35Bend-Tech Dragon A150

Troubleshooting Guide

Engraver

05

05

Engraver

Engraver

The Engraver on the Dragon A150 is powered by a single air source. The air pressure to

the Engraver is controlled by a regulator located on top of the Head of the machine. Proper

performance of the Engraver is dependent on air pressure. Bend-Tech recommends setting

initial air pressure to 70-80 PSI.

When troubleshooting the Engraver, ensure there are no leaks at air line connections. Ensure

air lines are not cracked, kinked or broken.

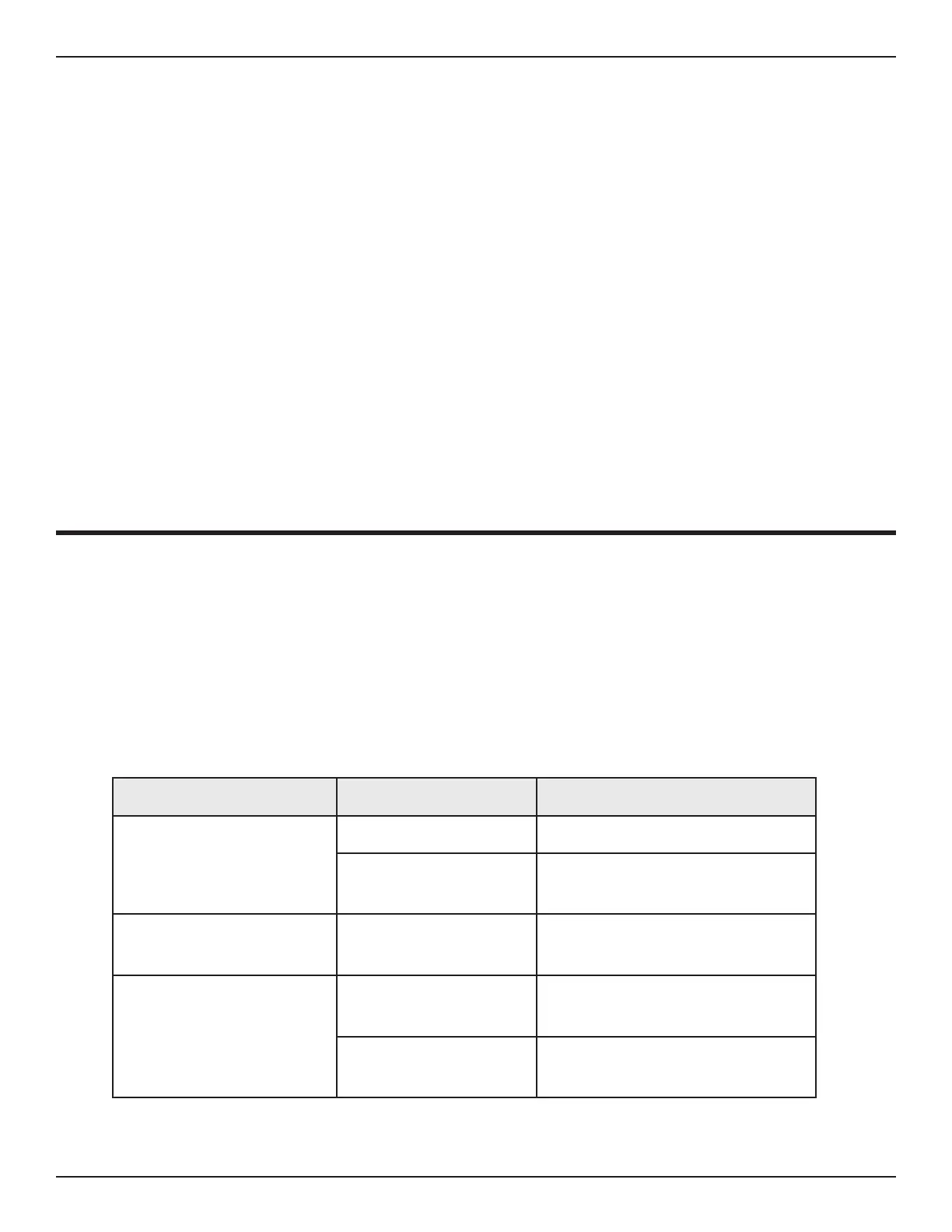

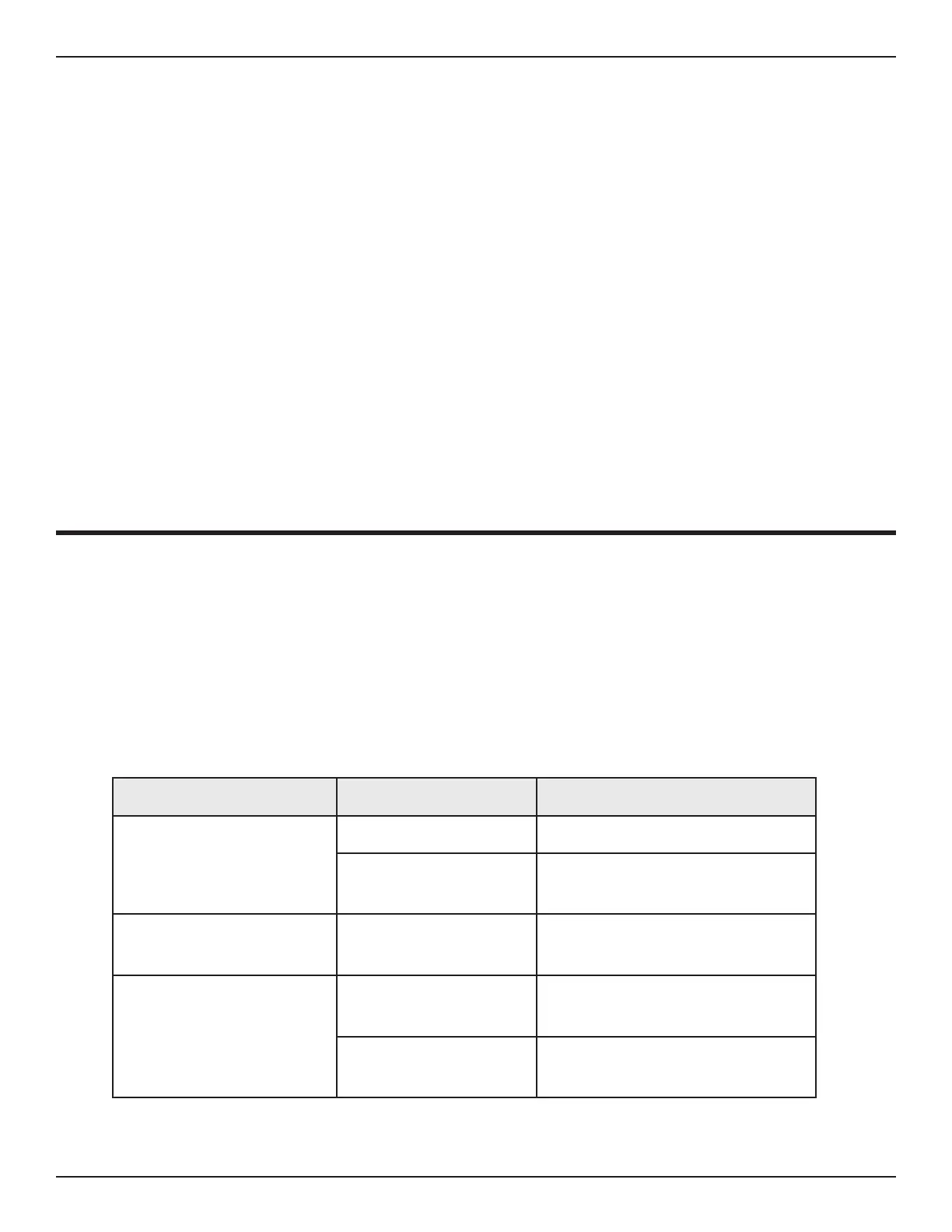

Symptom Cause Corrective Action

Engraver air cylinder not

extending all the way

Air pressure too low Increase air pressure to air cylinder

Too much friction in

actuation cylinder

Lubricate the engraver actuation

cylinder with penetrating oil

Engraver sticking in air

cylinder

Too much friction in the

actuation cylinder

Clean engraver actuation cylinder.

Lubricate the engraver actuation

cylinder with penetrating oil

Engraving too light or

engraver digging into

material

Improper air pressure to air

cylinder

Increase or reduce air pressure to

achieve proper engraver actuation

Improper air pressure to

engraver

Increase air pressure to keep engraver

from digging into, or hanging up on,

material

Loading...

Loading...