Installation and Commissioning On-Site Installation

Product Manual IRB 640 9

2.2 Assembling the robot

2.2.1 Manipulator

The three support points of the manipulator foot shall be mounted on three flat surfaces

with a flatness within the specification. Use shims if necessary. The rest of the surface

must be flat within ± 2 mm. Footprint diagram, see Figure 5. Floor mounted models

can be tilted max. 5

o

.

The levelness requirement for the surface is as follows:

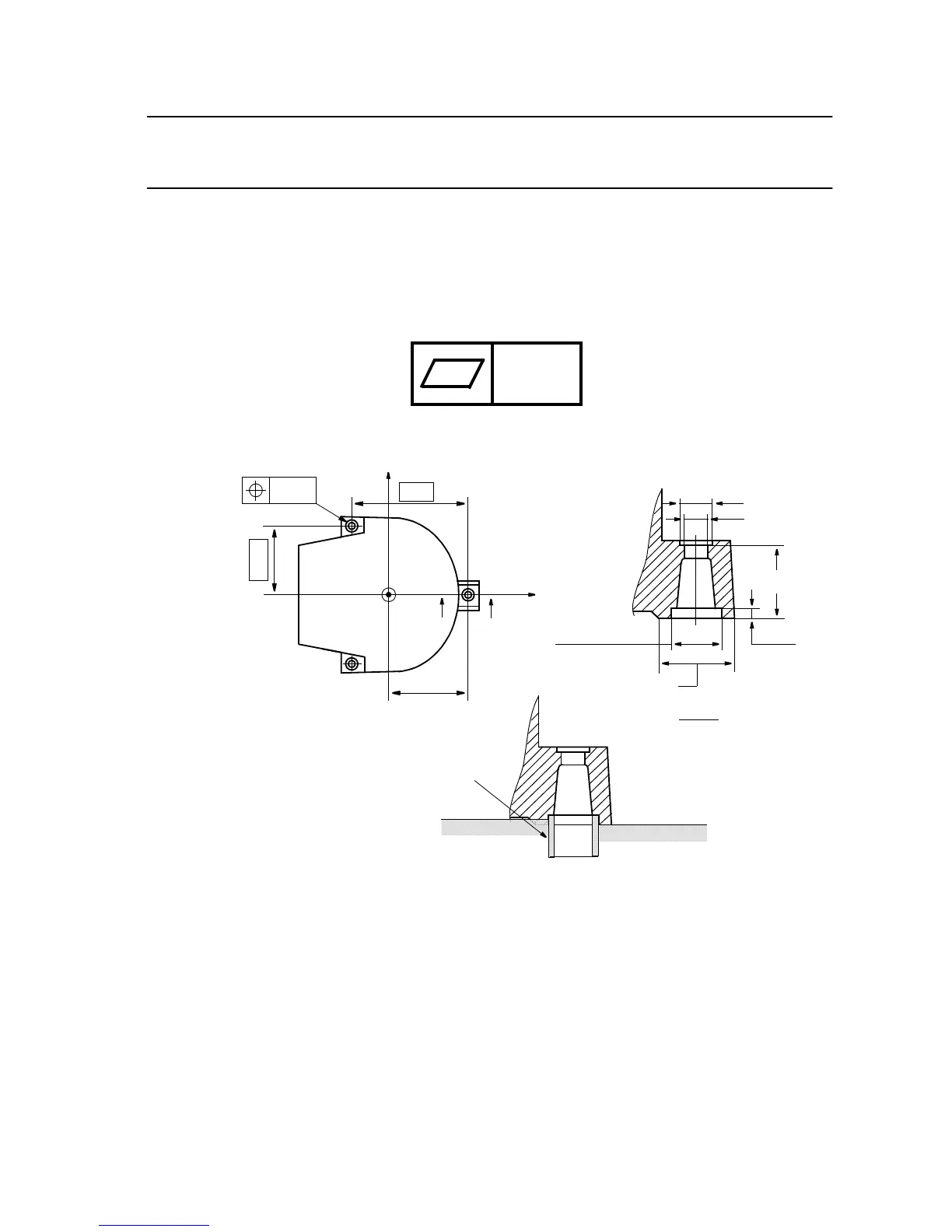

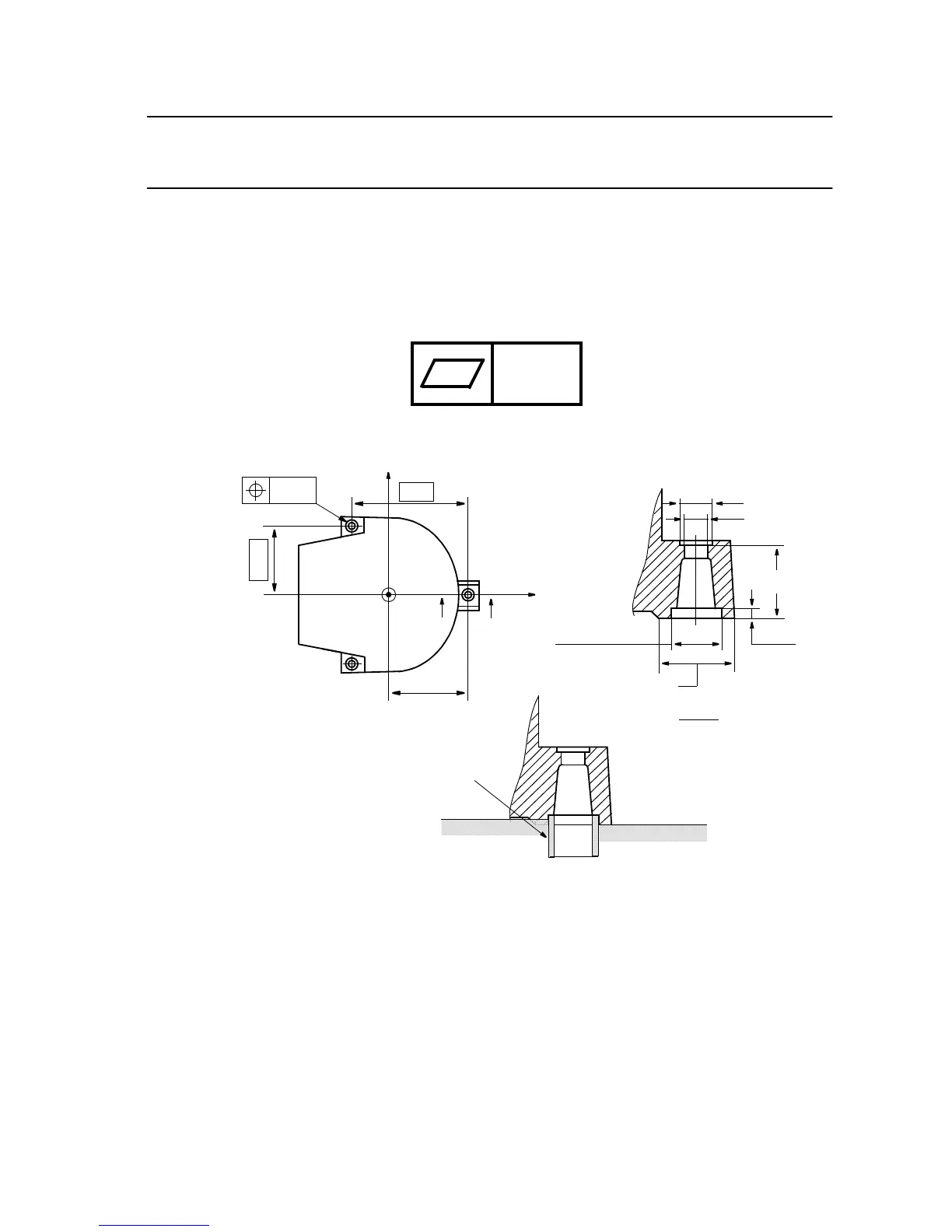

Figure 5 Bolting down the manipulator (dimensions in mm).

The manipulator is fixed with three M30 bolts, tightened alternately.

Suitable bolts: M30x160 8.8 Socket screw with washer

Tightening torque: 1000 Nm

Two guide sleeves can be added to two of the bolt holes, to allow the same manipulator

to be re-mounted without program adjustment (see Figure 5).

When bolting a mounting plate or frame to a concrete floor, follow the general

instructions for expansion-shell bolts. The screw joint must be able to withstand the

stress loads defined in Chapter 2.3 Stress forces .

0.5

D=64 H9 (3x)

Support surface D=85 (3x)

A

0.2

720

480±0.1

A

∅

415.7

D=32(3x)

D=48(3x)

A - A

X

Y

Z

100 ±0,5

15

+2

0

Guide sleeve

Loading...

Loading...