4 Repair

4.4.3. Replacement of complete upper arm

3HAC026048-001 Revision: A122

© Copyright 2006-2008 ABB. All rights reserved.

16. Fit the other tapered roller bearing and

lubricated lock nut to the opposite side of the

upper arm.

Use the extended KM nut and tighten the lock

nut with 55 Nm, then untighten and retighten

with 35 Nm.

Art. no. is specified in Required

equipment on page 116.

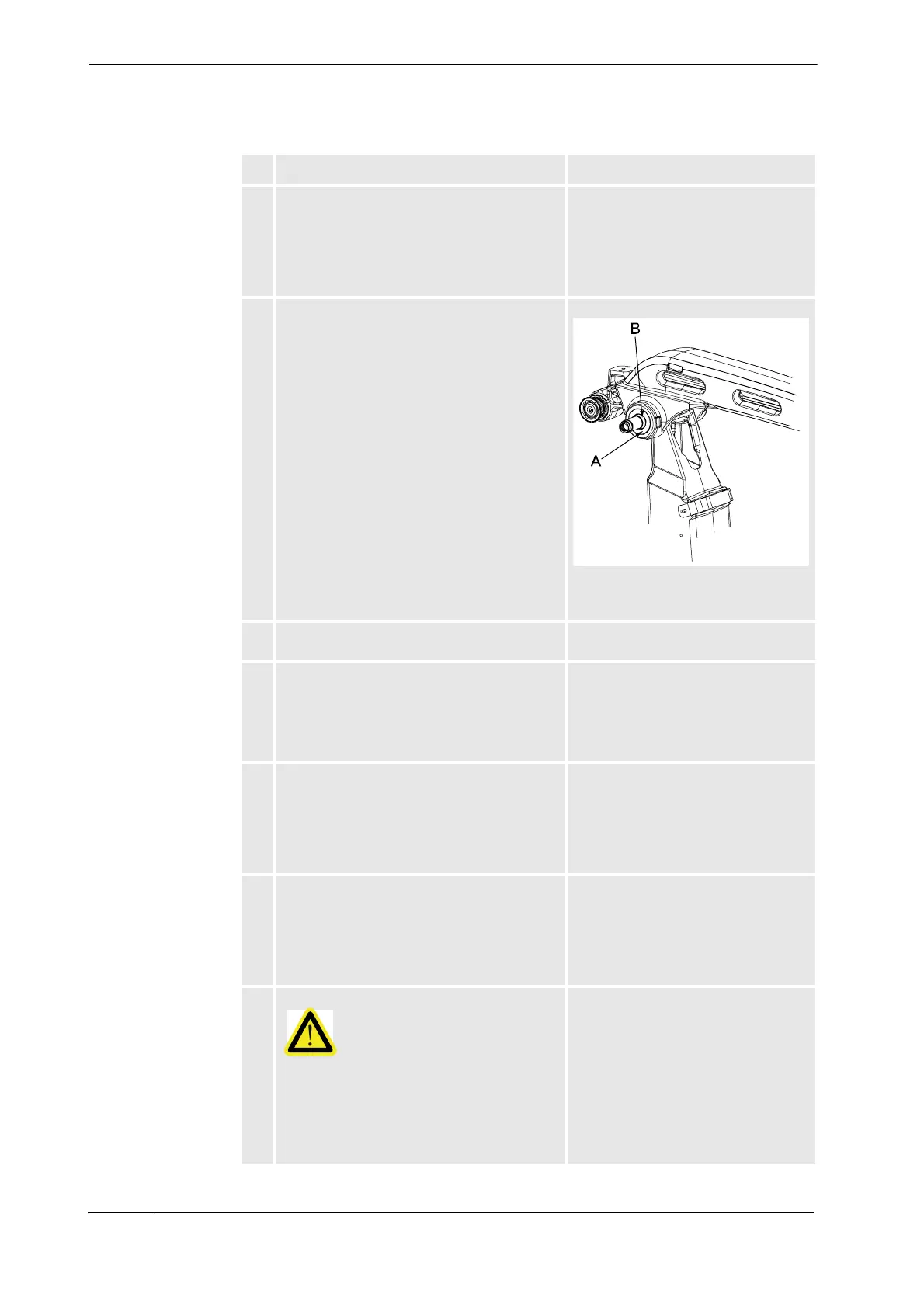

17. Fit the distance and the radial sealing to the

shaft end by hand.

Note! Make sure to fit the radial sealing with

the flat side outwards!

xx0600002607

A. Radial sealing

B. Distance

18. Refit the parallel bar. Detailed in section Refitting, parallel

bar on page 140.

19. Refit the linkage. Detailed in sections:

• Refitting, link on page 132

• Refitting, upper rod on page

125

• Refitting, lower rod on page 127

20. Run the cable unit inside the upper arm.

Reconnect all connectors and refit all

brackets.

Cable run, connectors and brackets

are shown in the figure Location of

cable unit, axis 6 on page 96.

The refitting is further detailed in

section Refitting, cable unit axis 6 on

page 99.

21. Recalibrate the robot. Calibration is detailed in a separate

calibration manual, enclosed with the

calibration tools.

General calibration information is

included in section Calibration

information on page 175.

22.

-

Danger!

Make sure all safety requirements are met

when performing the first test run. These are

further detailed in section DANGER - First test

run may cause injury or damage! on page 32.

Action Note/Illustration

Continued

Loading...

Loading...