51Bend-Tech Dragon A150

Troubleshooting Guide

X and Y Axis Maintenance

11

11

X and Y Axis

Maintenance

X and Y Axis Maintenance and Adjustment

operation. The machine relies on numerous set screws and adjustments regarding its

operational axes. Maintaining set screws and drive systems adjustments is critical to the

accurate operation of the machine. The Operator should ensure set screws, gears and chains

are kept in adjustment.

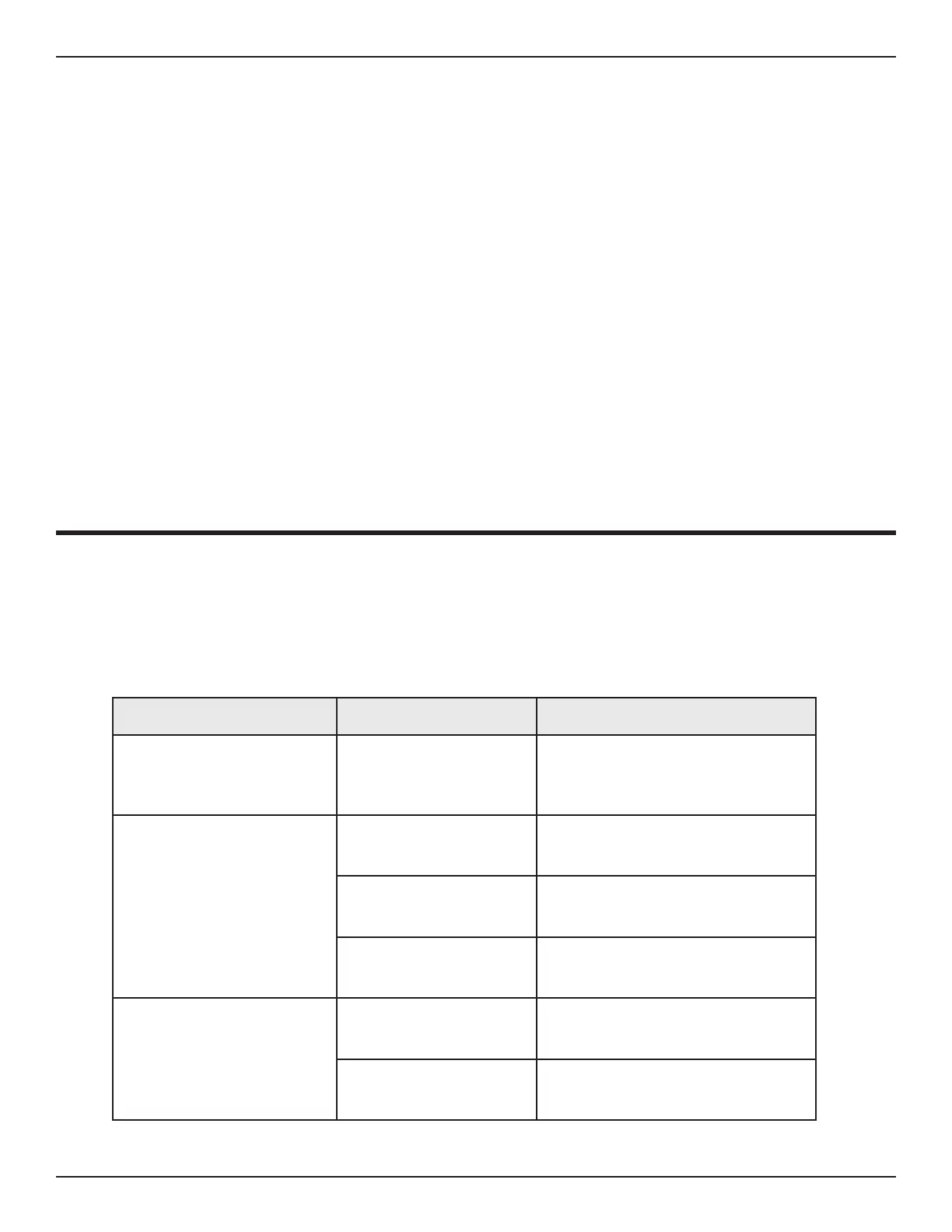

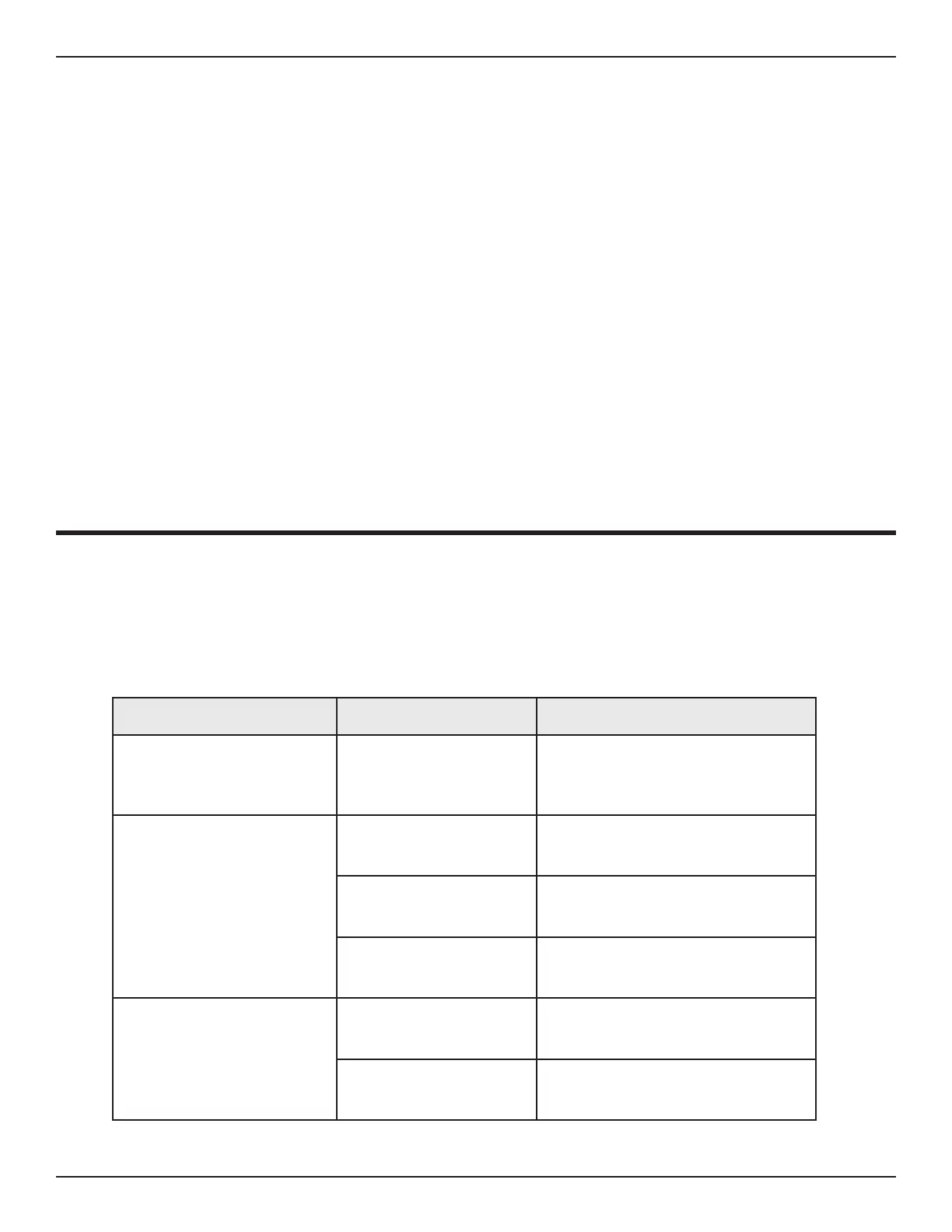

Symptom Cause Corrective Action

X chatter

Cause

X chain drive gear

Install revised X chain drive gear;

check X drive chain tension; ensure

anti-chatter kit is installed.

Y motor not holding

torque

Y drive chain tension too

tight

Adjust Y chain motor mount plate to

correct chain tension.

Material too heavy

Check material weight, ensure it is

within machine capabilities.

Gate sticking, not

functioning correctly

Check Gate, clean Gate to restore

function. If necessary, service Gate to

ensure all parts are operating properly.

Trolley not moving

smoothly along the Rail

Trolley roller system not

adjusted properly

Adjust Trolley roller system so the

Trolley has no play and travels

smoothly along the Rail.

Rail dirty

Clean and wipe down Rail, coat with

penetrating oil.

Loading...

Loading...