Design Guide | iC7 Series Liquid-cooled System Modules

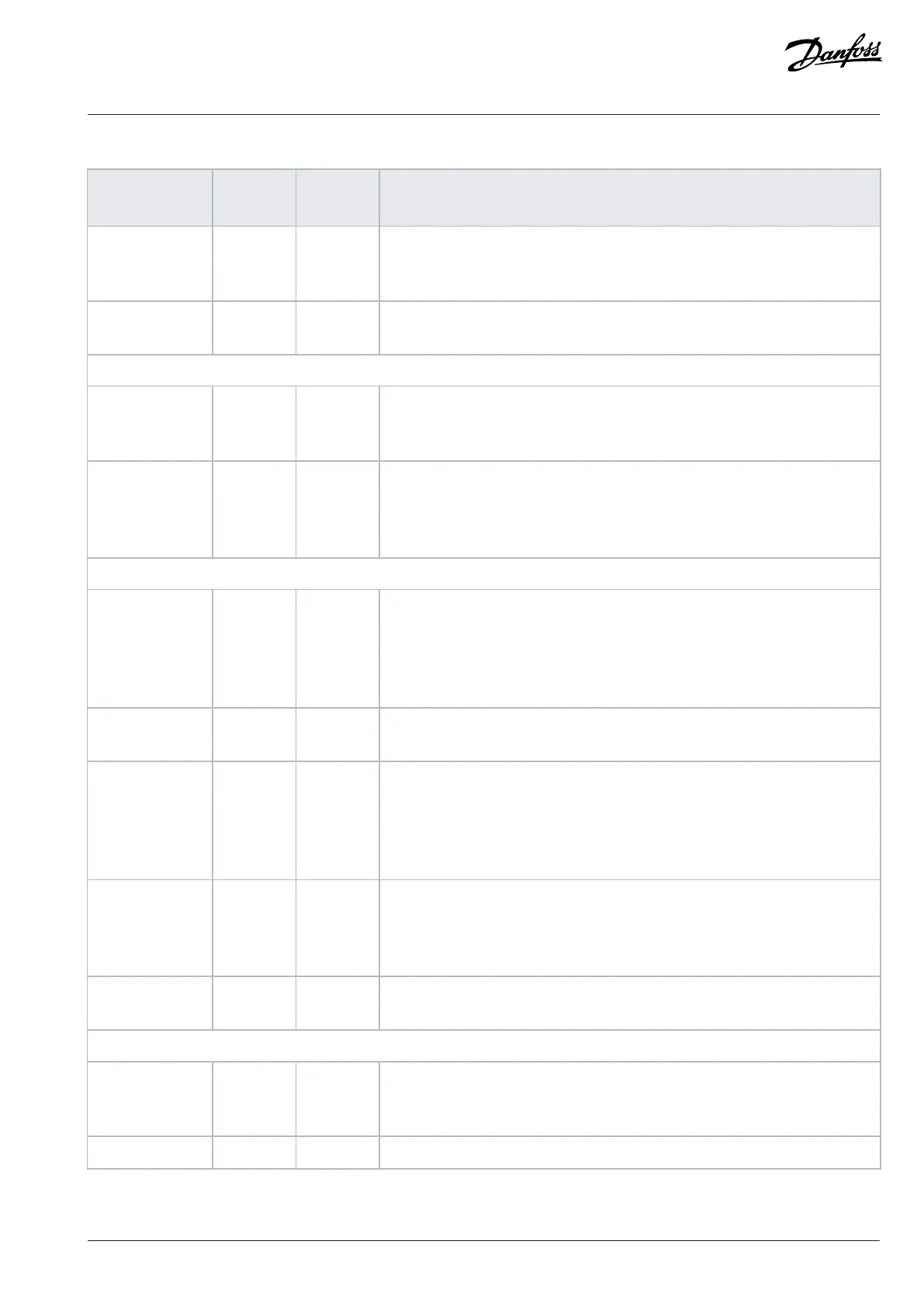

Table 42: Maintenance Schedule for Liquid-cooled Drives (continued)

Component Inspection

interval

(1)

Service

schedule

(2)

Preventive maintenance actions

Insulator gaskets 1 year 10–15

years

Inspect the insulators for signs of degradation due to high temperature and ag-

ing. Replacement is based on findings or done at the same time as DC capacitor re-

placement. Only trained service personnel are allowed to perform this action.

Batteries 1 year 7–10 years Replace the batteries according to the manufacturer recommendation. Replace the

real-time clock battery in the control unit every 7–10 years.

Spare parts

Spare parts 1 year 2 years Stock spares in their original boxes in a dry and clean environment. Avoid hot stor-

age areas. Electrolytic capacitors require reforming as stated in the service sched-

ule. The reforming must be performed by trained service personnel.

Exchange units 1 year 2 years Visually inspect for signs of damage, water, high humidity, corrosion, and dust

within the visual field of view without disassembly. The exchange units with

mounted electrolytic capacitors require reforming as stated in the service schedule.

The reforming must be performed by trained service personnel.

Coolant

Log Commissio

ning/startu

p, or when

replacing

coolant

– To create a baseline for future reference before and after adding inhibitor and gly-

col, record the water quality specification values. Also, record the system pressure,

coolant flow rate, and temperature range.

Glycols 1 year Based on

findings

Measure and record the level of glycol in the cooling system. The minimum con-

centration level is always 75/25% demineralized water/glycol.

Corrosive in-

hibitors

1 year Based on

findings

Measure and record the level of Danfoss recommended corrosive inhibitor (Cortec-

VpCI-649) in the liquid coolant (see specification). Measure the level of the inhibitor

every year. If the inhibitor level is below the recommended level of 1%, add more

inhibitor. Before adding more inhibitor, practice caution not to exceed the level of

electrical conductivity.

Pre-mixed coolant

with glycol and in-

hibitor

1 year Based on

findings

The pre-mixed coolants contain specific percentages of glycol and inhibitor for

antifreeze and corrosion protection. The advantage of using a pre-mixed coolant

is that the chemical composition is within Danfoss specifications, and there is no

need for analyzing the coolant.

Demineralized

water

1 year Based on

findings

Only use demineralized or deionized water in the coolant solution. Record and

compare the chemical composition values when replacing or adding coolant.

Liquid-cooling system

Pipes, hoses, and

connections

1 year 1 year Check for external signs of moisture, corrosion, and coolant leaks. Check the tight-

ness of the cooling pipe connections. Check the heat sinks and host pipes in the

cooling system.

Leak detector 1 year 10 years Test the functioning of the leak detector.

Danfoss Drives Oy © 2024.03 AJ475942178716en-000101 / 172K2848A | 115

Loading...

Loading...