CVT Drive and brake system

72

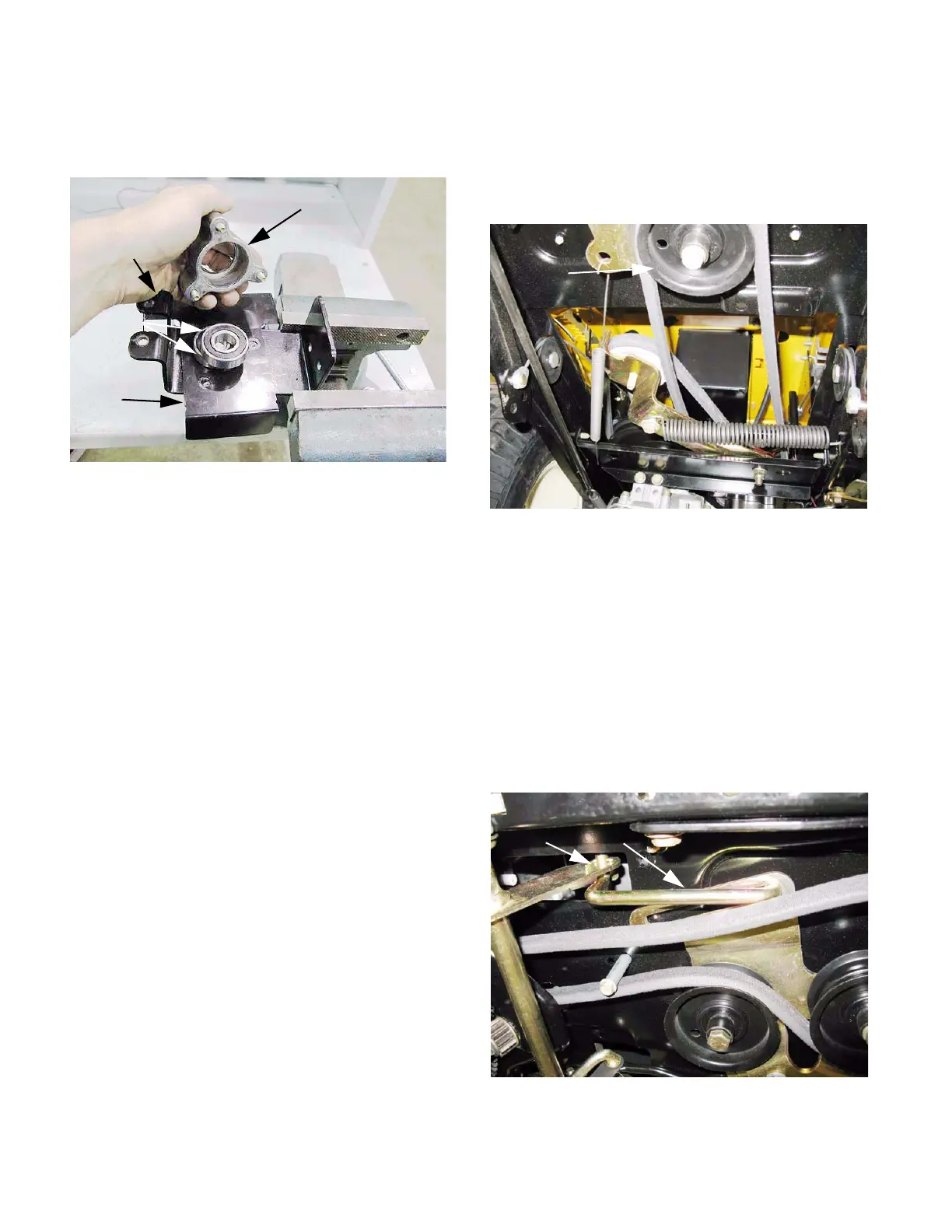

9e. Remove the three screws that fasten the

bearing holder to the bracket, and lift away

the bearing holder. See Figure 6.47.

9f. Inspect the bearings and variable speed

pulley.

• The bearings should turn smoothly, with no

unusual noise.

• The variable speed pulley should spin true in the

bearings.

• The center partition of the variable speed pulley

should slide up-and-down smoothly.

9g. Reassemble the variable speed pulley by

reversing the steps used to disassemble it.

10. Reinstall the variable speed pulley assembly in

the tractor by reversing the steps used to

remove it.

• Apply thread locking compound such as Loc-

Tite

TM

242 (blue) to the variable speed pulley

bolt. Tighten the bolt to a torque of 150-180 in-

lbs (17-20 N-m).

• Tighten the bearing holder screws to a torque of

90-135 in-lbs (10-15 N-m).

11. Run and test the drive system before returning

the tractor to service.

Belt control: tensioner pulleys

NOTE: The V-pulley can be removed from below

using a 1/2” wrench, with no disassembly

beyond removing the cutting deck.

See Figure 6.48.

NOTE: Confirm that the parking brake is

released before starting work.

1. Remove the mowing deck.

2. Remove the fenders, as described in the body

panels chapter of this manual.

3. Disconnect the rod that joins the arm at the left

side of the clutch/brake shaft to the drive belt

tensioner pulley bracket. See Figure 6.49.

• Remove and discard the cotter pin to disconnect

the rod.

Figure 6.47

Bearing cover

Bracket

keeper

Belt

Bearings

Figure 6.48

V-pulley

Figure 6.49

Cotter pin Rod