YL9111 Binary Pump

Chapter 5. Maintenance

In the event that problem occurs or it is necessary to change part due to wear of seal in using YL9111

Binary pump, perform maintenance for instrument by referring to the following items.

5-1. Caution

L9111

In order to protect instrument, take care for the following items in using it.

1) After using solvent with sediment such as buffer solution, replace solvent with pure water at first

and then methanol or iso-propanol and make it flow for 30 minutes using each solvent at

1.0ml/min flow rate.

2) Do not use solvent to corrode stainless steel material that is less than pH 2.3.

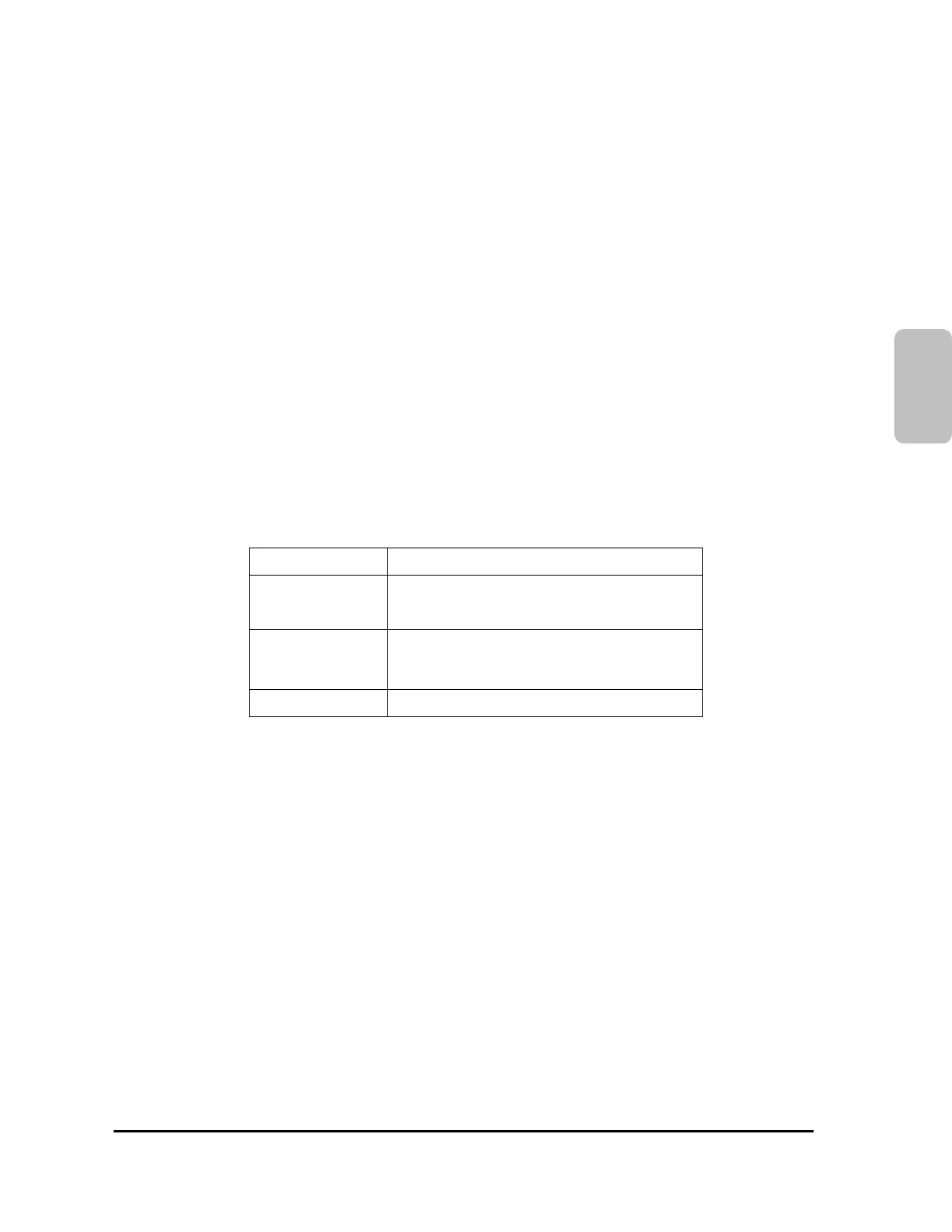

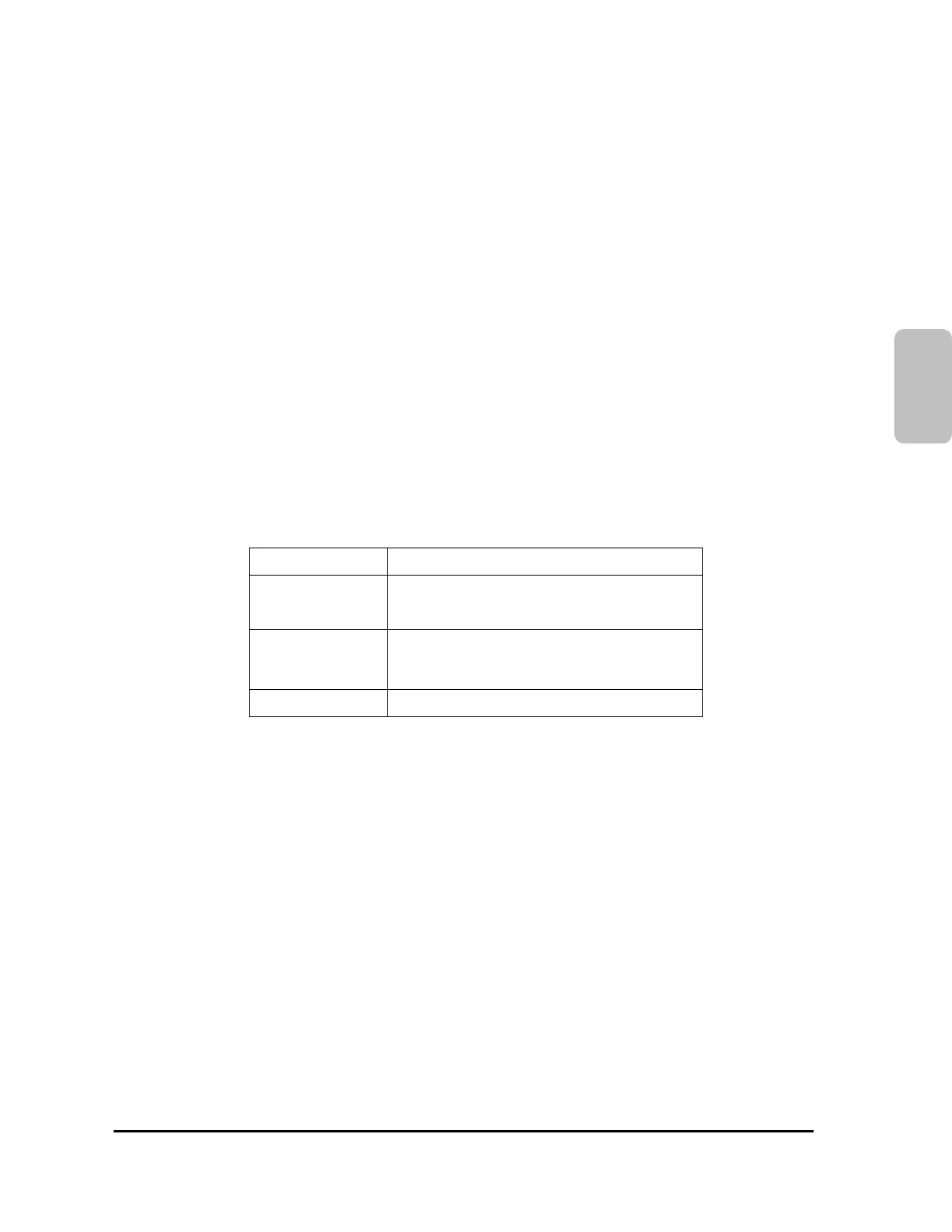

Material Solvents to avoid

PEEK

Carbon Tetrachloride, Liquid Chlorine

Methylene Chloride, Tetrahydrofuran

Teflon(PTFE) Dimethyl Formamide, Diethylamine

SS316 Phosphoric Acid(Conc, Rm Temp)

3) Do not install instrument where corrosive gas is generated or where there is carpet on floor.

4) Do not change flow rate rapidly in order to prevent from wrong operation of instrument, damage

to column and damage to damper.

5) Do not operate instrument with excessive force.

5-2. Replacement of high pressure seal

If instrument is used for long time, high pressure seal is worn out to produce leakage of solution. In this

case, after replacing it with new seal, it is necessary to condition it in order to make seal be used for long

time at high pressure. Change and condition high pressure seal in the following method. In case

instrument is used for the first time after purchasing, it is desired to perform training and it is better to

change all seals of both head when change seal due to long use. Leaked solvent flows out through

washing port.

23

Loading...

Loading...