64

Hydronic Heating Logic

If the HVAC mode is LOW HEAT:

• The control will command the supply fan on

• The control will modulate the hot water or steam coil

actuator to the heating control point (Run Sta-

tus

VIEW

HT.C.P). The heating control point for

hydronic heat is the heating supply air set point (Set-

points

SA.HT).

If the HVAC mode is HIGH HEAT:

• The control will command the supply fan on

• The control will command the hot water coil actuator to

100%.

Hydronic Heating PID Process

— If the HVAC mode is

LOW HEAT, then the hydronic heating actuator will modulate

to the heating control point (Run Status

VIEW

HT.C.P).

Control is performed with a generic PID loop where:

Error = Heating Control Point (HT.C.P) – Leaving Air Tem-

perature (LAT)

The PID terms are calculated as follows:

P = K * HW.P * error

I = K * HW.I * error + “I” last time through

D = K * HW.D * (error – error last time through)

Where K = HW.TM/60 to normalize the effect of changing the

run time rate.

NOTE: The PID values should be not be modified without

approval from Carrier.

Freeze Status Switch Logic (

Inputs

GEN.I

FRZ.S) — If

the freezestat input (FRZ) alarms, indicating that the coil is

freezing, normal heat control is overridden and the following

actions will be taken:

1. Command the hot water coil actuator to 100%.

2. Command the economizer damper to 0%.

3. Command the supply fan on.

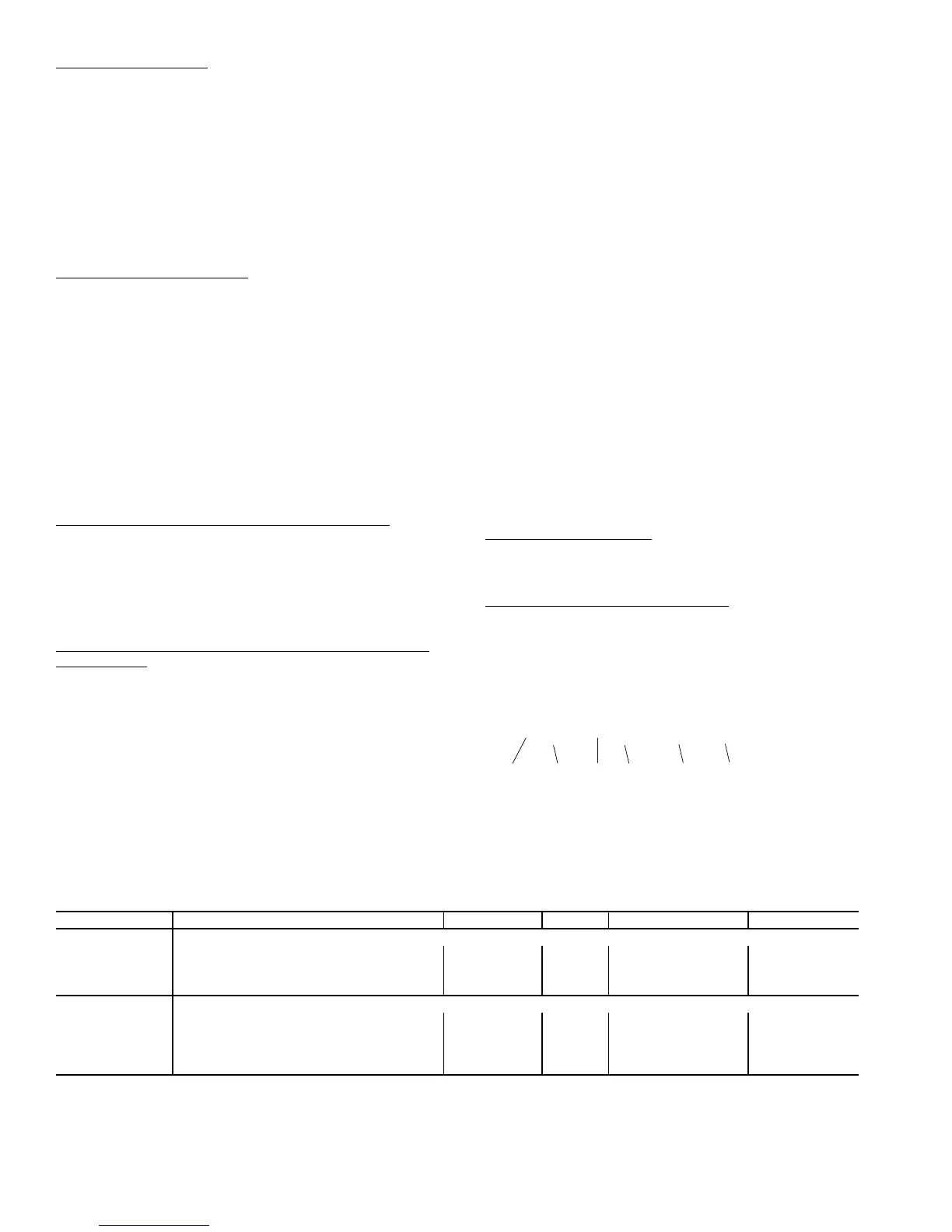

Configuring Hydronic Heat to Communicate Via Actuator

Serial Number — Every actuator used in the N Series control

system has its own unique serial number. The rooftop control

uses this serial number to communicate with the actuator.

These serial numbers are programmed at the factory and

should not need changing. Should field replacement of an actu-

ator become necessary, it will be required to configure the seri-

al numbers of the new actuator. Four individual numbers make

up this serial number and these can be programmed to match

the serial number of the actuator in its Hydronic Heating Actu-

ator Configs group, ACT.C (SN.1, SN.2, SN.3, SN.4). See

Fig. 15.

NOTE: The serial numbers for all actuators can be found

inside the control doors of the unit as well as on the actuator

itself. If an actuator is replaced in the field, it is a good idea to

remove the additional peel off serial number sticker on the

actuator and cover up the old one inside the control doors.

MODULATING GAS HEAT CONTROL (HT.CF = 3 and

HT.ST = 0, 1, 2, or 3) — As an option, the units with gas heat

can be equipped with modulating gas heat controls that will

provide infinite stages of heat capacity. This is intended for

tempering mode and tempering economizer air when in a cool-

ing mode and the dampers are at minimum vent position. Tem-

pering can also be used during a pre-occupancy purge to pre-

vent low temperature air from being delivered to the space.

Tempering for staged gas, modulating gas, and hydronic heat

will be discussed in its own section. This section will focus on

heat mode control, which ultimately is relevant to tempering,

minus the consideration of the supply air heating control point.

The modulating gas and SCR electric heat configurations

are located at the local display under Configura-

tion

HEAT

SG.CF. See Table 37.

SCR ELECTRIC HEAT CONTROL (HT.CF = 5, no req.

set HT.ST) — As an option, the units with electric heat can be

equipped with modulating SCR electric heater controls that

will provide infinite stages of heat capacity. This is intended for

tempering mode and tempering economizer air when in a cool-

ing mode and the dampers are at minimum vent position. Tem-

pering can also be used during a pre-occupancy purge to pre-

vent low temperature air from being delivered to the space.

Tempering for modulating gas, hydronic and SCR electric heat

will be discussed in its own section. This section will focus on

heat mode control, which ultimately is relevant to tempering,

minus the consideration of the supply air heating control point.

Staged Heat Type (

HT.ST) — This configuration instructs the

control as to how many stages and in what order they are

staged. Setting HT.ST = 0, 1, 2, or 3 configures the unit for

Modulating Gas Heat.

Max Cap Change per Cycle (

CAP.M) — This configura-

tion limits the maximum change in capacity per PID run time

cycle.

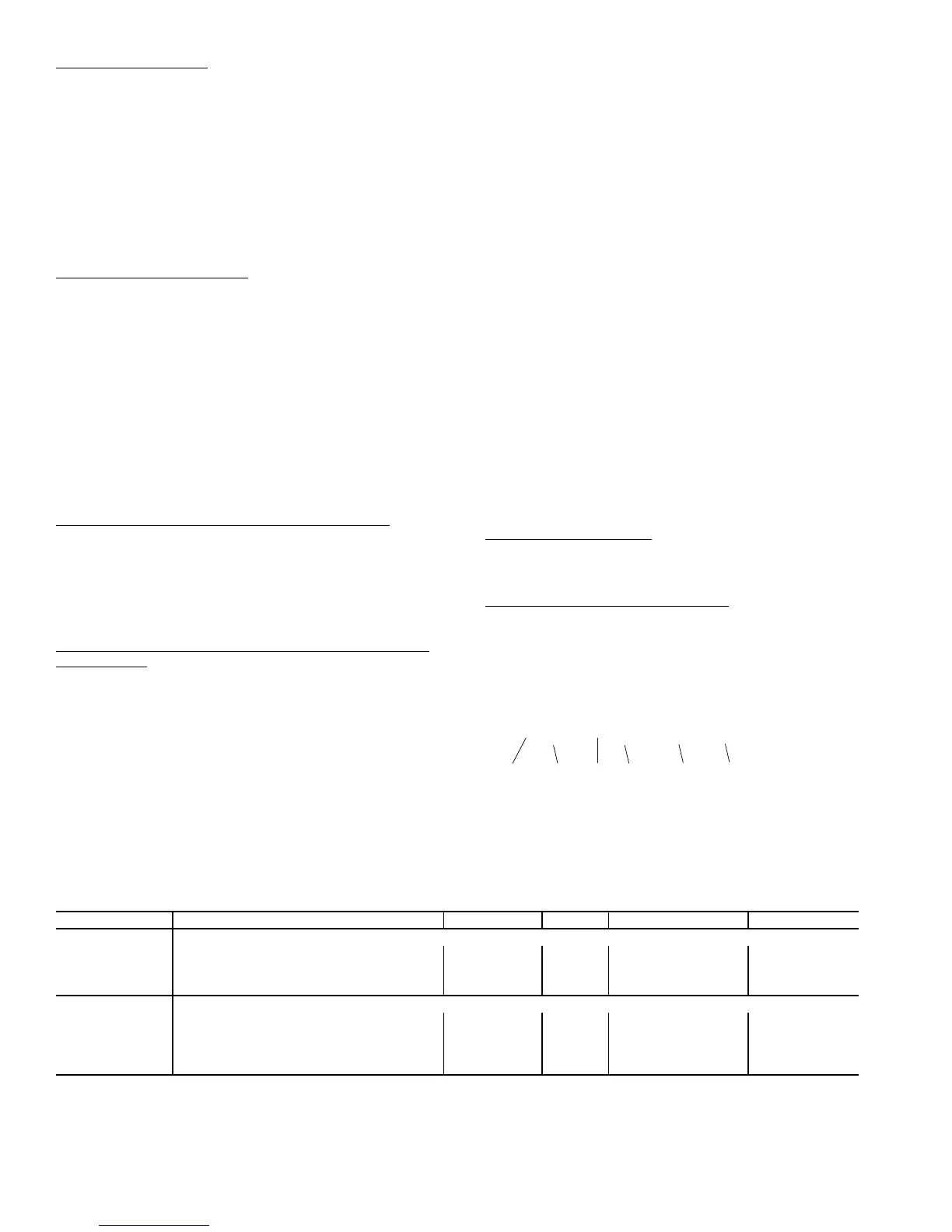

Table 36 — Hydronic Heat Configuration

00850 - 30063 - 084 -083

ACTUATOR SERIAL NUMBER

{

NOT

USED

{

SN.1

{

{

SN.2 SN.3

{

NOT

USED

{

SN.4

SN.1 = 850

SN.2 = 3

SN.3 = 63

SN.4 = 83

Fig. 15 — Actuator Serial Number Configuration

a48-8507

ITEM EXPANSION RANGE UNITS CCN POINT DEFAULT

HH.CF HYDRONIC HEAT CONFIGS

HW.P Hydronic Ctl.Prop. Gain 0 - 1.5 HW_PGAIN 1

HW.I Hydronic Ctl.Integ. Gain 0 - 1.5 HW_IGAIN 1

HW.D Hydronic Ctl.Derv. Gain 0 - 1.5 HW_DGAIN 1

HW.TM Hydronic PID Rate Config 15 - 300 sec HOTWPIDR 90

ACT.C HYDR.HEAT ACTUATOR CFGS.

SN.1 Hydronic Ht.Serial Num.1 0 - 9999 HTCL_SN1 0

SN.2 Hydronic Ht.Serial Num.2 0 - 6 HTCL_SN2 0

SN.3 Hydronic Ht.Serial Num.3 0 - 9999 HTCL_SN3 0

SN.4 Hydronic Ht.Serial Num.4 0 - 254 HTCL_SN4 0

C.A.LM Hydr.Ht.Ctl.Ang.Lo Limit 0-90 HTCLCALM 85

Loading...

Loading...