69

TEMPERING MODE — In a vent or cooling mode, the

economizer at minimum position may send extremely cold

outside air down the ductwork of the building. Therefore it

may be necessary to bring heat on to counter-effect this low

supply-air temperature. This is referred to as the tempering

mode.

Setting up the System

— The relevant set points for temper-

ing are located at the local display under Setpoints:

Operation

— First, the unit must be in a vent mode, a low cool,

or a high cool HVAC mode to be considered for a tempering

mode. Secondly, the tempering mode is only allowed when the

rooftop is configured for modulating gas, SCR electric heat, or

hydronic heating (Configuration

HEAT

HT.CF=3 or 4).

Also, if OAT is above the chosen tempering set point, temper-

ing will not be allowed. Additionally, tempering mode is

locked out if any stages of mechanical cooling are present.

If the control is configured for staged gas, modulating gas,

SCR electric heat, or hydronic heating and the control is in a

vent, low cool, or high cool HVAC mode, and the rooftop con-

trol is in a situation where the economizer must maintain a

minimum position/minimum cfm, then the evaporator dis-

charge temperature (EDT) will be monitored. If the EDT falls

below a particular trip point then tempering mode may be

called out:

HVAC mode = “Tempering Vent”

HVAC mode = “Tempering LoCool”

HVAC mode = “Tempering HiCool”

The decision making/selection process for the tempering

trip set point is as follows:

If an HVAC cool mode is in effect, then the tempering cool

point is SASP – T.CL.

If not in effect and unit is in a pre-occupied purge mode

(Operating Modes

MODE

IAQ.P=ON), then the trip point

is T.PRG.

If not in effect and unit is in an occupied mode (Operating

Modes

MODE

IAQ.P=ON), then the trip point is

TEMPVOCC.

For all other cases, the trip point is TEMPVUNC.

NOTE: The unoccupied economizer free cooling does not

qualify as a HVAC cool mode as it is an energy saving feature

and has its own OAT lockout already. The unoccupied free

cooling mode (HVAC mode = Unocc. Free Cool) will override

any unoccupied vent mode from triggering a tempering mode.

A minimum amount of time must pass before calling out

any tempering mode. In effect, the EDT must fall below the

trip point value –1° F continuously for a minimum of 2 min-

utes. Also, at the end of a mechanical cooling cycle, a 10-min-

ute delay will be enforced before considering a tempering dur-

ing vent mode in order to allow any residual cooling to dissi-

pate from the evaporator coil.

If the above conditions are met, the algorithm is free to

select the tempering mode (MODETEMP).

If a tempering mode becomes active, the modulating heat

source (staged gas, modulating gas, SCR electric heat, or hot

water) will attempt to maintain leaving-air temperature (LAT)

at the tempering set point used to trigger the tempering mode.

The technique for modulation of set point for staged gas, mod-

ulating gas, SCR electric heat, and hydronic heat is the same as

in a heat mode. More information regarding the operation of

heating can be referenced in the Heating Control section.

Recovery from a tempering mode (MODETEMP) will

occur when the EDT rises above the trip point. On any change

in HVACMODE, the tempering routine will re-assess the tem-

pering set point which may cause the control to continue or exit

tempering mode.

Static Pressure Control — Variable air volume (VAV)

air-conditioning systems must provide varying amounts of air

to the conditioned space. As air terminals downstream of the

unit modulate their flows, the unit must simply maintain con-

trol over duct static pressure in order to accommodate the

needs of the terminals, and therefore to meet the varying com-

bined airflow requirement. The unit design includes an option-

al means of accommodating this requirement. This section de-

scribes the technique by which this control takes place.

A unit intended for use in a VAV system can be equipped

with a variable frequency drive (VFD) for the supply fan. The

speed of the fan can be controlled directly by the ComfortLink

controls. A duct static pressure transducer is located in the aux-

iliary control box. The signal from the pressure sensor is re-

ceived by the RCB board and is then used in a PID control rou-

tine that outputs a fan speed to the VFD.

The PID routine periodically calculates the static pressure

error from set point. This error at any point in time is simply

the duct static pressure set point minus the measured duct stat-

ic. It is the Proportional term of the PID. The routine also cal-

culates the Integral of the error over time, and the Derivative

(rate of change) of the error. A calculated value is then used to

create an output signal used to adjust the VFD to maintain the

static pressure set point.

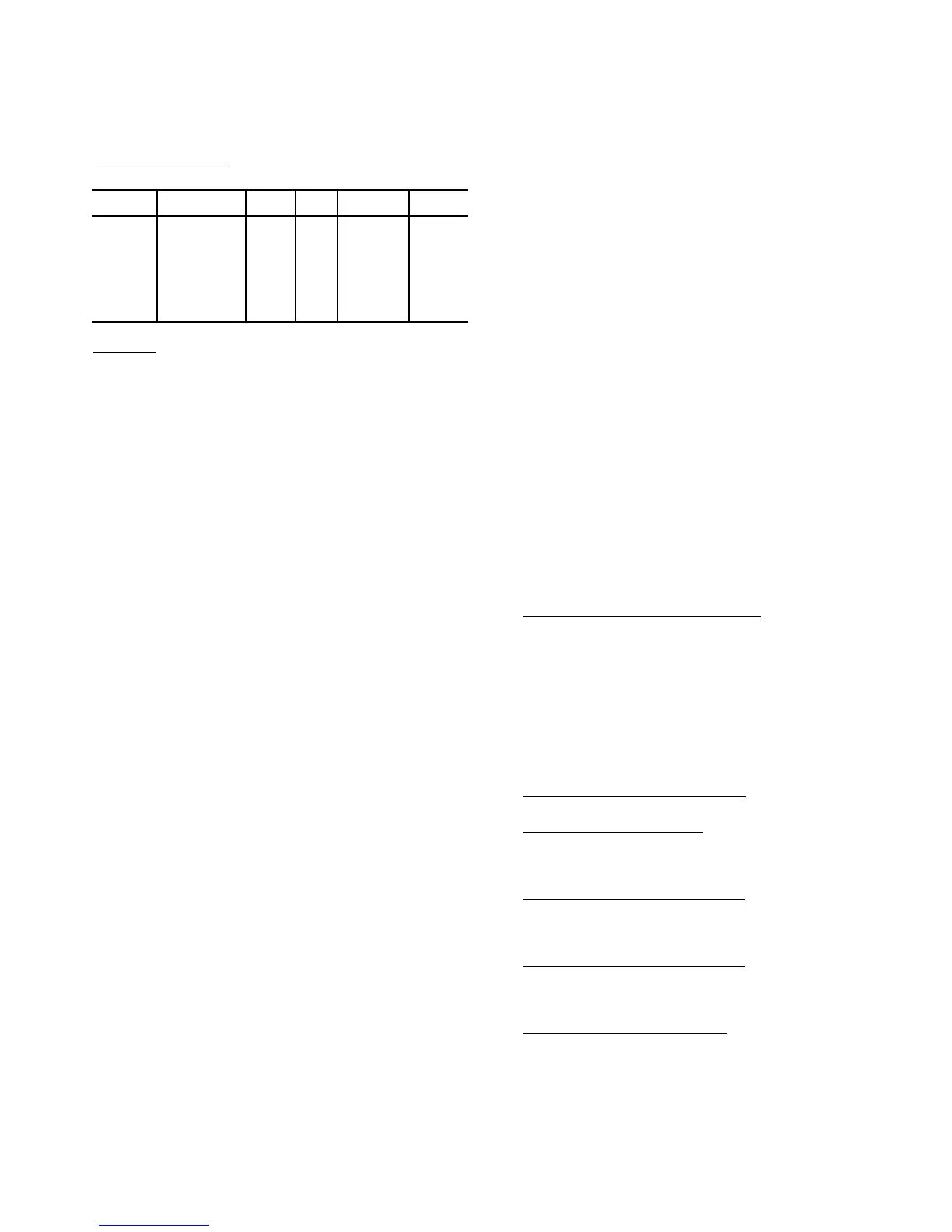

SETTING UP THE SYSTEM — Here are the options un-

der the Local Display Mode Configuration

SP. See Table 46.

Static Pressure Configuration (

SP.CF) — This variable is

used to configure the use of ComfortLink for static pressure

control. It has the following options:

• 0 (DISABLED) - No static pressure control by Com-

fortLink controls. This would be used for a constant vol-

ume (CV) application when static pressure control is not

required or for a VAV application if there will be third-

party control of the VFD. In this latter case, a suitable

means of control must be field installed.

• 1 (ENABLED) - This will enable the use of ComfortLink

controls

Staged Air Volume Control (

SP.SV) — This variable enabled

the use of a CV unit with VFD for staged air volume control.

Static Pressure Sensor (

SP.S) — This variable enables the use

of a supply duct static pressure sensor. This must be enabled to

use ComfortLink controls for static pressure control. If using a

third-party control for the VFD then this should be disabled.

Static Pressure Low Range (

SP.LO) — This is the minimum

static pressure that the sensor will measure. For most sensors

this will be 0 in. wg. ComfortLink controls will map this value

to a 4 mA sensor output.

Static Pressure High Range (

SP.HI) — This is the maximum

static pressure that the sensor will measure. Commonly this

will be 5 in. wg. The ComfortLink controls will map this value

to a 20 mA sensor output when the signal is 20 mA.

Static Pressure Set Point (

SP.SP) — This is the static pres-

sure control point. It is the point against which ComfortLink

controls compares the actual measured supply duct pressure for

determination of the error that is used for PID control. Adjust

SP.SP to the minimum value necessary for proper operation of

air terminals in the conditioned space at full load and part load.

Too high a value will cause unnecessary fan motor power con-

sumption at part load conditions and/or noise problems. Too

low a value will result in insufficient airflow.

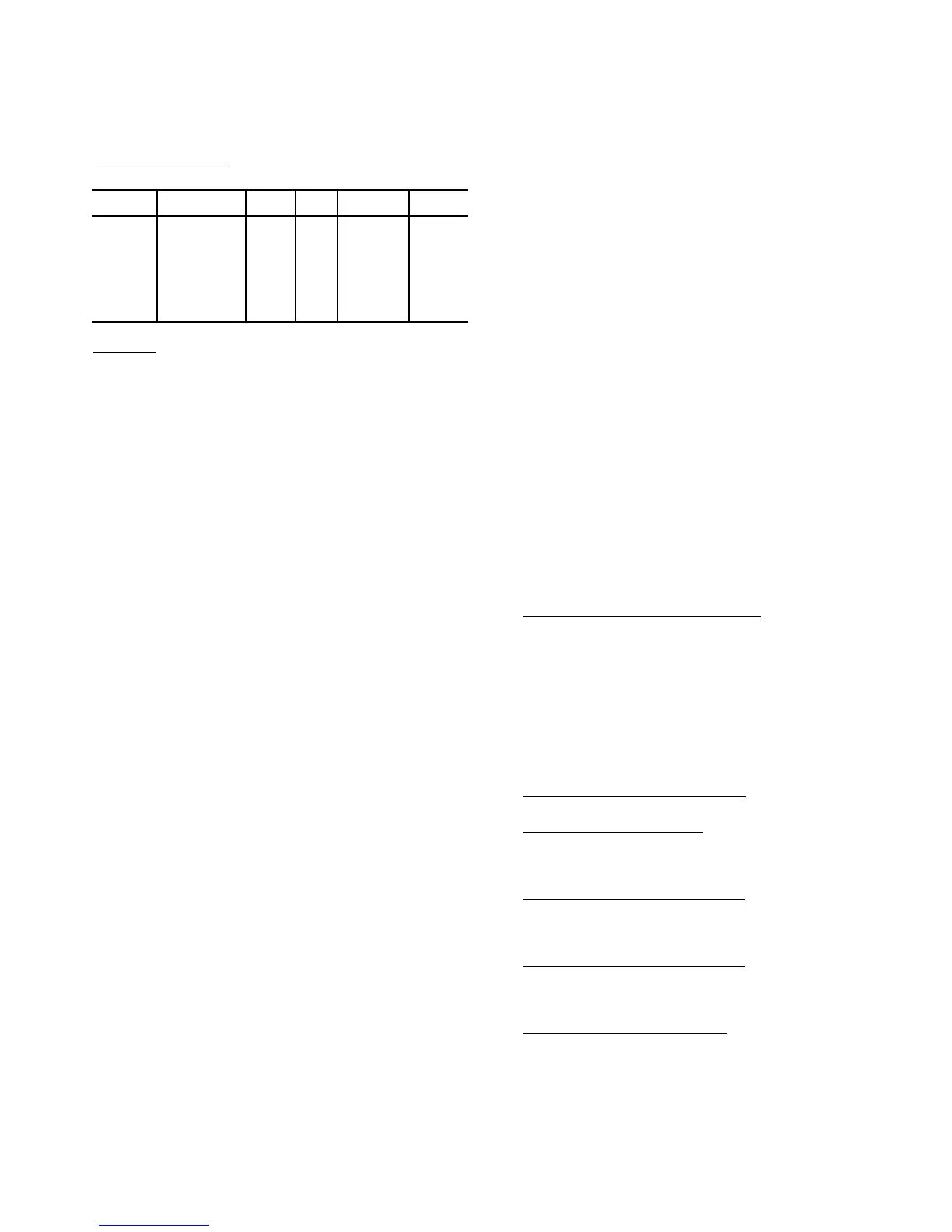

ITEM EXPANSION RANGE UNITS

CCN

POINT

DEFAULT

T.PRG

Tempering

Purge SASP

–20-80 dF TEMPPURG 50

T.CL

Tempering in

Cool Offset

5-75 ^F TEMPCOOL 5

T.V.OC

Tempering Vent

Occ SASP

–20-80 dF TEMPVOCC 65

T.V.UN

Tempering Vent

Unocc. SASP

–20-80 dF TEMPVUNC 50

Loading...

Loading...