36

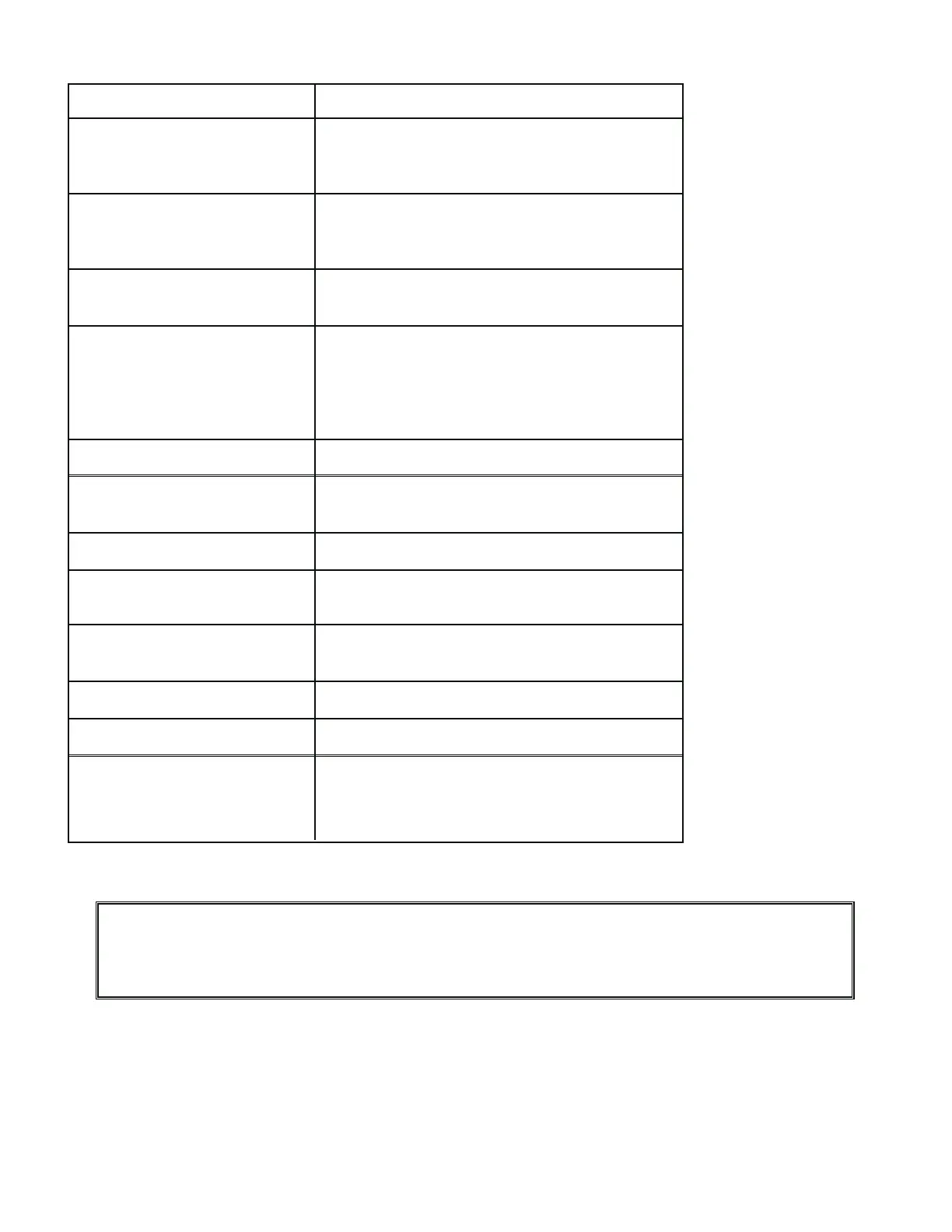

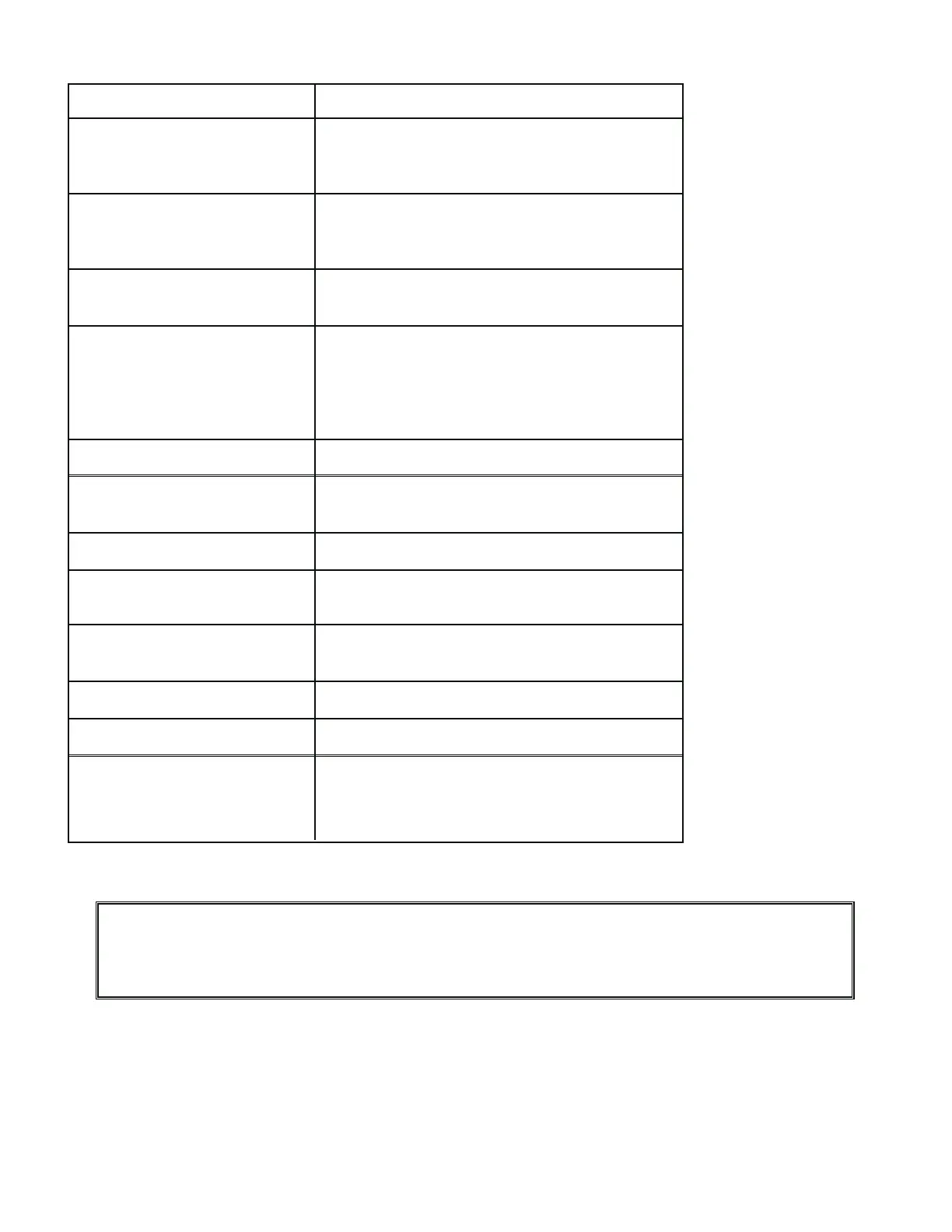

Troubleshooting

Problem Possible Cause

Wash station overfl ows Wash station clogged

Tubing clogged

Waste tubing crimped

“No Flow Detected” error No water available to system

Crimped tubing

Replace fi lter

No iTAG added Crimped tubing

Cap tightened on iTAG bottle

Erratic Results Inconsistent sample size

Sample on side of sample cup

iTAG not stirring

Dirty Optics

Balance problems

Waste pump tubing leaking Incorrect tubing size. Replace tubing

Unit-to-unit variability in results Improper iTAG reference (re-run Gold Standard)

Refer to “Erratic Results”

Water in system “steams” Improper heater calibration

Instrument not seeing fi rmware USB cable unplugged from CPU board

Firmware not in the CEM/Sprint/Install directory

iTAG splattering in sample cup Dirty homogenizer

Homogenizer bearing require replacement

Water splashing in wash station Pressure not properly set (10 - 15 psi)

Rising pressure Debris in regulator (Open, fl ush (clockwise), reset)

Protein result too high/low Verify protein reference (Kjeldahl, etc.)

Restandardize iTAG

Dirty optics

Dirty homogenizer

For service and repair, contact the CEM Service Department or local CEM susbsidiary or distributor.

WARNING

This instrument utilizes high voltages. Instrument service and repair should be performed only by techni-

cians trained in repair and maintenance of high voltage systems.

Loading...

Loading...