172

Filter Drier — Replace whenever the moisture/liquid indi-

cator shows moisture in the system or when the system was

opened for service.

Liquid Line Service Valves — Use caution when

closing liquid line service valves. The expansion of a trapped

liquid can create dangerously high pressures. Remove refriger-

ant immediately from trapped sections or attach a hose from

the high side to the low side of the system to provide relief. If

equipped with a liquid line solenoid valve in the evaporator

section, it will be closed during the off-cycle. This creates the

potential for a liquid trap between the solenoid valve and a

closed service valve. Remove refrigerant immediately from the

section or attach a hose for relief.

Protective Devices

COMPRESSOR PROTECTION

Overcurrent

— Each compressor has one manual reset,

calibrated trip, magnetic circuit breaker. Do not bypass connec-

tions or increase the size of the circuit breaker to correct trou-

ble. Determine the cause and correct it before resetting the

breaker.

Overtemperature

— Each compressor has a protector to pro-

tect it against excessively high discharge gas temperatures.

Additionally, some units contain Copeland compressors

equipped with advanced scroll temperature protection (ASTP).

A label located above the terminal box identifies Copeland

Scroll compressor models that contain this technology. See

Fig. 83. Advanced scroll temperature protection is a form of in-

ternal discharge temperature protection that unloads the scroll

compressor when the internal temperature reaches approxi-

mately 300 F. At this temperature, an internal bi-metal disk

valve opens and causes the scroll elements to separate, which

stops compression. Suction and discharge pressures balance

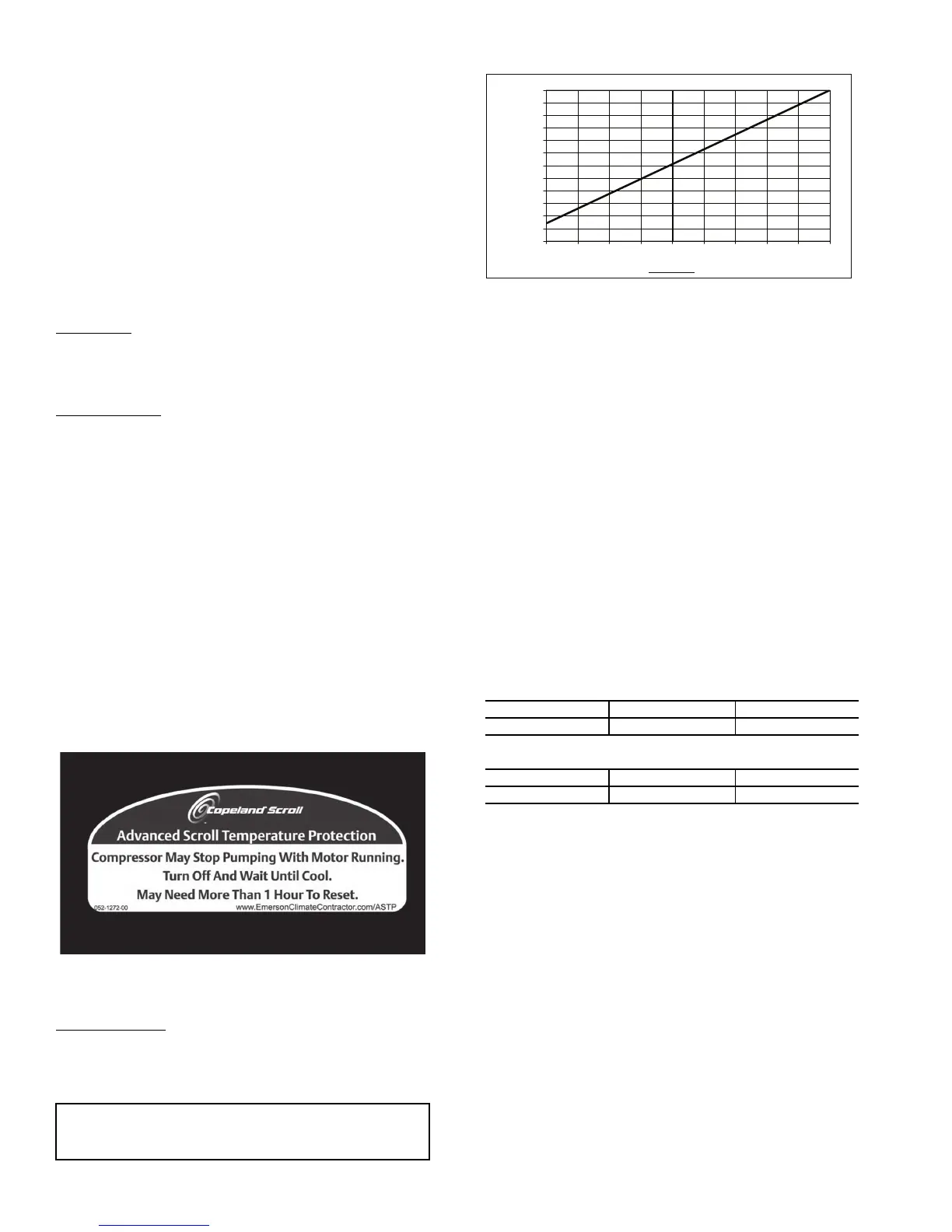

while the motor continues to run. The longer the compressor

runs unloaded, the longer it must cool before the bi-metal disk

resets. See Fig. 84.

To manually reset ASTP, the compressor should be stopped

and allowed to cool. If the compressor is not stopped, the motor

will run until the motor protector trips, which occurs up to

90 minutes later. Advanced scroll temperature protection will

reset automatically before the motor protector resets, which

may take up to 2 hours.

Crankcase Heater

— Each compressor has a crankcase heater

to prevent absorption of liquid refrigerant by oil in the crank-

case when the compressor is idle. Since 115-v power for the

crankcase heaters is drawn from the unit control circuit, main

unit power must be on for the heaters to be energized.

EVAPORATOR-FAN MOTOR PROTECTION — A manu-

al reset, calibrated trip, magnetic circuit breaker protects

against overcurrent. Do not bypass connections or increase the

size of the breaker to correct trouble. Determine the cause and

correct it before resetting the breaker.

CONDENSER-FAN MOTOR PROTECTION — Each

condenser-fan motor is internally protected against over-

temperature. They are also protected against a severe over-

current condition by manual reset, calibrated trip, magnetic cir-

cuit breakers on a common circuit. As with the circuit breakers,

do not bypass connections or increase breaker size to correct

trouble. Determine the cause and correct it before resetting the

breaker.

HIGH-PRESSURE SWITCHES — Settings for these switch-

es are shown in Tables 109 and 110. If either switch trips, that

refrigerant circuit will be automatically locked out by the con-

trols. To reset, set ALARMS

R.CUR = YES.

Table 109 — Pressure Switch Settings (psig)

Table 110 — Pressure Switch Settings (kPa)

Temperature Relief Devices — All units have tem-

perature relief devices to protect against damage from exces-

sive pressures caused by extreme high temperatures (i.e., fire).

These devices protect the high and low side.

Control Circuit, 115 V — This control circuit is protect-

ed against overcurrent by a 10-amp circuit breaker. Breaker can

be reset. If it trips, determine cause of trouble before resetting.

Control Circuit, 24 V — This control circuit is protected

against overcurrent by two 10-amp and four 3.2-amp circuit

breakers. Breakers can be reset. If a breaker trips, determine

cause of trouble before resetting.

Gas Heat (48N Only)

LIMIT SWITCHES — The maximum supply-air temperature

is controlled by a limit switch located in the gas section. The

limit is designed to trip at 100 F above the maximum tempera-

ture rise.

When the limit trips, 2 flashes occur on the IGC board. The

gas valve is de-energized. After cooling, the system will reset

and fires gas again. If four trips occur, the system shuts down

into Lockout and 4 flashes occur on the IGC board. The system

IMPORTANT: After a prolonged shutdown or service

job, energize the crankcase heaters for 24 hours before

starting the compressor.

Fig. 83 — Advanced Scroll Temperature

Protection Label

SWITCH CUTOUT CUT-IN

High 650 10 500 15

SWITCH CUTOUT CUT-IN

High 4482 69 3447 103

0

10

20

30

40

50

60

70

80

90

100

110

120

0 102030405060708090

Compressor Unloaded Run Time (Minutes)

Recommended Cooling Time

(Minutes)

*Times are approximate.

NOTE: Various factors, including high humidity, high ambient tem-

perature, and the presence of a sound blanket will increase cool-

down times.

Fig. 84 — Recommended Minimum Cool-Down

Time After Compressor is Stopped*

Loading...

Loading...