61Bend-Tech Dragon A150

Troubleshooting Guide

Control Box

13

Remove the Control Box cover and observe the Gecko Drive status lights next to the black

power cord. If the light is red, check Mach3. Click the Diagnostics tab. If Mach indicates M1++

error, the Operator can conclude the Gecko Drive has failed.

Adjusting the Gecko Drive

In some instances the motors on the

Dragon A150 may not be operating as

smoothly as desired. It is possible to

adjust the Gecko Drive and achieve

smoother and quieter motor operation. If

the Dragon A150 is working properly it is

not necessary to adjust the Gecko Drive.

The Gecko Drive is pre-adjusted with

the screws inside the trim pots set at 11

o’clock. The screws have a travel from

the 8 o’clock position to the 4 o’clock

position. If the motors on the machine

are not operating properly Bend-Tech

recommends adjusting the screws to the

8 o’clock position.

Tools Required

•

• Phillips screwdriver (small)

1.

2.

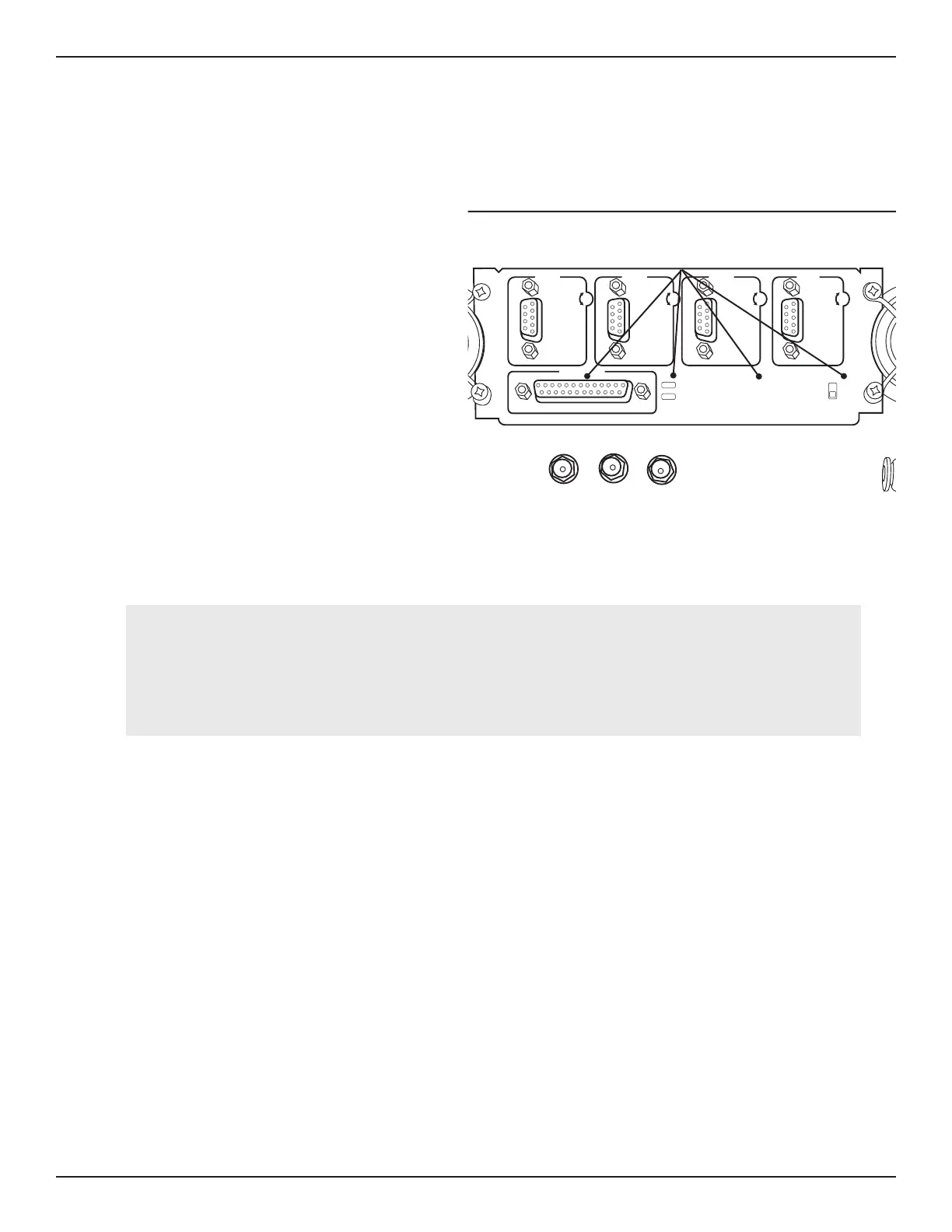

3. Locate the plate with the series of inputs where the Axis cables attach to the Control Box.

4. Using a small Phillips screwdriver, turn each screw counterclockwise until it reaches the 8

o’clock position. The screws are fragile, use care when turning them. Do not over turn the

screws.

Replacing the Gecko Drive

If the Gecko Drive has become unresponsive it is possible it may have failed. Replacing the

Gecko Drive requires accessing the Control Box as outlined earlier in this section. Once the

Operator has access to the Control Box, replacement of the Gecko Drive can be performed.

X Y Z

PARALLEL PORT

POWER

ON

OFF

CHARGE

PUMP

FAULT

X AXIS Y AXIS Z AXIS A AXIS

Trim Screws

Loading...

Loading...