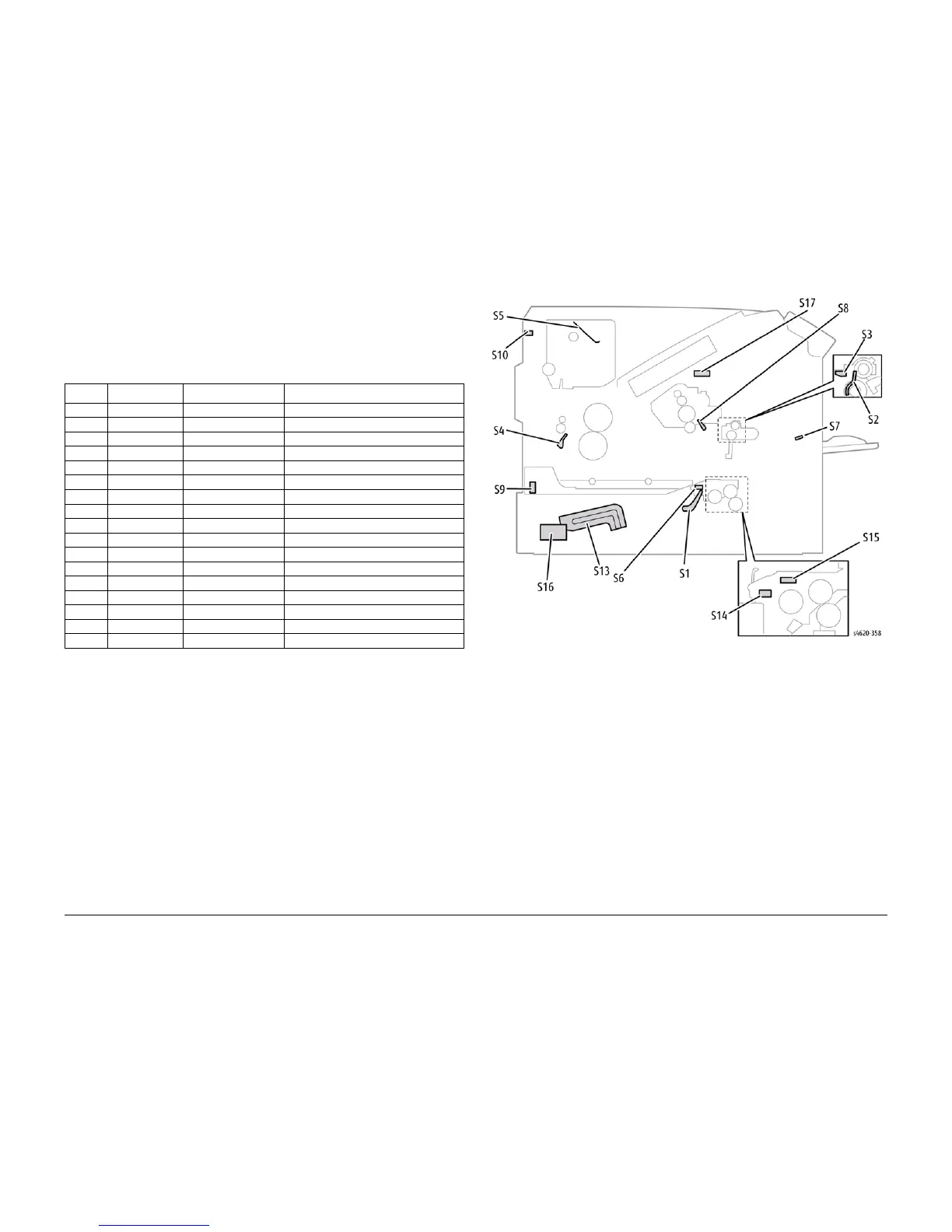

Figure 3 shows the location and designation of sensors located in the media path. Error detec-

tion is based on media transport timing through the sensing area.

Table 1 briefly describes the type and function of sensors and switches used to determine

operational status and detect jams or failures.

Media Size Sensing

Trays 2 and optional feeders detect media size using an array of microswitches (Size Switch)

mounted in the tray cavity. When the tray end guide is adjusted, the guide changes the Size

Switch actuator positions. Actuating different combinations of the Size Switch produces differ-

ent combinations of high and low signals. These signals identify what size media is loaded and

what to display on the Control Panel. Also, actuation of the Size Switch signals the tray is

present and closed to the MCU Board.

Media Present Sensing

When the last sheet is fed from any tray, the No Paper Sensor actuator drops to block the No

Paper Sensor. Feeding is inhibited until media is loaded into the tray.

Media Level Sensing

As media is fed from the tray, the media level drops. When the level reaches a certain point, an

actuator unblocks the Level Sensor signaling the control logic to raise the tray bottom plate

with the Lift Motor. Raising the tray bottom plate pushes media up to achieve optimum force

against the Nudger Roller and blocks the Level Sensor resuming paper feed. This loop contin-

ues until the No Paper sensor is activated. Paper level sensing operates the same way for

Trays 2 through 6. Tray 1 uses No Paper sensing only.

Figure 3 IOT Sensors

Table 1 List of Sensor and Interlock Functions

Number Name Type Function

S1 No paper Photo-receptive Signals no media remaining in Tray 2

S2 Registration Photo-receptive Signals leading edge at registration

S3 Feed Photo-receptive Signals leading edge registered

S4 Exit Photo-receptive Signals media present at exit

S5 Stack Full Photo-receptive Signals output tray full

S6 Duplex Photo-receptive Signals media present

S7 No paper Photo-receptive Signals no media remaining in Tray 1

S8 ADC Photo-reflective Monitors Toner density

S9 Duplex Photo-receptive Signals media present (leading edge)

S10 Rear Door Microswitch Signals Rear Door open

S11 Port open Photo-receptive Signals Waste Toner Cartridge installed

S12 Top Door Microswitch Signals Top Door open

S13 Size Switch Microswitch Signals media size in tray

S14 Pick Photo-receptive Signals Pick Assembly position

S15 Level Photo-receptive Signals lift motor to raise tray bottom

S16 Environmental pcb Monitors temperature and humidity

S17 Internal temp Thermistor Monitors internal temperature