12 Drive Control, Duty Modes, and Programming

YASKAWA TOEPC71061752B GA500 Drive Installation & Primary Operation 81

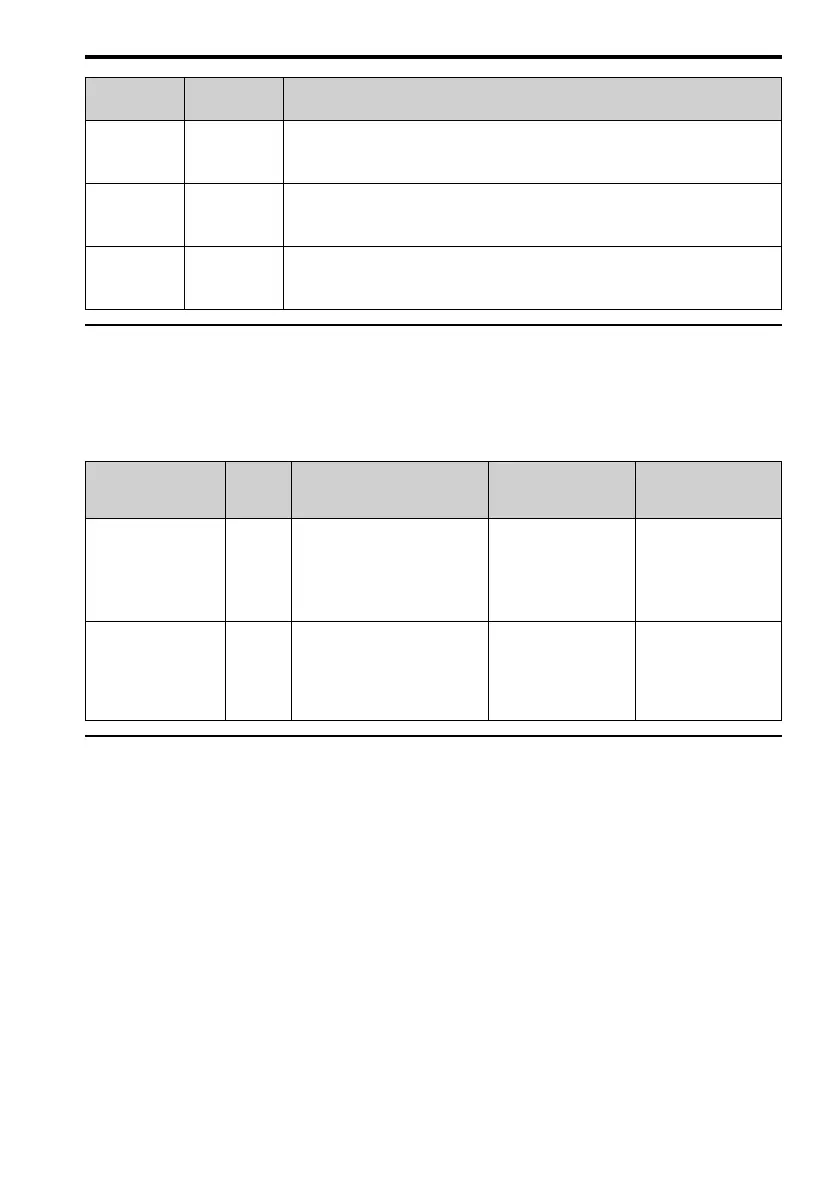

Control

Methods

A1-02 Main Applications

V/f 0

• Use for main variable-speed applications, especially when you operate more than

one motor with one drive.

• Use also when you do not have sufficient data to set the motor parameters.

OLV

2

(Default)

• Main Applications of Variable Speed Control

• Use for applications in which high-precision and high performance are necessary

and you do not use speed feedback.

EZOLV 8

• Main Applications of Variable Speed Control

• Use for applications in which high-precision and high performance are not

necessary and you do not use speed feedback.

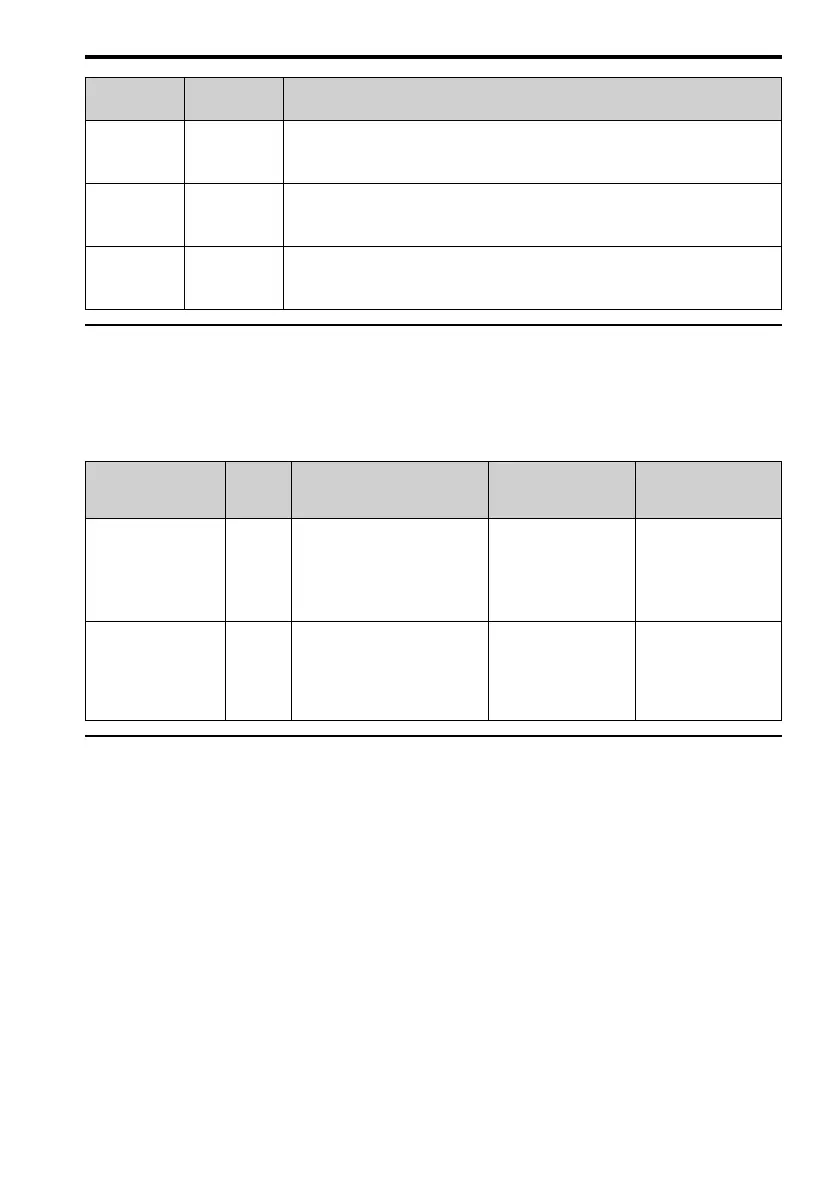

◆ Drive Duty Modes

The drive has two duty modes from which to select for the application: Heavy Duty (HD) and

Normal Duty (ND).

Refer to Table 12.1 for information about the differences between HD and ND ratings.

Table 12.1 Drive Duty Modes

Duty Rating

C6-01

Setting

Application

Default Carrier

Frequency

Overload Tolerance

(oL2 [Drive

Overload])

Heavy Duty Rating

(HD)

0

• Extruder

• Conveyor

• Cranes

• Constant torque or high

overload capacity

Determined by o2-04,

A1-02

150% of the rated

output current for 60

seconds The permitted

frequency of overload is

one time each 10

minutes.

Normal Duty Rating

(ND)

1

• Fan

• Pump

• Blower

• Variable speed control

Determined by o2-04,

A1-02

110% of the rated

output current for 60

seconds The permitted

frequency of overload is

one time each 10

minutes.

◆ Auto-Tuning for Induction Motors

This section gives information about Auto-Tuning for induction motors. Set motor parameters

E1-xx and E2-xx (or, for motor 2, E3-xx and E4-xx) for Auto-Tuning.

Note:

Do Stationary Auto-Tuning if you cannot do Rotational Auto-Tuning. There can be large differences between the

measured results and the motor characteristics when Auto-Tuning is complete. Examine the parameters for the

measured motor characteristics after you do Stationary Auto-Tuning.

Loading...

Loading...