LTP51 H EN Service instructions

© Atlas Copco Industrial Technique AB - 9836 938172 72

13

Service instructions

Service instructions

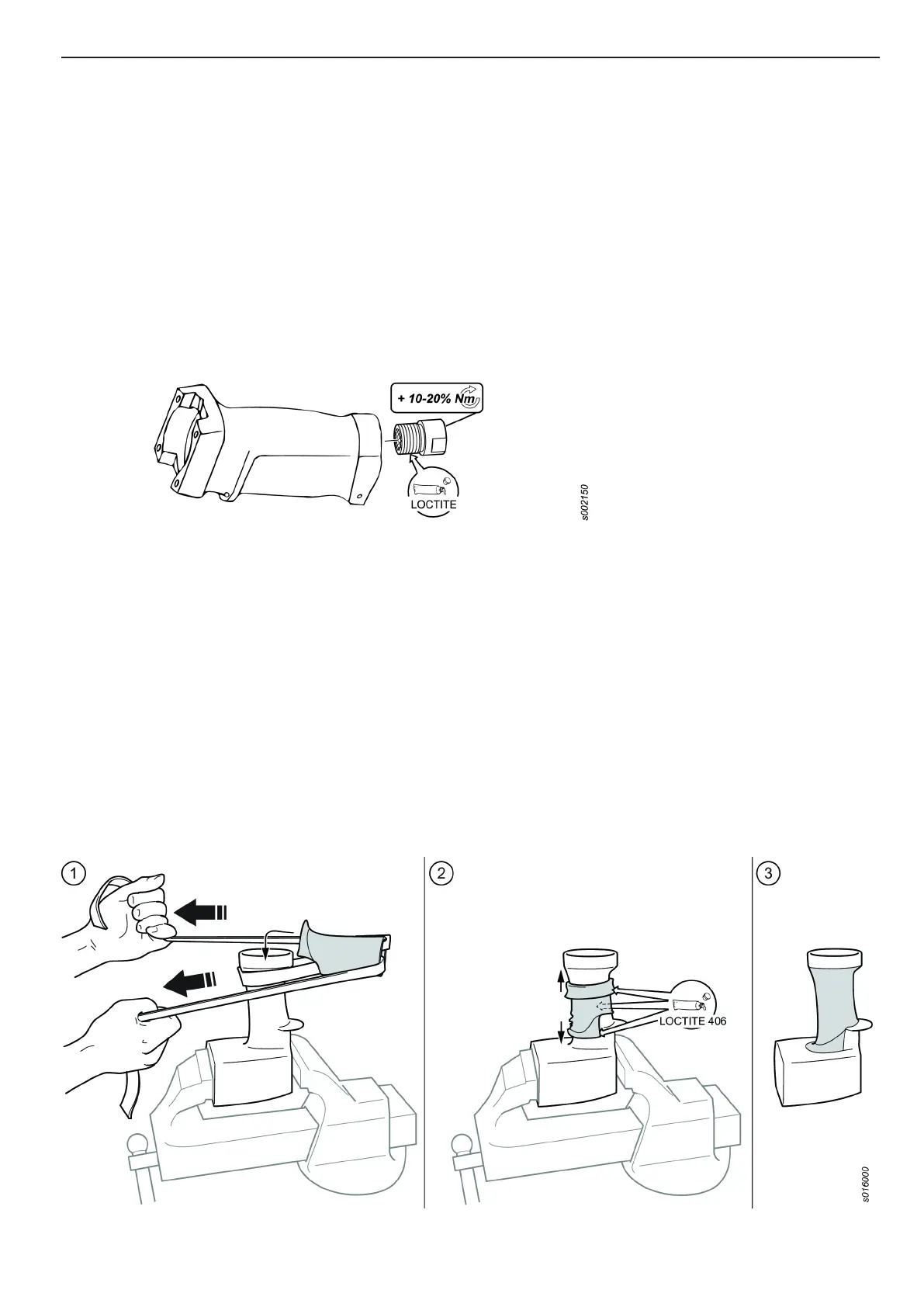

Tightening of threaded connections

The tightening torques indicated in the spare parts list are established to achieve

the correct clamping force and to prevent the parts from coming loose. When

serviced these parts must be able to open up without being destroyed. In special

circumstances (depending on application and usage) the parts may however

come loose after some time of operation. In such cases the torque could be in-

creased 10-20% and if necessary some type of low or medium threadlocking

fluid could also be applied.

Example

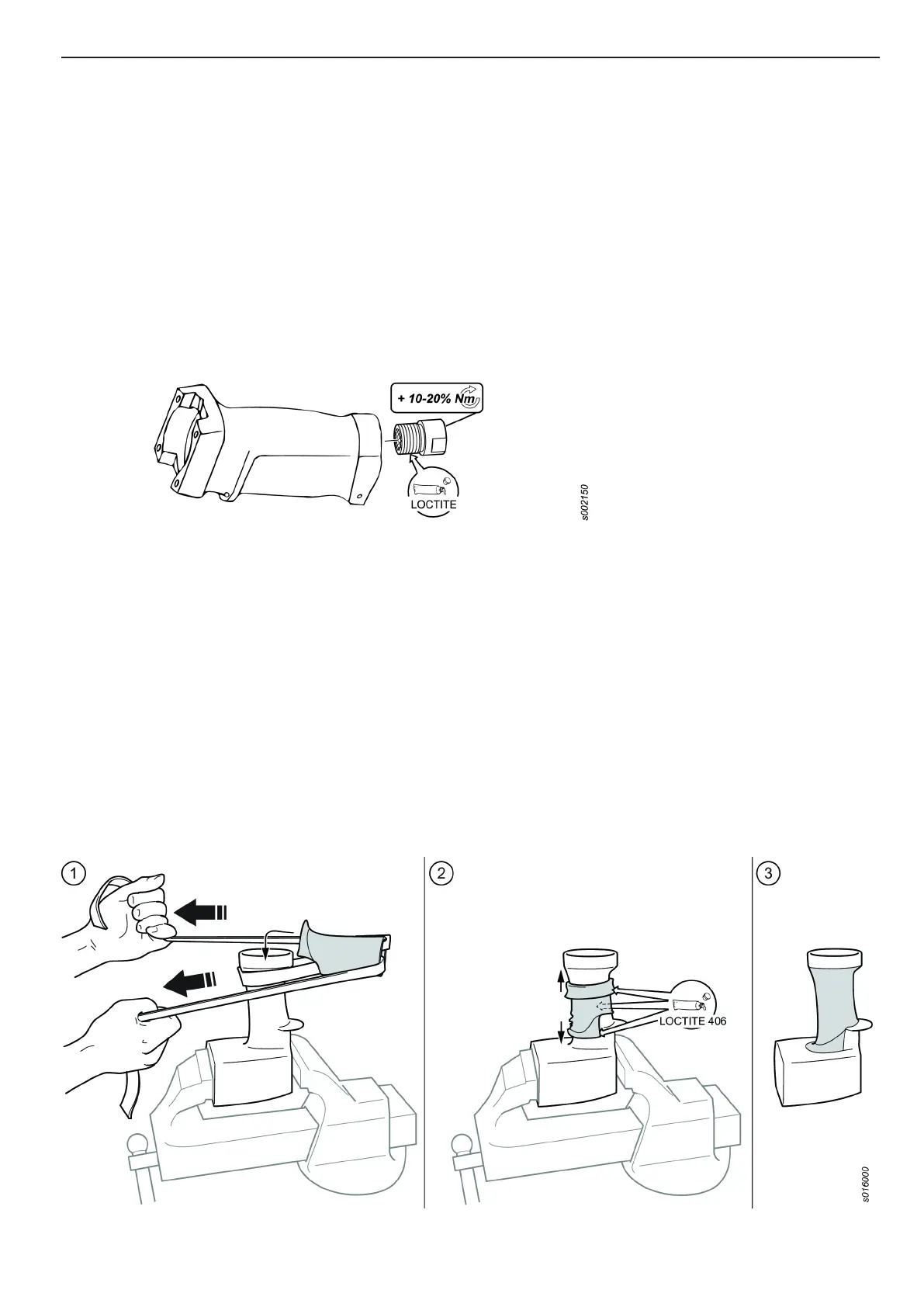

Assembly

Remove silencer and air nipple. Then completely remove the old Rubber cover.

Fix the Motor casing in a vice. To easy the assembly put some soap-water mix-

ture on the new Rubber cover ends. Make a loop of a heawy duty strap and then

put the loop of strap through the Rubber cover and then around the Handle, see

illustration 1 below. Pull on strap until Rubber cover is completely over the

lower part of handle.

Gluing

When cover is in correct position clean the ends of cover from soap. Then care-

fully apply glue (Loctite 406) on the inside around edges and in the middle of

cover, see illustration 2 below. It is especially important that the surface near

the trigger is carefully coated with glue. Press Rubber cover so it fits nice and

thight, see illustration 3 below.

Loading...

Loading...