4 Repair

4.7.2. Replacement of motor, axis 2

3HAC026048-001 Revision: A160

© Copyright 2006-2008 ABB. All rights reserved.

13. Tighten the four attachment screws. 4 pcs. Tightening torque: 23 Nm.

14. Perform a leak-down test. Detailed in section Performing a

leak-down test on page 86.

15. Fill the gearbox with oil. Type and amount of oil is specified in

section Oil in gearboxes on page 80.

16. Refit the connection box and secure with the

three attachment screws and plain washers.

Make sure that the gasket is fitted properly!

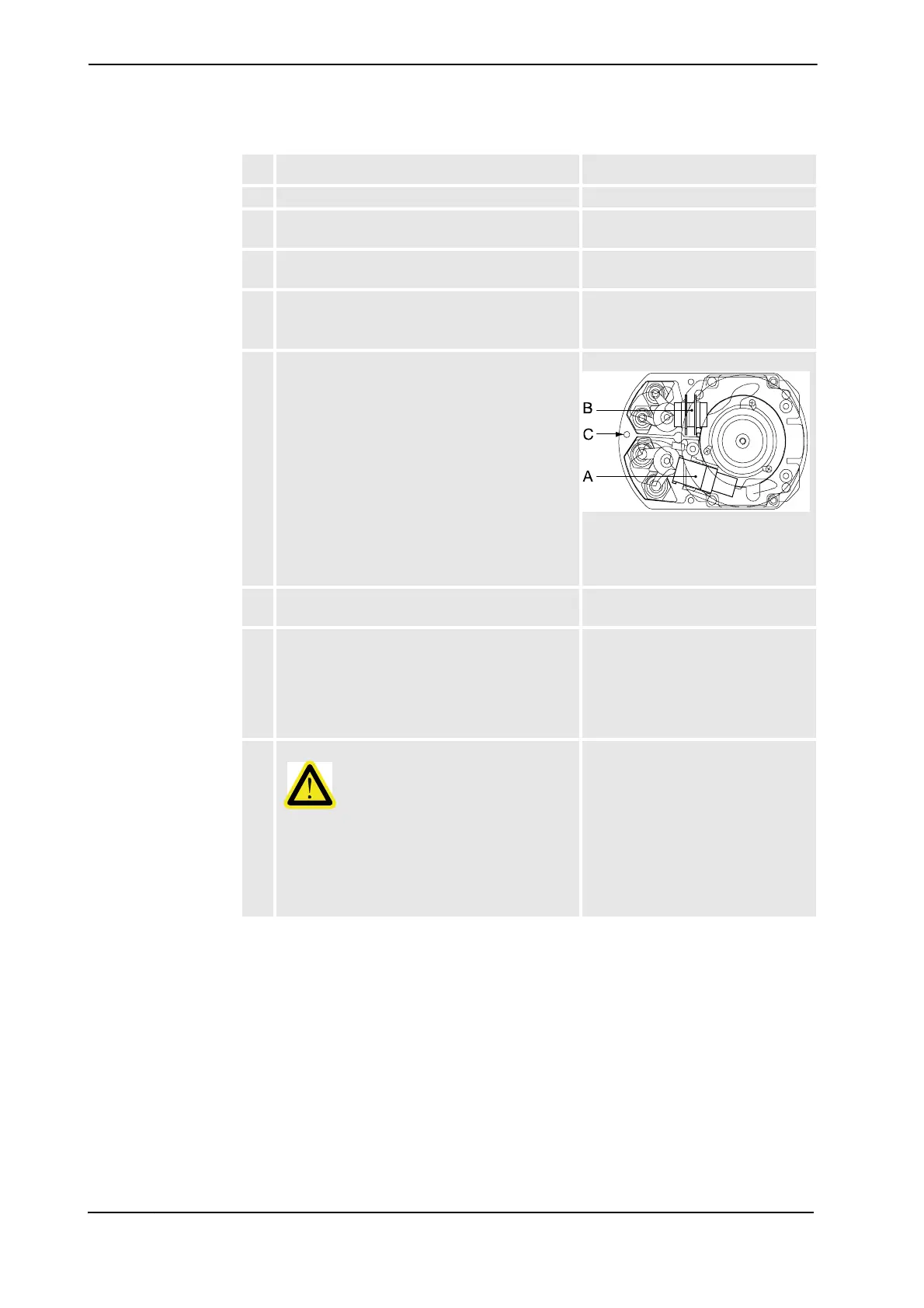

Shown in the figure Location of

motor, axis 2 on page 156.

17. Reconnect connectors R3.MP2 and R3.FB2.

xx0200000401

•A: R3.MP2

•B: R3.FB2

• C: Connection box

18. Refit the cover of the connection box. Shown in the figure Location of

motor, axis 2 on page 156.

19. Recalibrate the robot. Calibration is detailed in a separate

calibration manual, enclosed with the

calibration tools.

General calibration information is

included in section Calibration

information on page 175.

20.

-

Danger!

Make sure all safety requirements are met when

performing the first test run. These are further

detailed in section DANGER - First test run may

cause injury or damage! on page 32.

Action Note/Illustration

Continued

Loading...

Loading...