58 Bend-Tech Dragon A150

Troubleshooting Guide

Center Support Lift

12

Center Support Lift Air Cylinder

The Center Support Lift Air Cylinder actuates the Center Support Lift Gate to secure the

material. Ensure the Center Support Lift Air Cylinder is properly secured to the Center Support

Lift and that it’s pivot points are clean and lubricated. Ensure the air lines that supply the

leaks or kinks.

Center Support Lift Air Pressure Setting

Air pressure settings for the Center Support Lift are dependent on the operation of the

mechanism. Bend-Tech recommends a starting range of 60-80psi. The Operator may need to

adjust the air pressure to achieve optimum Center Support Lift operation.

Center Support Lift Actuation Switch

The Center Support Lift is actuated by a push-pull switch mounted on the side of the Rail. To

engage the Center Support Lift on the material the Operator is required to pull the switch out

manually. As the Trolley moves forward along the Rail during its job process, it will contact the

switch, depressing the switch to initiate the Center Support Lift to retract from the material.

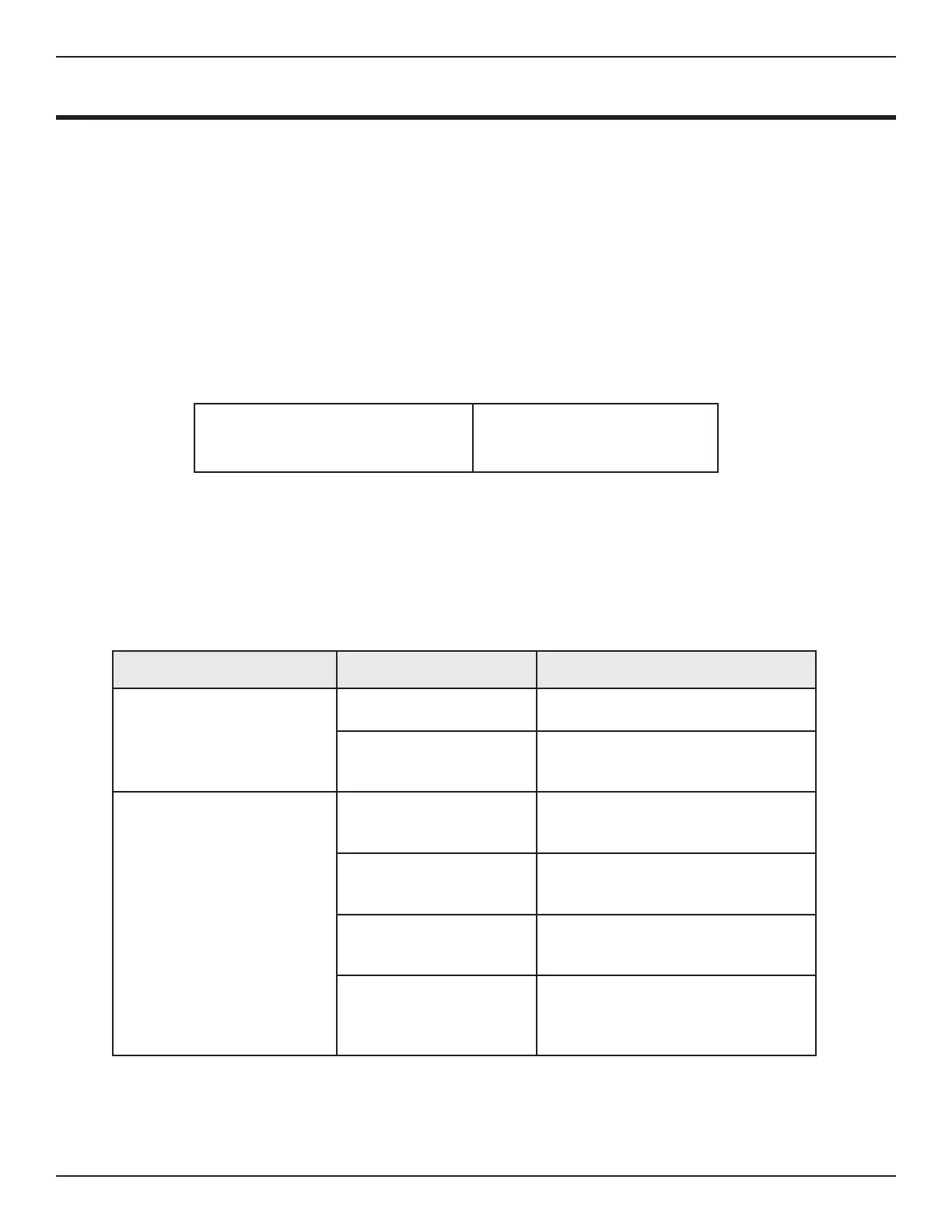

Symptom Cause Corrective Action

Center Support Lift not

engaging when switch is

pulled

Center Support Lift hinge

dirty

Clean Gate hinge, lubricate with light

oil

Air pressure incorrect/

broken or kinked air line

inspect air line connections for kinks

or leaks.

Center Support Lift not

retracting when switch

depressed

Air pressure incorrect/

broken or kinked air line

inspect air line connections for kinks

or leaks.

Trolley not depressing the

switch

Ensure bearing contact on Trolley is

engaging the switch

Center Support Lift hinge

dirty

Clean Gate hinge, lubricate with light

oil

Center Support Lift Gate

not retracting

Check Gate air cylinder for proper

operation; adjust Gate air cylinder

pressure if necessary; inspect air lines

for leaks or kinks

Center Support Lift Air

Pressure Setting

60-80PSI

Loading...

Loading...