4-3

0

1

2

3

4

3

6

7

8

9

10

11

12

13

14

15

16

17

18

WIRE HARNESS AND CONNECTOR INSPECTION PROCEDURE

When any trouble occurs, first inspect the connectors and wire harness of the related circuit according to

the following procedure:

Continuity check

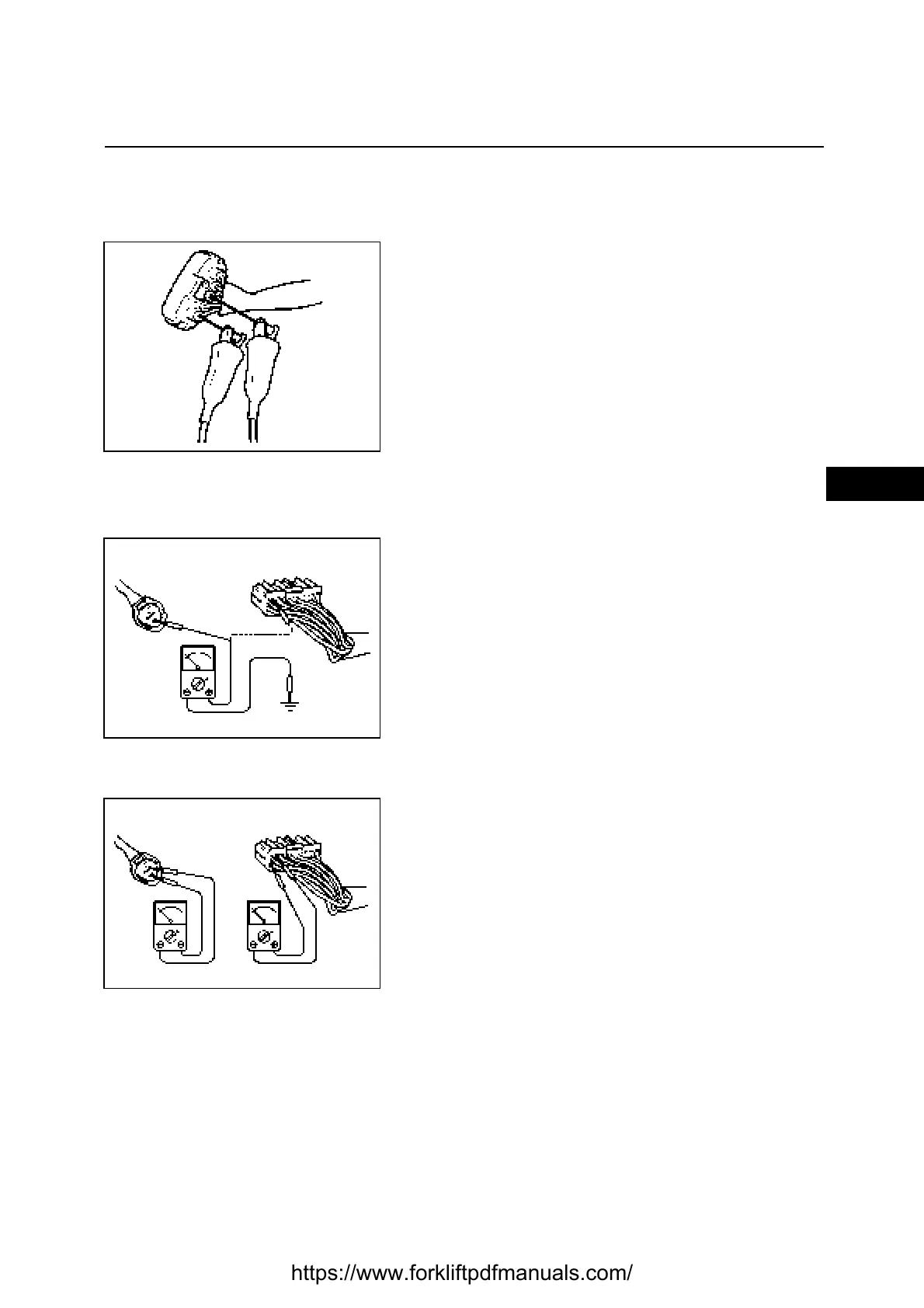

1. Disconnect the connectors at both ends of the

corresponding harnesses

2. Measure the resistance between corresponding

terminals of the connectors at both ends.

Standard: 10 Ω or less

Remarks:

Measure while lightly shaking the wire harness up and

down and sideways.

Reference:

Open circuit at the wire harness occurs rarely partway

through a vehicle wiring but mostly at connectors.

Inspect especially the sensor connectors with sufficient care

Short circuit check

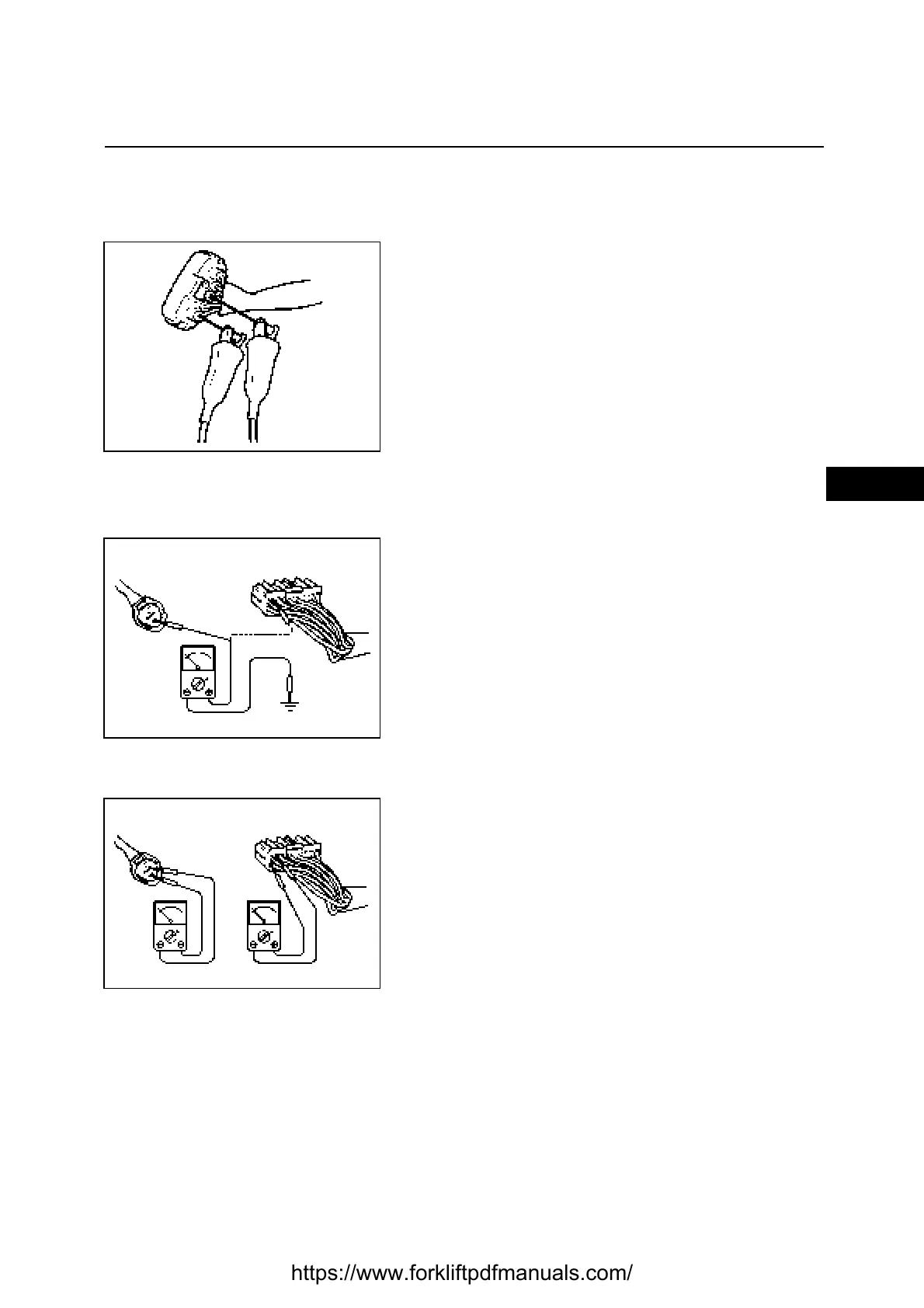

1. Disconnect the connectors at both ends of the

corresponding harness

2. Measure the resistance between the corresponding

connector terminal and negative. Always inspect the

connectors at both ends

Standard: 10 MΩ or more

Remarks:

Measure while lightly shaking the wire harness up and

down and sideways.

3. Measure the resistance between a terminal

corresponding to the connector terminal and N1. Always

inspect the connectors at both ends.

Standard: 10 MΩ or more

Remarks:

The wiring may short-circuit due to pinching by the body

or defective clamping.

https://www.forkliftpdfmanuals.com/

Loading...

Loading...