CVT Drive and brake system

79

Belt installation notes:

• Install only correct OEM belts.

Incorrect belts may cause problems that effect

the performance and/or safety of the tractor.

• Apply a small amount of anti-seize compound to

the engine crankshaft before installing the crank-

shaft pulley.

• Apply a small amount of thread locking com-

pound such as Loctite 271

TM

(red) to the threads

of the crankshaft bolt.

• Tighten the crankshaft bolt to a torque of 36-50

ft-lbs (50-68 N-m).

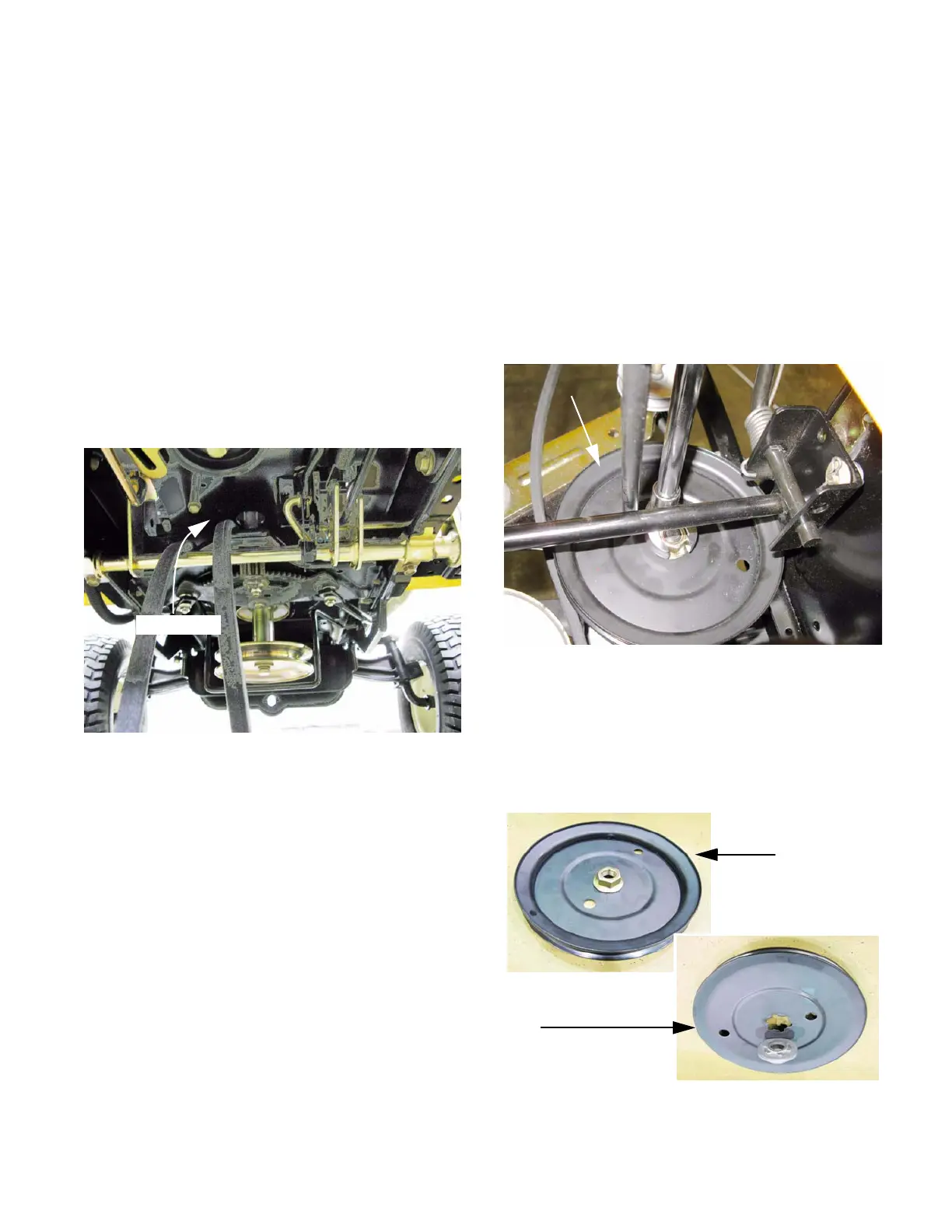

• The belt is routed to the left of the steering shaft,

and the fore-most keeper pin goes between the

runs of the belt. See Figure 6.73.

7. Thoroughly test the operation of the drive sys-

tem and all safety features before returning the

tractor to service.

Figure 6.73

Belt routing

Transaxle removal and replacement

CAUTION: The battery will be removed in this

procedure. Review the Operator’s Manual and

the Electrical chapter of this manual for impor-

tant safety information about handling batteries

before proceeding.

1. Remove the upper drive belt as described in the

drive belt replacement section of this chapter.

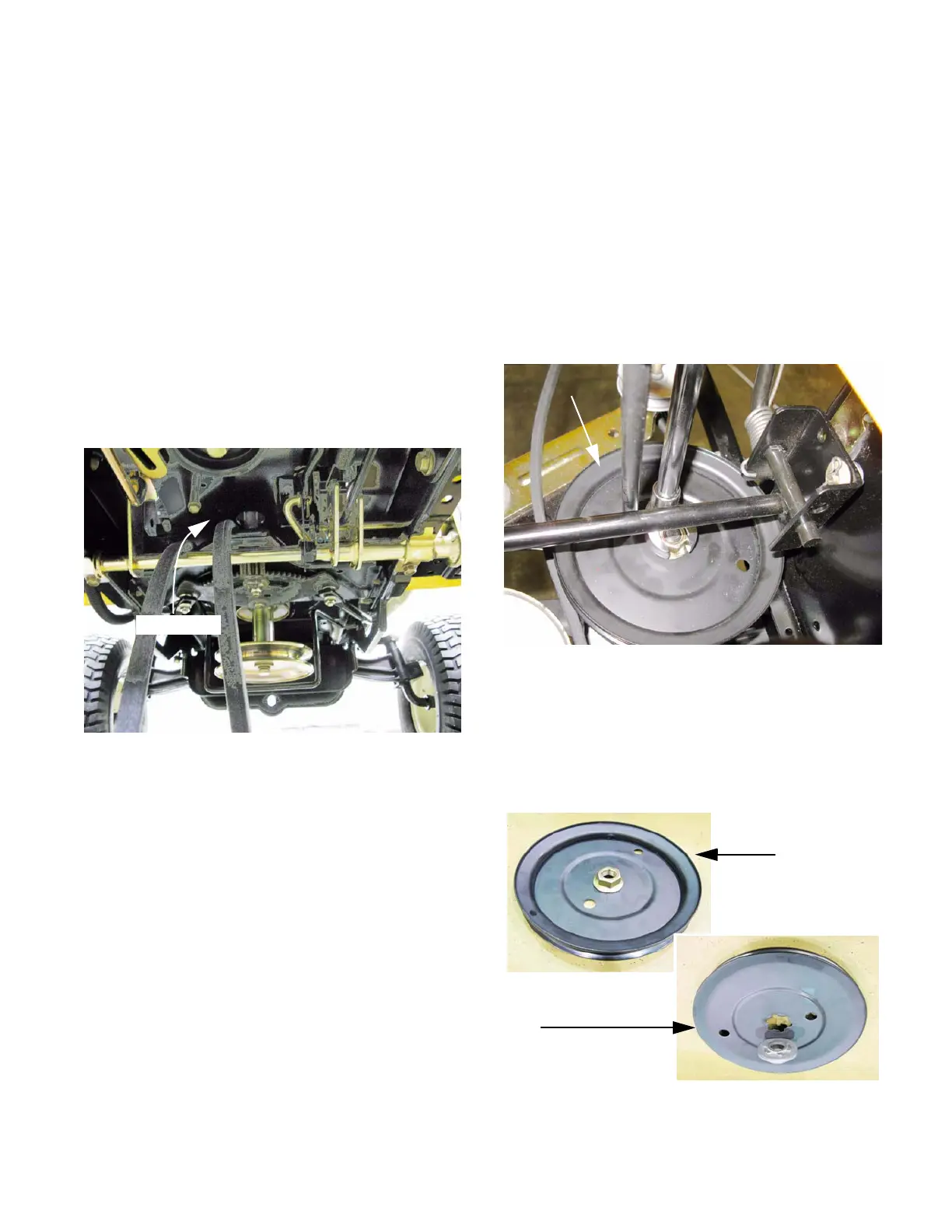

2. Remove the input pulley and input pulley adap-

tor from the transmission using a 7/8” wrench.

See Figure 6.74.

NOTE: A crow foot wrench with a long exten-

sion works well for this step. Use a tapered pin

to keep the pulley from rotating.

NOTE: The recessed side of the pulley faces up.

See Figure 6.75.

Figure 6.74

Input pulley

Figure 6.75

Top

Bottom

Loading...

Loading...