3 Maintenance

3.2.2. Maintenance schedule

773HAC026048-001 Revision: A

© Copyright 2006-2008 ABB. All rights reserved.

3.2.2. Maintenance schedule

General

The robot must be maintained regularly to ensure proper function. The maintenance activities

and intervals are specified in the table below.

Non-predictable situations also give rise to inspections of the robot. Any damages must be

attended to immediately!

The inspection intervals do not specify the life of each component.

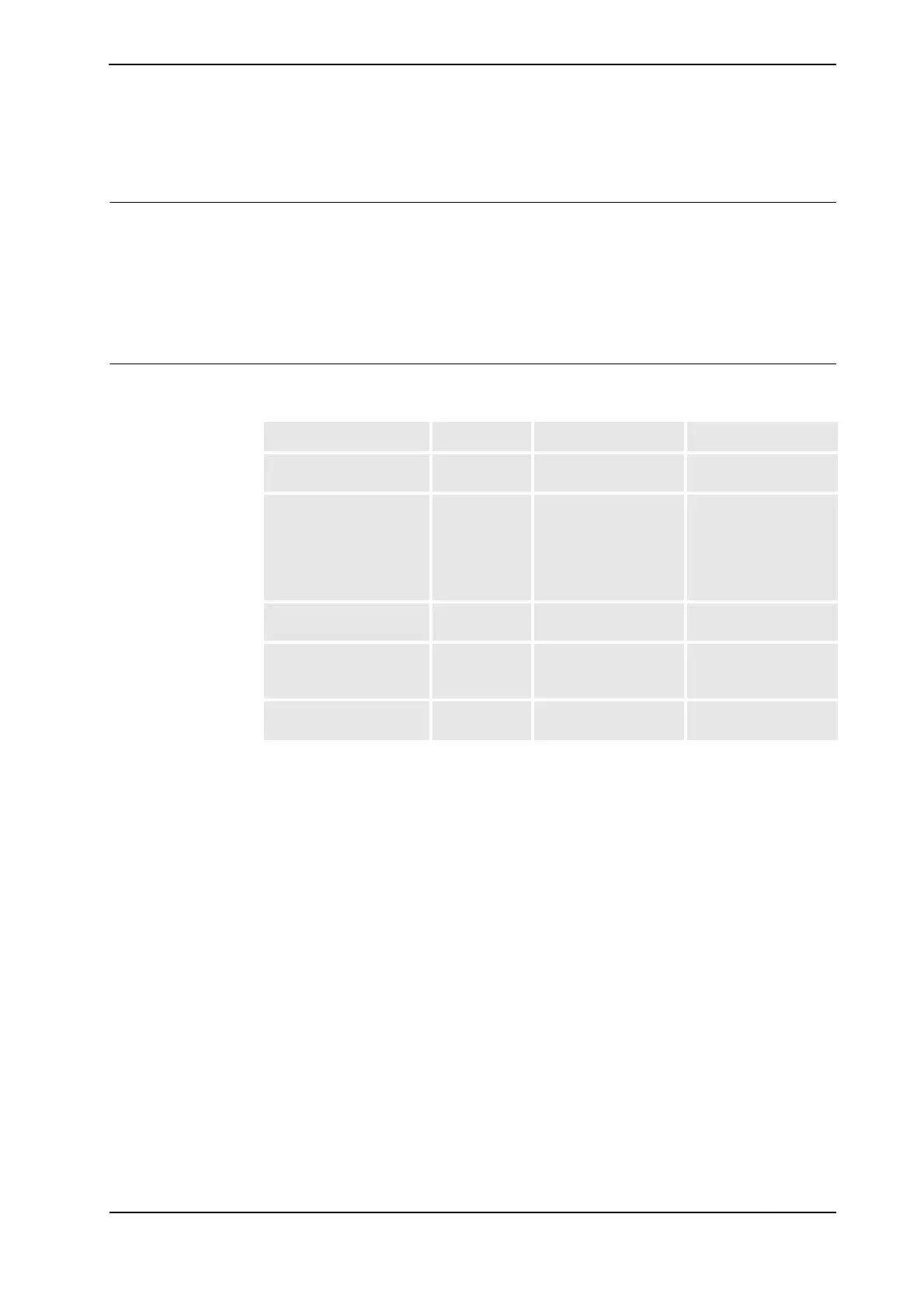

Activities and intervals, standard equipment

The table below specifies the required maintenance activities and intervals and also refers to

the section where performing the activity is detailed.

1. The battery is used as a back-up when the robot system is switched off. Therefore, the

life of a lithium battery depends on how frequently the power to the system is switched

off and also if the environment temperature is higher than recommended operating

temperature. The life varies from 12 - 36 mths, depending on current conditions. An

alert is given on the TPU or the FlexPendant when the battery is nearly discharged and

it must then be replaced within a month.

Maintenance activity Interval Note Detailed in section:

Oil change in gearboxes,

axes 1,2, 3

40,000 h Lubricated for life.

Maintenance free units.

Oil change in wrist unit - No preventive

maintenance in terms

of changing the gear oil

is needed when

gearbox is lubricated

with Shell Tivela S 150.

Oil change, gearbox

axis 6 (wrist unit) on

page 81.

Replacement of back-up

battery for SMB unit

12-36 mths

1

Replacement of SMB

battery on page 83.

Inspection of all signal

cabling in lower and

upper arm

36 mths Replace if required.

Replacement of

mechanical stop axis 1

60 mths Replace if bent.

Loading...

Loading...